Sustainably Sealed: Tested Eco-Friendliness

SCHREINER MEDIPHARM

Sustainably Sealed:

Tested Eco-Friendliness

90 percent recycled content–100 percent security: In January 2024, at Pharmapack in Paris, Schreiner MediPharm for the first time presented its sustainable closure seal that meets the requirements of the EU’s Falsified Medicines Directive as well as the PPWR targets for 2040. Extensive tests demonstrate the capabilities of the seal.

On April 24, 2024, the European Parliament adopted the Packaging and Packaging Waste Regulation (PPWR) that is intended to support the transition toward a circular economy. The regulation requires all packaging to be recycable and plastic parts of packaging to have a minimum recycled content obtained from post-consumer plastic waste by 2030. Schreiner MediPharm has risen to that challenge and developed a sustainable closure seal meeting the most exacting demands.

The Objective: Sustainability and Security Combined

The objective of the product development was to achieve a closure solution offering reliable tamper evidence, high transparency, and optimal printability. At the same time, the seal’s carbon footprint was to be significantly reduced and recycling of the cardboard boxes to be enabled without impairing the quality of the recycling paper. Due to extensive in-house as well as external testing, a film-based seal with up to 90 percent of recycled content was developed. It features a multi-tear effect for irreversible first-opening indication and tamper evidence. Integrated security die-cuts produce a film-tear effect while a fiber-tear effect causes the cardboard fibers to tear. Thanks to the highly transparent film material, it does not impair the packaging design—which is an important aspect for pharmaceutical manufacturers.

Best-in-Class: Seal Impresses in Testing

In addition to extensive in-house performance tests, an independent test institute conducted a standard recycling test. The objective was to ensure the compatibility of the seal based on a recycled film with the recycling process of a cardboard box. The results of the CEPI Recyclability Laboratory Test Method – Standard Paper Mill Version 2 showed that the seals made of recycled film achieved a best-in-class rating, i.e., that they do not affect the recycling process. In the macrostickies test that investigates sticky contaminations in the recycling process, the recycled film material even performed clearly better than paper-based seals.

Sustainable Seals Support the Pharmaceutical Industry

Schreiner MediPharm’s sustainable closure solution supports pharmaceutical companies not only in terms of regulatory compliance and achievement of sustainability goals but also in reducing Scope 3 emissions. All that is achieved without impairing the performance, functionality, and transparent look of the closure seals, which are crucial for the wide range of cardboard box surfaces and designs in the pharmaceutical industry.

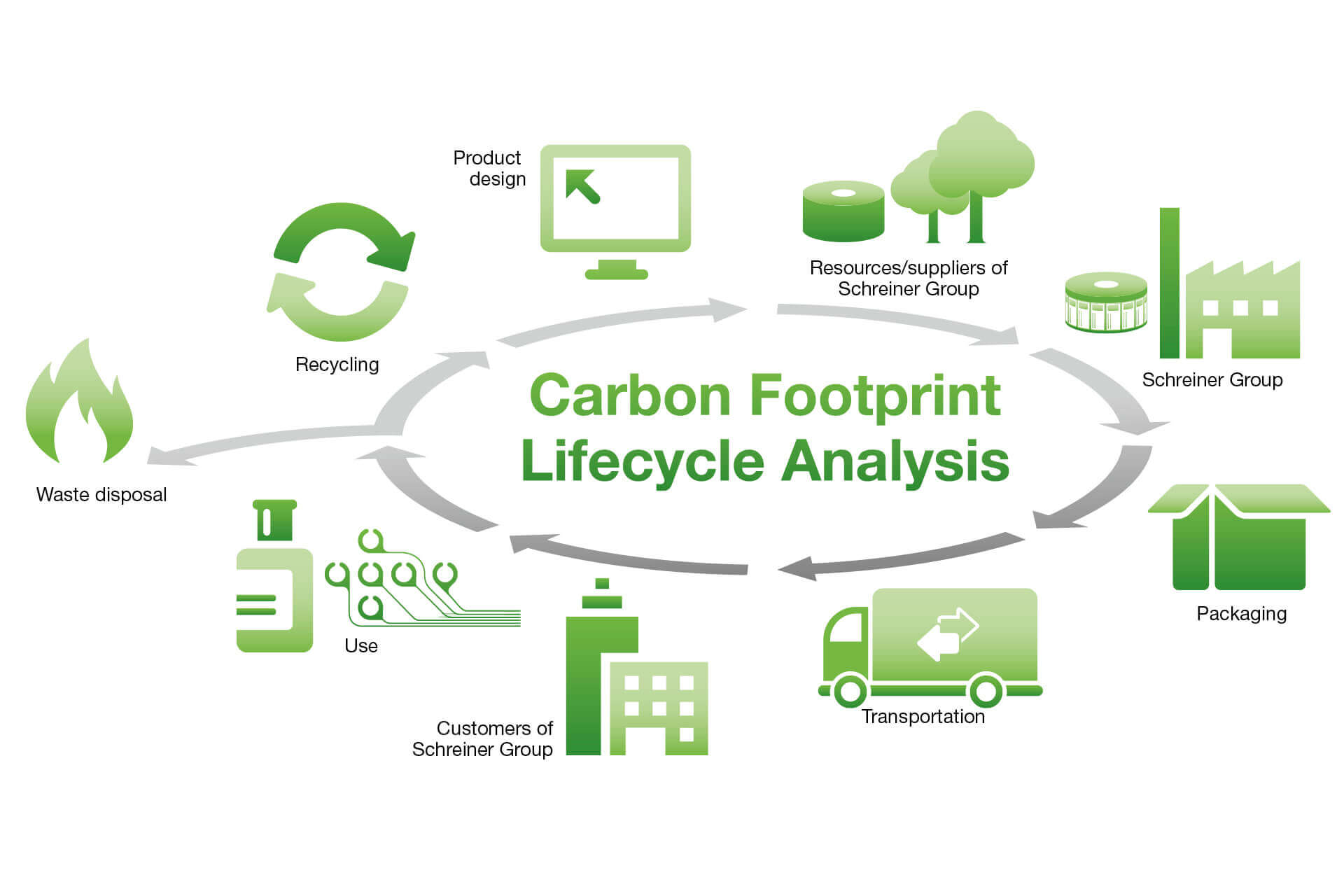

The utilization of this sustainable label solution leads to a CO2 reduction of approximately 28 percent in the face material compared to standard film materials. In addition, the switch from gas to heat pumps at Schreiner Group at the end of 2023 resulted in an additional 35-percent CO2 reduction in label manufacturing operations. With its innovative seal Schreiner MediPharm sets a new standard for sustainable packaging solutions and actively contributes to reducing packaging waste and protecting our environment.

Interested in further background information?

Then request our white paper “Sustainable Tamper- Evident Seals: How to Reduce Environmental Impact Without Affecting Product Performance”: info@schreiner-medipharm.com