Strong Partners for Sustainability: Alliance to Zero

SCHREINER MEDIPHARM

Strong Partners for Sustainability: Alliance to Zero

The Alliance to Zero (A2Z) was founded by eight companies along the pharma supply chain to support the transition of the pharmaceutical industry to net-zero emissions. Besides Ypsomed and Schreiner MediPharm, Dätwyler, Harro Höfliger, HealthBeacon, Körber Pharma, SCHOTT, and Sharp are members. Sebastian Gerner from Ypsomed and Dr. Kurt Kugler from Schreiner MediPharm provide insights into the alliance. *

A2Z was founded in June 2021. Why are you a founding member and what are the general goals?

Sebastian Gerner, Ypsomed (SG): Following the launch of the sustainable YpsoMate® Zero autoinjector, Ypsomed realized that close collaboration within the supply chain is necessary to achieve the established climate goals. That’s why we approached our strategic network partners to create A2Z. Its major objective is to add value for our pharma customers by exploring ways in which we can achieve net-zero emissions.

Kurt Kugler, Schreiner MediPharm (KK): Sustainability is an important forward-thinking topic for Schreiner MediPharm, not only since A2Z was founded. By working together with other top players in the pharma supply chain we can systematically implement this lighthouse project. By developing and producing sustainable label solutions we aim to achieve our climate goals and support our customers with their sustainability projects. A2Z wants to transform the linear supply chain into a circular one. Obviously, sustainable labels play a key role in that regard.

What is the benefit of a membership and where do you see the benefit for your customers?

SG: In A2Z, we engage in exchanges about climate-related topics, develop, for instance, joint SBTi (Science Based Targets initiative) goals, or work on end-of-life solutions for our products. Our customers benefit from the fact that as members we speak the same language, jointly pursue the decarbonization of the supply chain, and solve problems together.

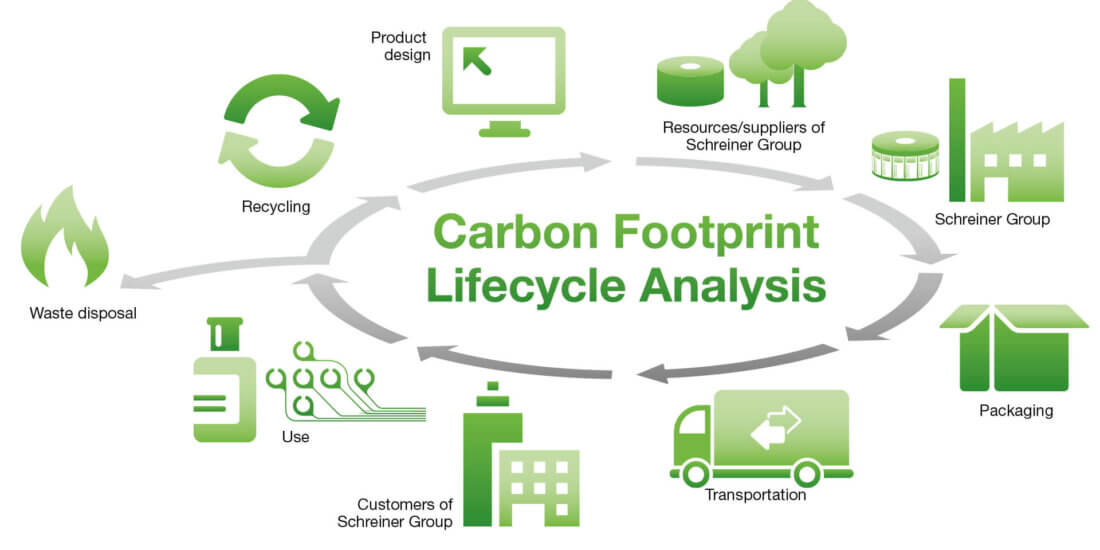

KK: The professional exchange and particularly the close cooperation with experts enables us to answer the complex questions around sustainability in faster and more focused ways. The coordination of key criteria such as the selection and combination of materials, the basis for Product Carbon Footprint (PCF) calculations, the regulatory environment, applicable recycling regulations, etc. occurs directly between the partners and ultimately serves as a benchmark for the pharma industry.

