Training at the Center

SCHREINER PROTECH

Training at the Center

Printing, milling, cutting: The training center perfectly prepares Schreiner Group’s young talents for their vocational careers. What started as a simple workshop has evolved into a center for four different technical apprenticeships. The high-tech company invests in the future of young people, so setting the course for further successful growth in times of skills shortage.

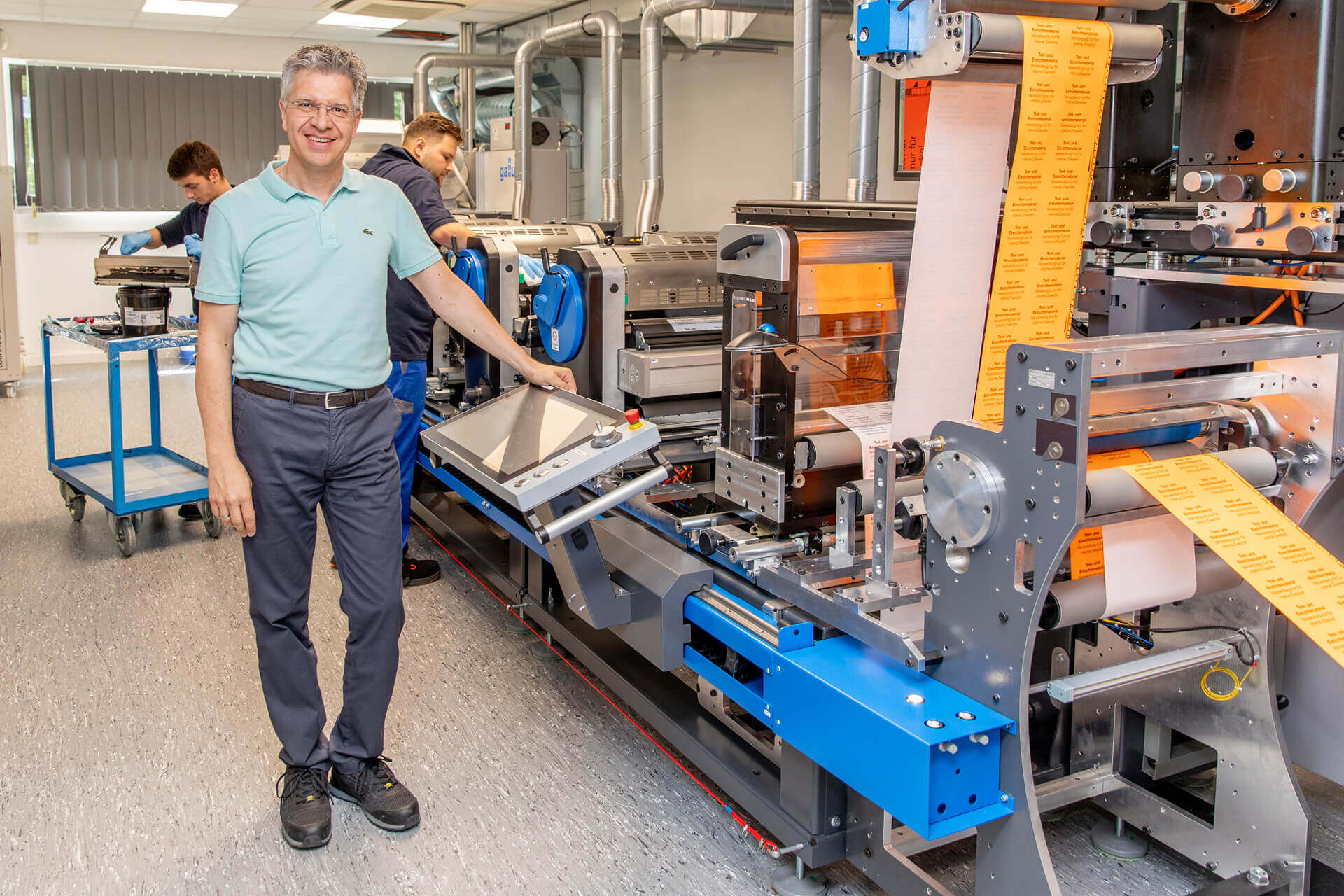

Michael Limmer can be proud. The printing machine behind him is whirring in step. Two apprentices are working with inks and tools while another one is carefully examining the printing results. Two years ago, Schreiner Group opened its own training workshop. Now, it has become a full-fledged training center with workshops for media technicians, machine operators, mechatronics specialists, and industrial mechanics. “We moved into the new facility with our apprentices only in spring. Now, we have a third more space,” says Michael Limmer. He oversees the workshop for media technologists and machine operators.

Industrial Mechanics and Mechatronics Specialists: A Workshop for Dedicated Projects

