Speedy Service: Strong Parts Made by 3D Printers

SCHREINER SERVICES

Speedy Service:

Strong Parts

Made by 3D Printers

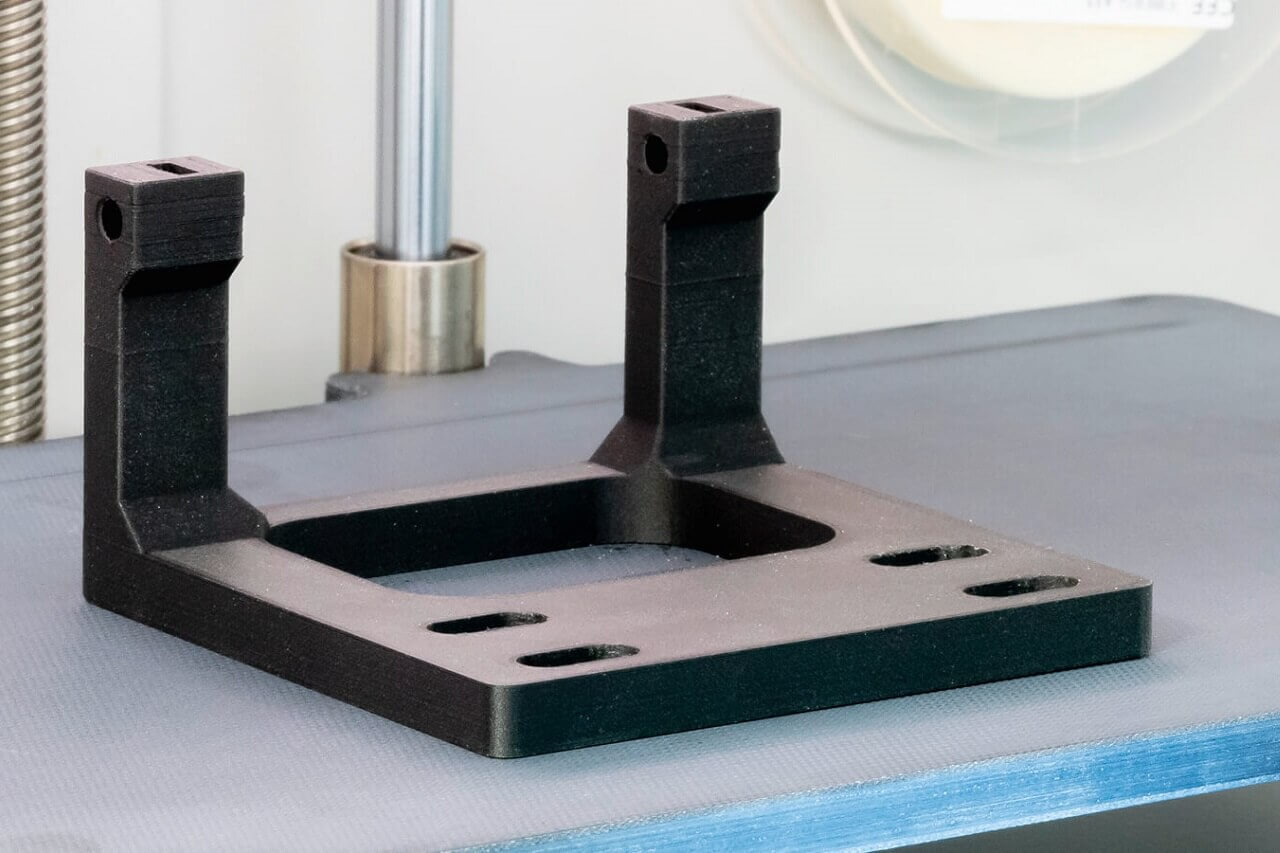

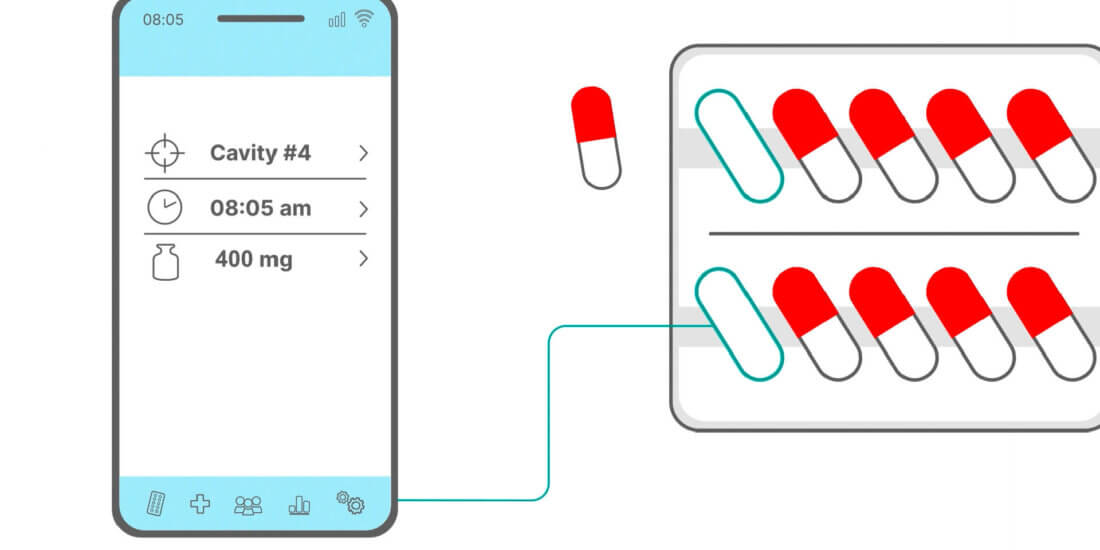

Many of us may still remember this from our childhood days: We’ve made something truly beautiful and creative from a collection of LEGO bricks and, just before we’re finished, we notice that one particular brick is missing. All the others are too big, too small or have the wrong shape. Users of special-purpose machinery are familiar with similar problems because such machines are always custom developments. Many of their components have to be individually modified and manufactured. This is often complex, time-consuming and nearly always costly. However, Schreiner Services has a simple and cost-effective solution not only for such requirements. Even subsequent component modifications and spare parts for older machines can be produced in rapid and robust ways: the necessary part is manufactured in a 3D printer and immediately delivered.