What milestones have been achieved since the alliance was founded and what are the next specific goals?

SG: The first milestone no doubt was the foundation of A2Z as a showcase project for a sustainable supply chain. Since then, together with a consulting firm, we managed to develop a guideline for calculating PCF values that combines all applicable regulations. Based on that guideline, we jointly calculated the PCF value for the YpsoMate® autoinjector enabling us to define actions to reduce the CO2 emissions of an autoinjector to zero. The goal is the production of an YpsoMate® Zero as a pilot project of the alliance.

Is there already a specific action plan based on PCF calculations?

SG: We’ve identified CO2 emissions reduction potential of approximately 70% and linked more than 70 individual actions with it that we plan to pursue together.

KK: Due to the detailed action plan, initial sub-projects between alliance members already exist. They use synergy effects to jointly reduce CO2 along the value chain and to work on the net-zero goal. Regular reporting on the progress of the individual actions within the alliance supports targeted collaboration.

What is your company doing to reduce CO2 emissions?

SG: Ypsomed has committed to achieving net-zero emissions (Scope 1–2) within the company by 2030 and across the entire value chain (Scope 1–3) by 2040. That’s why Ypsomed is pursuing a circular product design that minimizes the environmental impact of self-medication along the supply chain. We’ve launched a Zero Carbon program in which all product groups are converted to sustainable materials such as bioplastics and packaging made from recycled plastics.

KK: Schreiner Group has defined climate-neutral production starting in 2023 as a strategic sustainability goal and achievement of full climate neutrality by 2030. CO2 emissions concerning Scope 1 and 2 have been reduced by more than 70 percent since 2012, and a reduction by another 50 percent is planned for this year. Our CO2 reduction programs are focused on the generation and expansion of renewable energies, reduction of energy consumption, purchasing of green electricity, increase of material efficiency, and manufacturing of sustainable products.

Are there already any initial sustainable product developments by your company?

SG: The YpsoMate® Zero from Ypsomed is the world’s first CO2 emission-free prefilled autoinjector. The YpsoMate® autoinjector platform is being converted to biopolymers and the packaging design adapted in order to reduce emissions. The remaining emissions are compensated for by carbon removal certificates.

