Semi-Automatic Dispensing System for Vial Labeling

SCHREINER SERVICES

Semi-Automatic Dispensing System

for Vial Labeling

Pharmaceutical manufacturers use fully automatic dispensing systems for fast and precise labeling of containers with liquid medicines. These systems are cost-efficient when large volumes have to be processed. But what if only a small number of pharmaceuticals require labeling? Manual labeling of vials is not only time-intensive and uneconomical but may also result in inconsistent application of labels. Schreiner Services has an ideal solution for the pharmaceutical customers of the Schreiner MediPharm business unit: a semi-automatic dispensing system that processes small series of diverse pharmaceutical vials at consistent levels of quality.

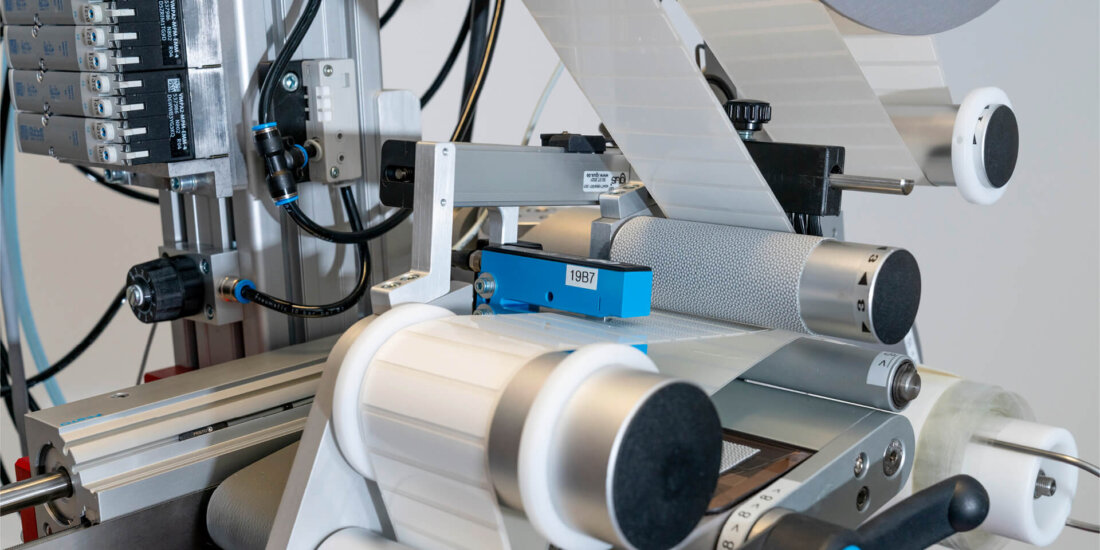

The dispensing device enables automated labeling of vials and infusion bottles. It can be adjusted to varying vial sizes, bottle shapes, and container diameters individually and flexibly. The settings of the system, which is easy to operate, can be changed quickly and without any effort for the next labeling job.

Mini vial or maxi bottle? The flexible dispensing system can label either.

Any glass container, from very small vials with narrow radii to large bottles, can be processed on the dispensing system. Container diameters from a minimum of 15 millimeters to a maximum of 170 millimeters are possible. The height of the bottles to be processed ranges between 35 and 250 millimeters, depending on their shape.

The semi-automatic label dispensing system is suitable for labeling pharmaceuticals in clinical research settings, for very small quantities, for handling special requirements, and for very expensive pharmaceutical products produced in small volumes.