The Footprint of the Labels

SCHREINER GROUP

The Footprint of the Labels

In 2021, Schreiner Group set itself a strategic sustainability goal: By manufacturing sustainable products we want to achieve climate-neutral production by 2023 and full climate neutrality by 2030. Reaching such ambitious goals presupposes not only various actions but also the concrete calculation of the company’s CO2 emissions. Since the end of 2022, that has been possible also for the individual products.

Sustainability is one of the key issues in general. Schreiner Group realized that decades ago. The company’s air conditioning concept is a case in point: Groundwater has been used for cooling purposes at the headquarters in Oberschleissheim since the 1990s and, since 2012, also for heating using heat pumps. Before the year of 2023 is out, all gas heaters will be exchanged for heat pumps to the tune of more than five million euros. As a result, Schreiner Group will reduce its carbon footprint significantly. But what about the individual products? The high-tech company can now calculate their carbon footprints in detail as well.

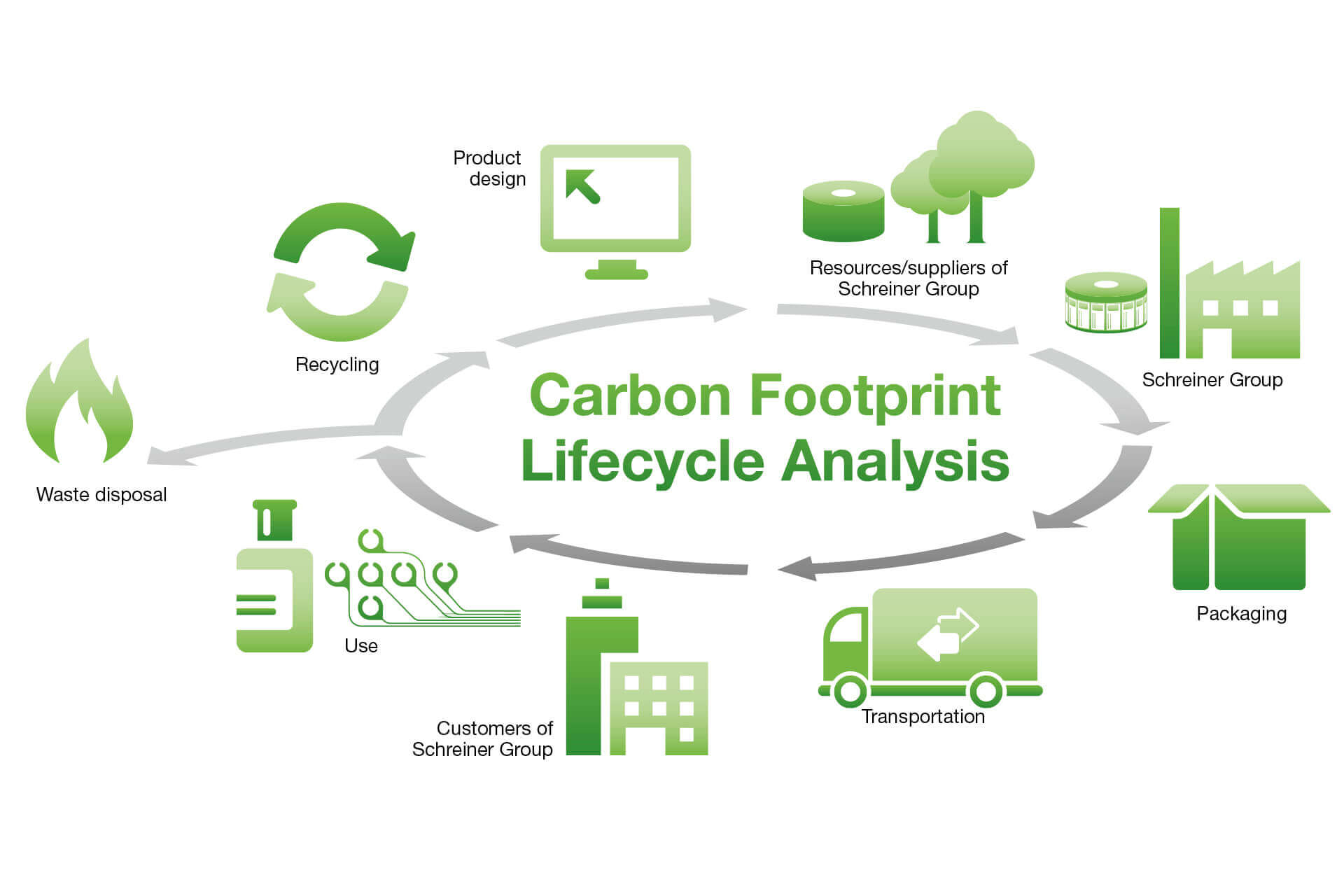

The product carbon footprint (PCF) describes all greenhouse gas emissions that a product causes in the various stages of its lifecycle. It serves as the basis for assessing the impact of a product on the climate and identifying reduction potential for CO2 emissions. “Reporting the product carbon footprint creates transparency for our business partners,” explains Dr. Joseph Adelsberger, a team leader in Schreiner Group’s R+D department. “In addition, it helps us define suitable actions to optimize our product portfolio.” For guidance in calculating PCF data, Schreiner Group uses the Greenhouse Gas Protocol and the ISO 14067 guidelines. PCF calculations are based on a product’s lifecycle analysis in which Schreiner Group can also report different scopes. It means that together with our customers we can select and analyze the scopes in the individual stages of the lifecycle (see infographic) which are then considered in the PCF calculation.

In the B2B field, the PCF is typically calculated based on a cradle-to-gate analysis, which means that all CO2 emissions until the product is shipped to the customer are included—from raw material extraction, their packaging and distribution, to the production processes and the disposal of production waste and transportation activities. When all suppliers in the upstream chain before the final product report their cradle-to-gate contributions the result is a complete picture of the CO2 emissions across the entire product lifecycle. “Today we realize that our sustainability commitment toward climate-neutral production already makes major contributions to CO2 reduction on company and product level,” says Dr. Adelsberger. “We’d still like to receive more extensive primary data from our suppliers regarding raw materials in order to further enhance the database for the PCF calculations. That enables even more targeted identification of CO2 reduction potential across the entire supply chain.”