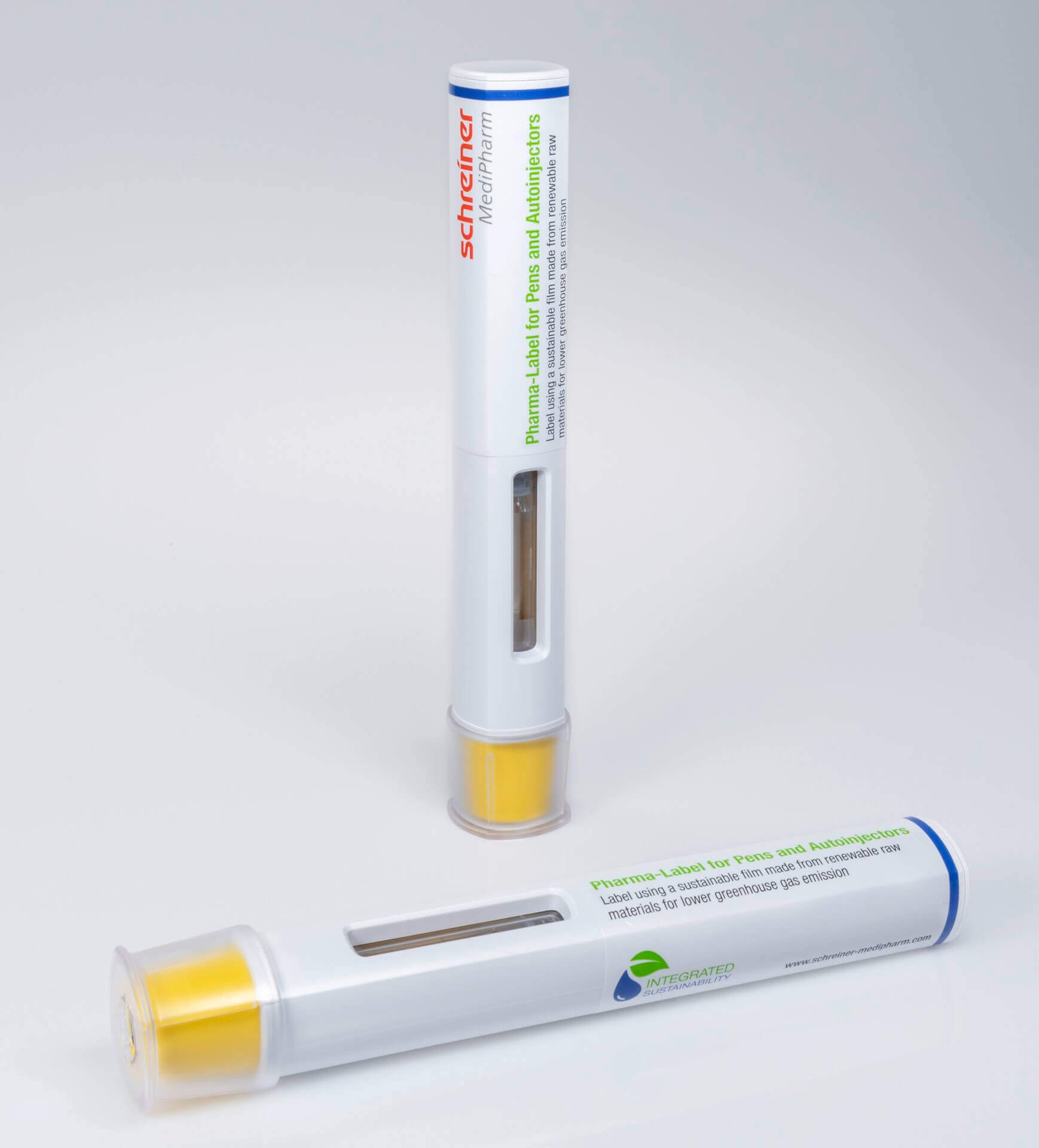

KK: Schreiner MediPharm has already developed concepts for sustainable functional labels, including an Autoinjector-Label made from eco-friendly film materials. The PFC was calculated for that purpose and we were able to show that CO2 reduction potential in the two-digit percentage range is possible.

Are there already any initial sustainable product developments by your company?

SG: The YpsoMate® Zero from Ypsomed is the world’s first CO2 emission-free prefilled autoinjector. The YpsoMate® autoinjector platform is being converted to biopolymers and the packaging design adapted in order to reduce emissions. The remaining emissions are compensated for by carbon removal certificates.

KK: Schreiner MediPharm has already developed concepts for sustainable functional labels, including an Autoinjector-Label made from eco-friendly film materials. The PFC was calculated for that purpose and we were able to show that CO2 reduction potential in the two-digit percentage range is possible.

What responses from the pharma industry do you receive in relation to A2Z?

SG: So far, all our customers have responded very positively and invited us to share our ideas. In addition, the alliance opens the door for us to other groups in the pharmaceutical industry such as PEG (Pharmaceutical Environmental Group), BioPhorum, EFPIA (European Federation of Pharmaceutical Industries and Associations), PSCI (Pharmaceutical Supply Chain Initiative), etc.

KK: We’re seeing major interest in the alliance and its goals on the part of our pharma customers as well. Our customers are setting themselves ambitious sustainability goals and are looking for partners within their supply chains that can proactively support them on their journey toward net-zero emissions.

Alliance to Zero

More information about Alliance to Zero at www.alliancetozero.com

* The interview was conducted in June 2023.