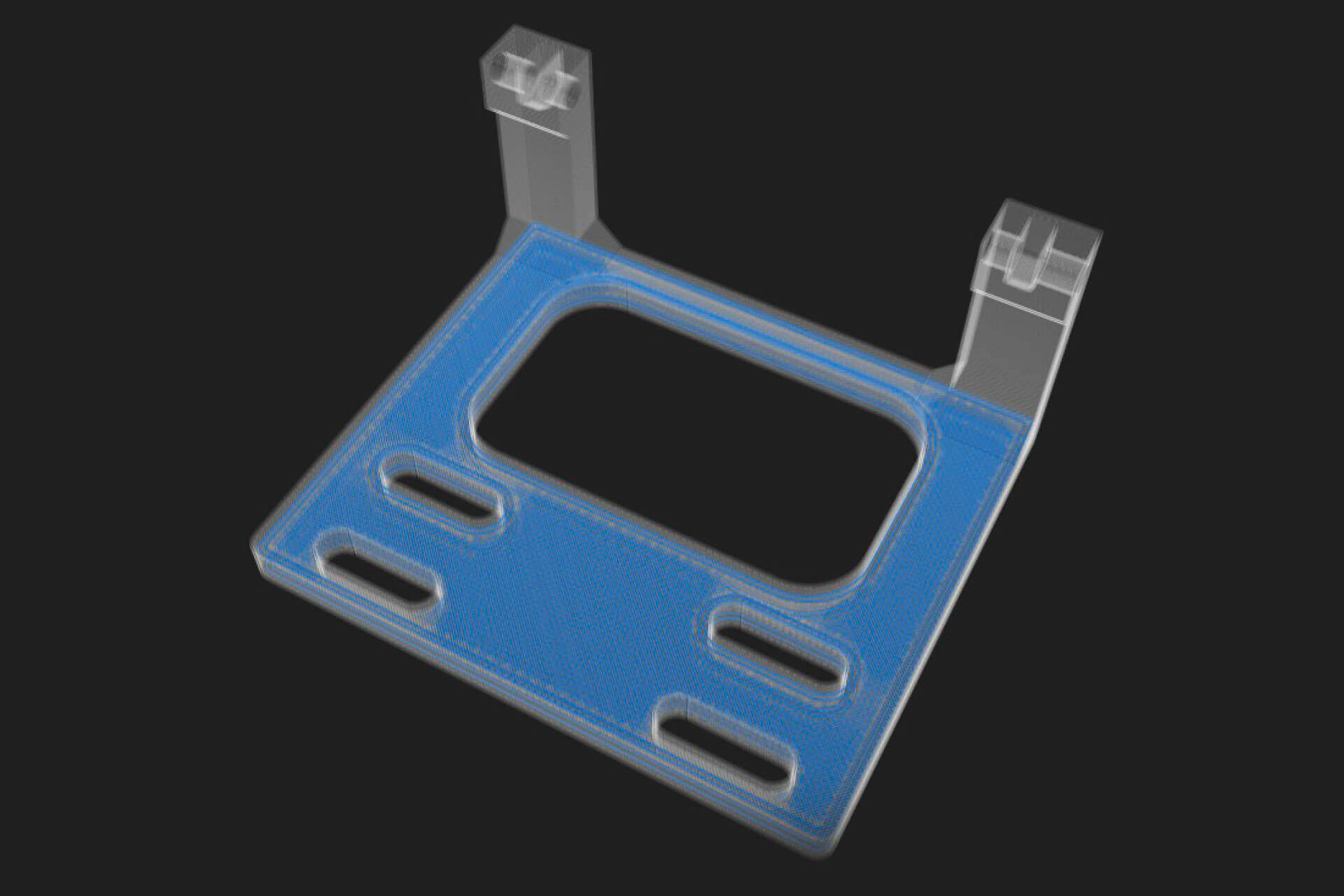

Special-purpose machines provide manufacturers with a competitive advantage because the products they produce are often unique. However, the large number of product-specific components often results in long lead times, both in the build stage and in cases of emergency when spare parts are needed quickly. Producing parts in a 3D printer is clearly faster. Three-dimensional, highly stable plastic components are 3D-printed in a matter of one or two days. The material to be printed can be reinforced with continuous glass, Kevlar or carbon fibers for additional stability.

3D Printers

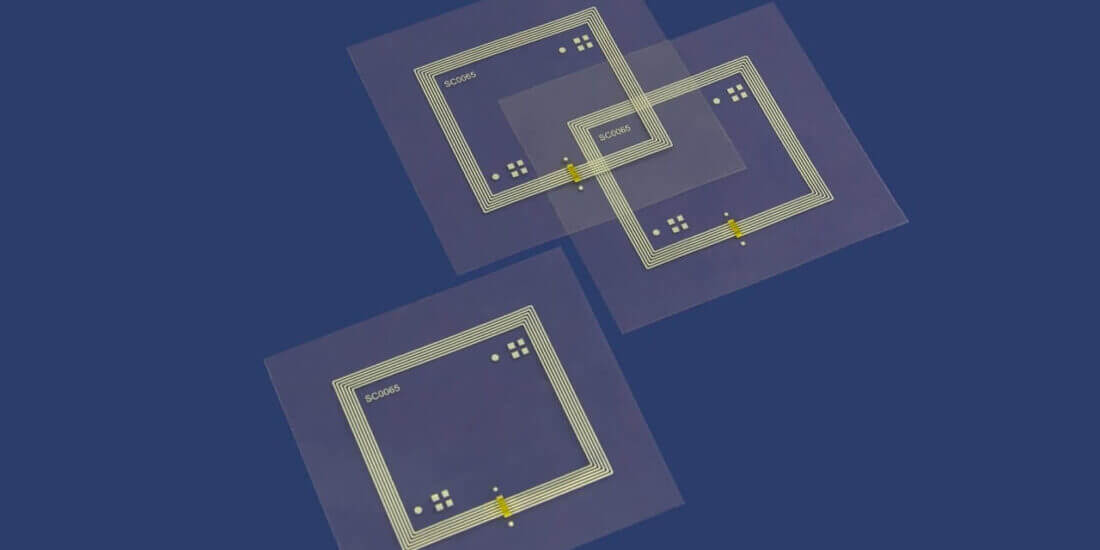

are machines that can produce three-dimensional parts based on digital data. The base materials can be plastics, wax, liquid epoxy resin, metal or ceramic powder and even chocolate, depending on the process. The material is applied to a platform in thin layers and cured. Chuck Hull is regarded as the inventor of 3D printing. In 1984, he filed the first patent claim for stereolithography— an additive manufacturing technology featuring the layered composition of an object.

From component fixtures, punches and pulleys to complex geometries, any desired shape can be produced at low costs, on short notice and at high levels of stability. Even subsequently desired component modifications on a machine can easily be designed and replaced. If a modification of the product itself is desired, it can be implemented quickly and at low costs by means of a new component fixture. The production of spare parts by means of 3D printers is particularly suitable for special-purpose machinery, complex components and older machines for which original parts are no longer available.