Sustainably Bonded: Adhesive Die-Cut Parts

SCHREINER PROTECH

Sustainably Bonded:

Adhesive Die-Cut Parts

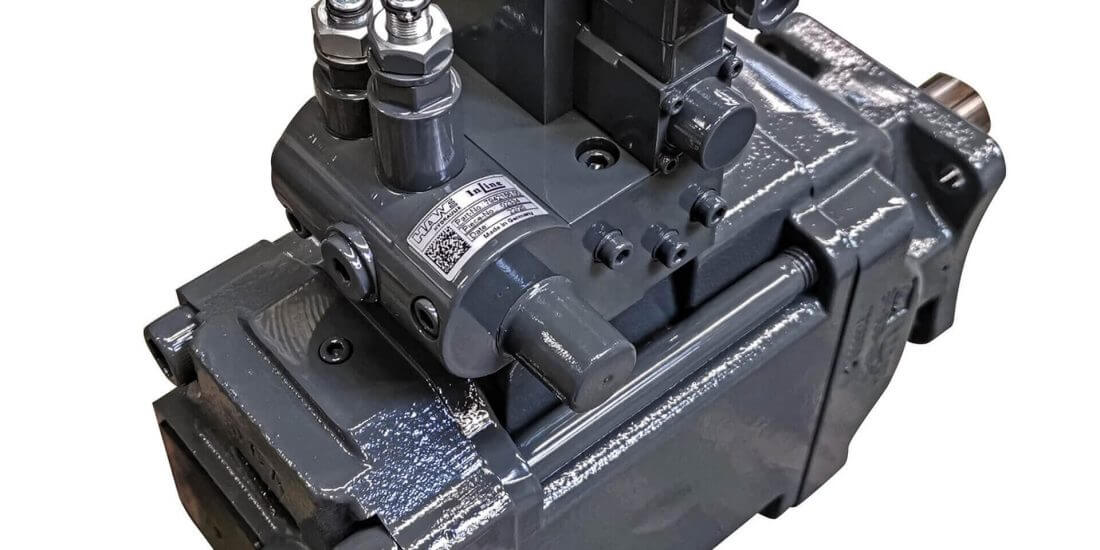

Double-sided adhesive die-cut parts from Schreiner ProTech replace traditional mechanical fastening techniques. These universal talents meet the requirements of increasingly complex production processes.

There are two possibilities for joining components: mechanical methods such as bolting and welding—or adhesive bonding. In many cases, bolting or welding are only suitable for specific requirements and tend to lack flexibility in terms of product design, because modifying a bolt design, tool or drilled hole is complex and costly. By contrast, adhesive bonding solutions are flexible and can be produced in different thicknesses or shapes, which makes it possible to quickly modify a component. In addition, invisible joining allows for greater freedom of design.

However, classic liquid adhesive versions do not always meet the high requirements regarding cleanliness and technical processability. Consequently, manufacturers increasingly opt for pressure-sensitive adhesives in the form Schreiner ProTech 25 of double-sided adhesive die-cut parts, which enable clean, efficient and, ideally, automated processes and can also perform other functions besides joining and fixing components in place.

