The pilot plant: Innovation engine in the background

SCHREINER GROUP

The pilot plant: Innovation engine in the background

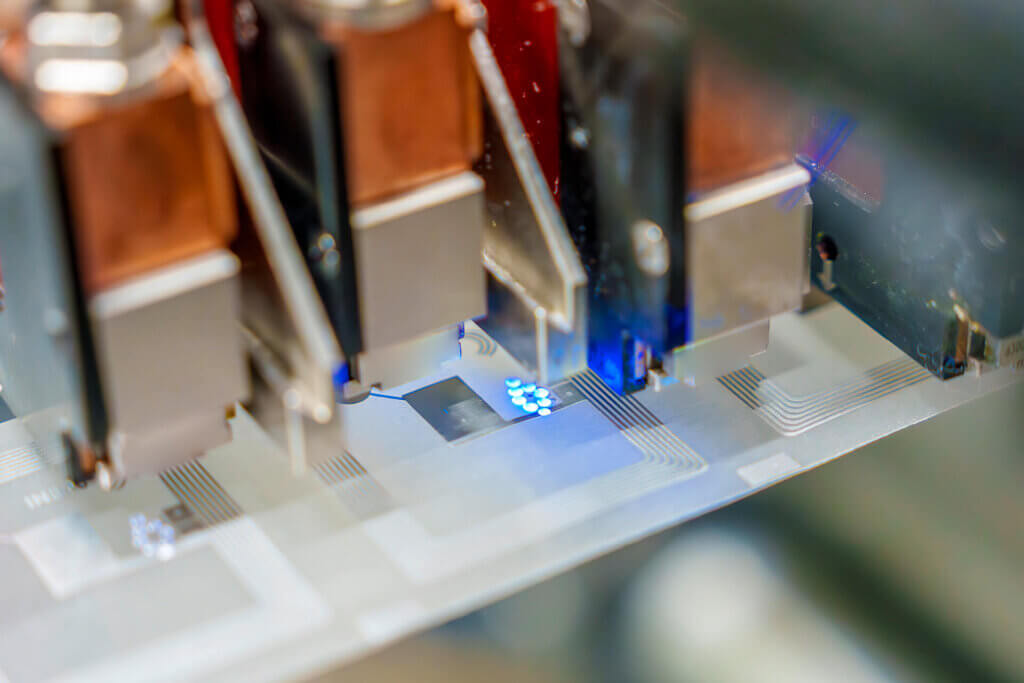

Whether hybrid technology (the combination of different printing methods), laser cutting, or sustainable materials—before new manufacturing technologies are adopted for regular production at Schreiner Group they pass through a central testing facility: the company’s in-house pilot plant. The things being developed, tested, and optimized day in day out often stay behind the scenes—but are decisive for the company’s technological progress.

Putting it in a nutshell, “Our job is to break new ground—systematically,” says Dr. Edgar Hecht, Head of the Pilot Plant, “because whether a new technology is technically and economically feasible is a question that cannot be decided on a drawing board. It takes know-how, experience—plus the opportunity to run extensive serial testing under realistic conditions.”

That’s exactly what the pilot plant provides: This is where new technologies such as hybrid printing using UV inkjet inks are intensively tested—long before being rolled out on the factory floor. In that way, Schreiner Group has been able to draw on detailed knowledge of ink systems, varnishes, materials, and process parameters. “Extensive trial programs would not be possible in the production environment,” Hecht explains. “Operations would have to be shut down for that purpose—while we can perform flexible and profound analyses.”

The pilot plant is far more than an in-house test laboratory. It’s a strategic innovation partner forging links between research, development, and the shop floor. Whether it’s creating printed protective structures for robust RFID application or pre-qualifying new inks or varnishes—often with a view of changed legal requirements—the pilot plant provides valid bases for decisions for the next stage. Currently, sustainability plays a key role as well. New more eco-friendly materials are put through their paces at the pilot plant to systematically reduce the carbon footprint of products—without sacrificing their quality or performance.

The pilot plant’s particular forte lies in its equipment: Only few high-tech printing companies have an equally wide range of technologies and testing opportunities. That’s exactly what external partners value to test and prequalify new technologies. In that way, the pilot plant makes an important contribution to the company’s success—as a reliable scout, experienced tester, and creative enabler.