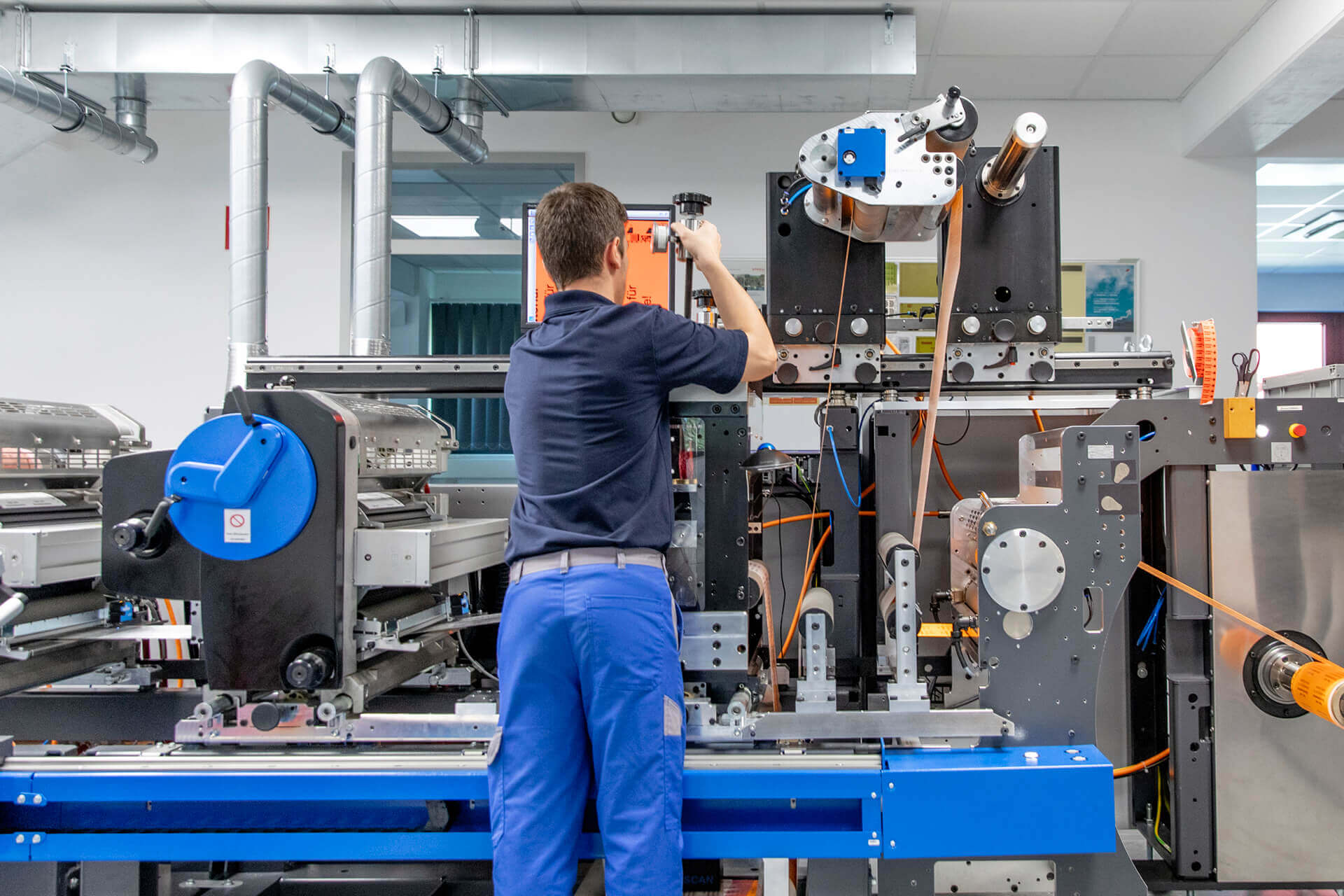

The second part of the training center is located across the street. That is where the mechatronics specialists and industrial mechanics learn their trade. The talent cradle is operated by the machine optimization/ operational safety team of the Industrial Engineering function. “Since November 2023 we’ve had our own workshop which in addition to our production operation is used for training purposes. This is where our apprentices have all the opportunities for working on their own projects—be it for vocational school, Schreiner Group, or even for customers,” say the training representatives Christian Weiser and Mirko Grünheid. There are workplaces for filing and soldering jobs, for metalworking, and for inspections, etc.; an assembly area, guillotine shears, and a milling machine. “Plus, we’re planning to make the workshop even bigger and better.” But learning takes place not only on the factory floor: “All apprentices together recently attended an offsite welding course for several days.”

Optimal Conditions: An Apprenticeship with Many Benefits

In September, a total of about 30 apprentices joined Schreiner Group. Six of them are currently being trained as industrial mechanics or mechatronics specialists. The workshop for media technicians and machine operators even has ten apprentices. Even for a high-tech company like Schreiner Group filling all apprenticeship slots is a challenge. But thanks to the outstanding conditions there, the company in 2024 again managed to find very good candidates for all vacancies: During their apprenticeship the young talents receive intensive and personal support, 30 days of vacation, and the opportunity to take part in joint apprenticeship days and company events. With its training center, Schreiner Group has achieved a further professionalization of apprenticeship training. Besides the workshops, there are facilities for training sessions, meetings, and modern PC workstations. The high-tech company has repeatedly been recognized for its commitment to training, this time in the 20th Printing & Media Awards in the “Apprenticeship Operation of the Year” category. (The awards ceremony took place after the editorial deadline for this issue).

The Printing Pros of Tomorrow: A Peek into the Workshop

“Our apprentices used to get started directly on the factory floor,” Michael Limmer recalls. “However, since they were still lacking basic skills, they couldn’t be part of the workflow. That repeatedly led to conflicts of interest on the factory floor with its tight schedules. Today, they operate the machines themselves and are allowed to learn from their mistakes.” Schreiner Group invested a lot of money in the equipment to make that happen. In 2022, the company bought a modern printing machine, a Gallus Labelmaster 440, and a new die-cutting machine—just for training purposes. They’ll be followed by another five-color printing machine for the future media technicians. In addition, the workshop is equipped with measuring tools, a cross cutter, and quality inspection machines. Four experienced employees continuously support the apprentices.

That about 11 percent of the current employees started their careers here as apprentices is one of the facts showing how important apprentice training has been for Schreiner Group for a long time. Because most of the apprentices transition into permanent jobs after their apprenticeships— and want to stay. In recent years, not only the number of apprentices has kept growing but so has the number of vocational jobs in which apprentices are being trained. Currently, more than 60 young talents are enrolled in one of 14 different specialized apprenticeships at Schreiner Group. For many, their future career starts right here: at the training center.