Maximum Customization: Materials,Adhesives and Sizes for any Requirement

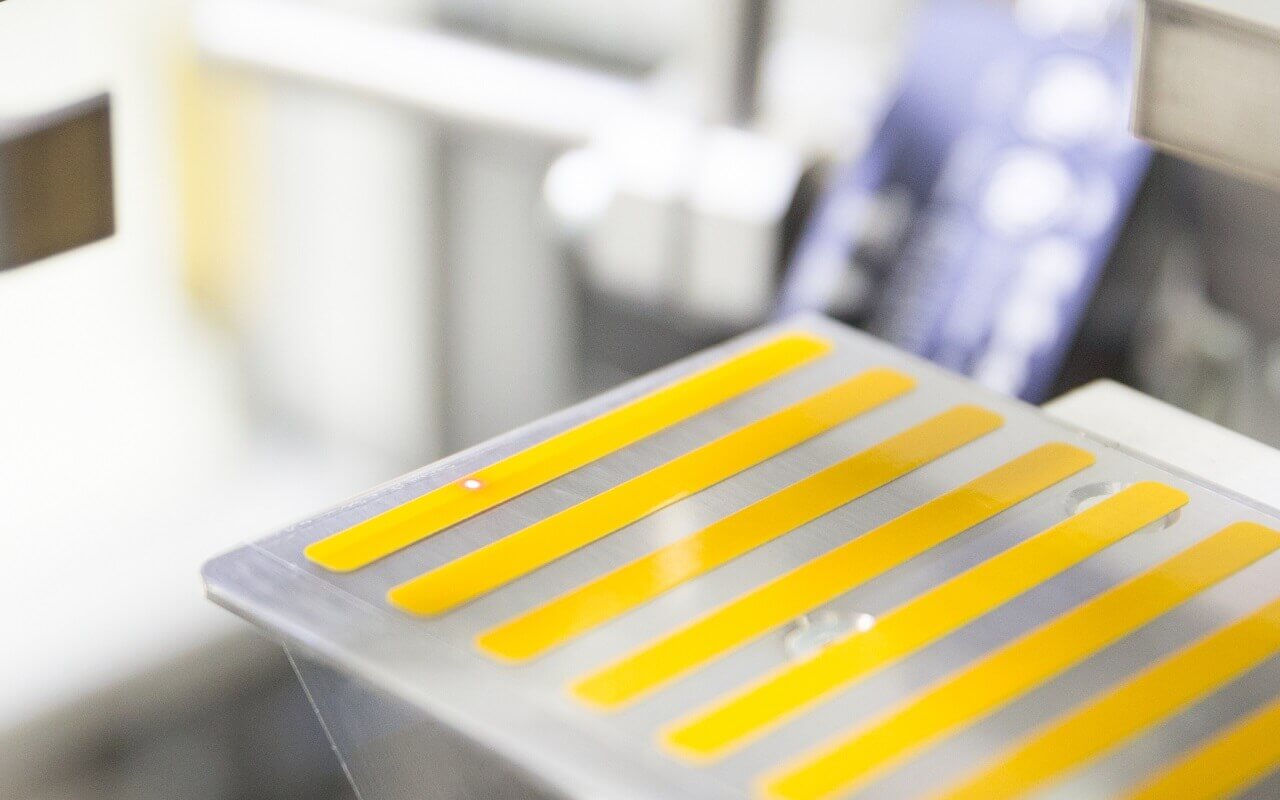

Die-cut parts are categorized as either simple or complex composites using full-surface, partially applied, permanent or removable adhesives. Simple composites are recommended when the aspect of adhesive bonding is emphasized. In these applications, self-adhesive die-cut parts consisting of double-sided adhesive tapes or transfer adhesives are typically used.

Complex composites frequently featuring a multi-layer design are used whenever several functions must be combined in a component such as adhesive bonding, height compensation, temperature compensation and dust protection. The portfolio of available sizes and shapes of die-cut parts is extensive: from miniature formats of just a few millimeters to large dimensions combined with thin frames, complex geometries or diverse interior cutouts. This results in a wide variety of suitable uses for these universal talents.

As Individual as the Product: Forms of Delivery

Die-cut parts are typically delivered on rolls or as single units or sheets and in stacked form. The form of delivery is usually determined by the customer’s specific manufacturing process. Schreiner ProTech assists customers in selecting the system for their preferred form of delivery.

Examples of Applications

Self-adhesive bonding solutions primarily perform the functions of fastening, protection and height compensation. Rain sensors, for instance, are affixed to the inside of windshields using a UV-resistant double-sided adhesive die-cut part. Trim strips in automotive interiors are fastened by means of foam die-cut parts featuring a practical tab and also serving as height compensation. For onboard sound solutions, a double-sided adhesive die-cut part is used for both fastening and protecting sensitive components. In addition, self-adhesive die-cut parts are utilized as processing, assembly and positioning aids. In manufacturing operations where some parts may have to be removed and reinstalled several times, self-adhesive die-cut parts make the jobs of line workers a lot easier.

Self-adhesive bonding solutions yield significant time and cost benefits here. For instance, as assembly aids in welding and soldering processes, the die-cut versions assist in positioning and precisely fixing the components in place by means of individual adhesive dots. That ensures that sufficient soldering paste can subsequently penetrate the spaces between the components for reliable and permanent connection to each other. Double-sided adhesive tapes can also be used as protective first-opening indication on goods in logistics processes: in an attempt to remove them, they cause a destructive effect on the substrate which shows that packaging has been previously opened and the contents may have been tampered with.

Total Solution: Product and System

Schreiner ProTech has extensive know-how in the areas of material and adhesive bonding technologies and draws on the expertise of the Schreiner Services competence center with application and inspection systems. Proven system solutions for precision application of self-adhesive functional parts are reliably implemented. Manufacturer-independent consulting support and project management guarantee utmost functionality, process and manufacturing reliability as well as efficiency: from design to commissioning and from employee training to servicing customer equipment. Schreiner ProTech develops and produces self-adhesive functional parts, advises customers concerning the selection of consumables and supports them in the smooth integration of the application and inspection systems into new and existing manufacturing lines.