Sustainable and Secure: Closure Seals

SCHREINER MEDIPHARM

Sustainable and Secure:

Novel Closure Seals

Schreiner MediPharm is extending its portfolio of security solutions by new sustainable closure seals for pharmaceutical packaging. The tailored seals are perfectly adapted to the respective packaging and specific threat scenarios offering not only reliable functionality but also supporting the pharmaceutical industry’s pursuit of sustainability.

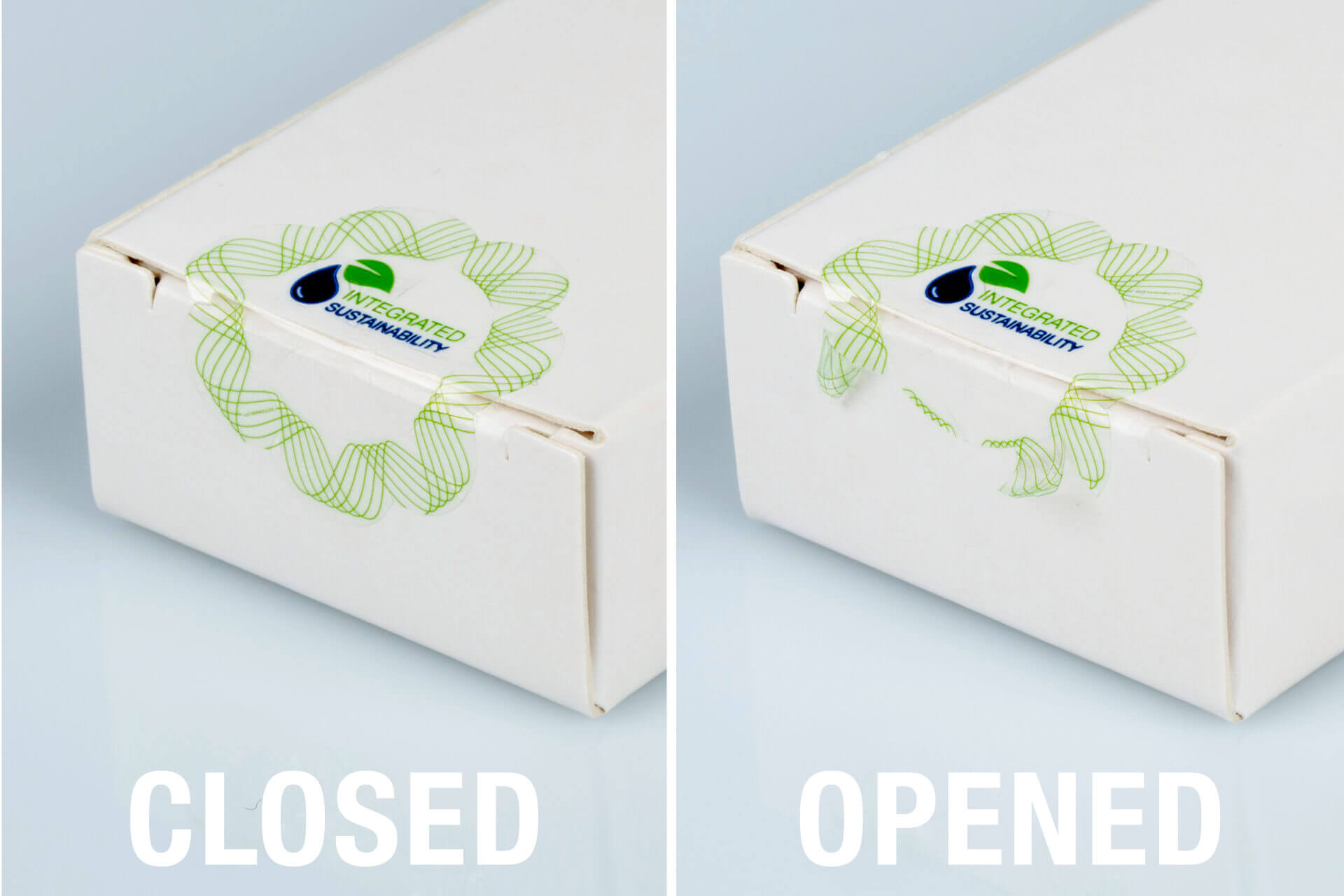

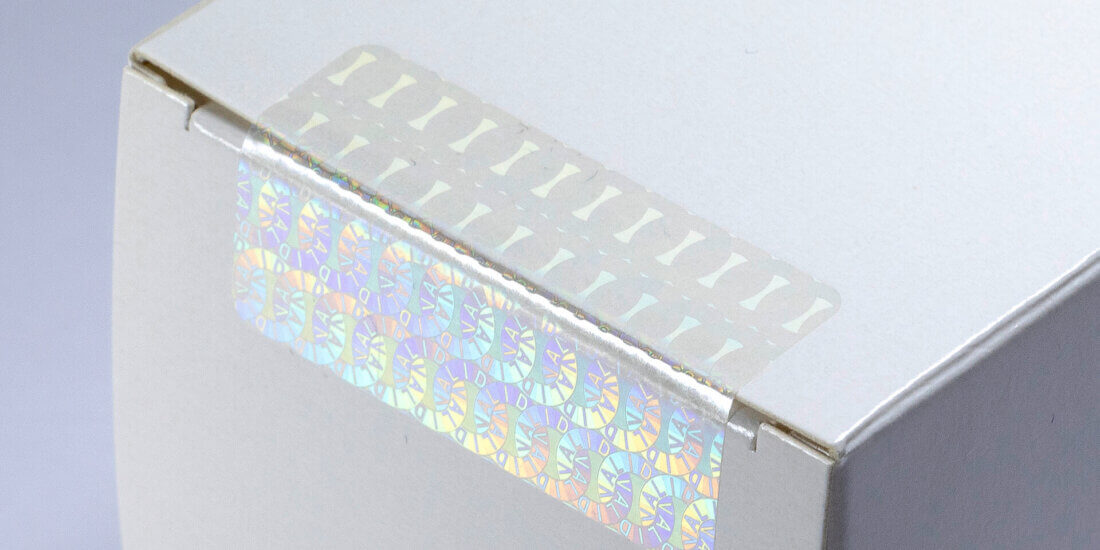

Ever since the EU’s Falsified Medicines Directive has come into effect tamper-proof pharmaceutical packaging has been indispensable. Security seals for secondary packaging are regarded as a proven method for reliable first-opening indication. In view of the growing requirements for a sustainable supply chain, pharmaceutical companies are increasingly seeking suitable solutions.

The planned EU Directive 94/62/EC on packaging and packaging waste regulation (PPWR) sets ambitious targets for waste reduction and demands reusable packaging and use of recycled materials. For instance, a minimum share of post-consumer recycling material (PCR) of 35% starting in 2030 and of 65% starting in 2040 is a proposed target.

Schreiner MediPharm has been offering its customers sustainable product solutions for several years and is extending its portfolio in the spirit of sustainability in this context as well. Now the pharmaceutical expert is presenting an innovative closure seal made of a sustainable material. The seal is based on a high-grade film material with a recyclate content of up to 90%, thus meeting the currently discussed PPWR targets all the way into the year of 2040.

The development of sustainable seals poses a challenge because the functionality and tamper protection of the labels needs to continue to be ensured. Schreiner MediPharm in collaboration with the Schreiner ProSecure competence center has conducted comprehensive tests to qualify the optimally suited material. The tests demonstrated performance comparable to conventional seals in terms of high transparency, optimal printability, and high reliability of the first-opening indication for the sustainable seal.

Switching from conventional materials to sustainable upper materials made of recyclates leads to a reduction of CO2 emissions by about 28 percent on film level. In the product carbon footprint assessment, emission reductions of up to 35% can be achieved because at the end of 2023 modern heat pumps replaced the previous gas heaters at Schreiner Group. The heat pumps are operated with green electricity which the company has been using since as far back as 2013.

Schreiner MediPharm’s sustainable closure seals not only offer security and reliable tamper evidence but also clearly point the way toward the future of the pharmaceutical packaging industry—a future based on environmental compatibility and sustainable innovation.