Readable through the Painting Process

SCHREINER PROTECH

Readable through the Painting Process

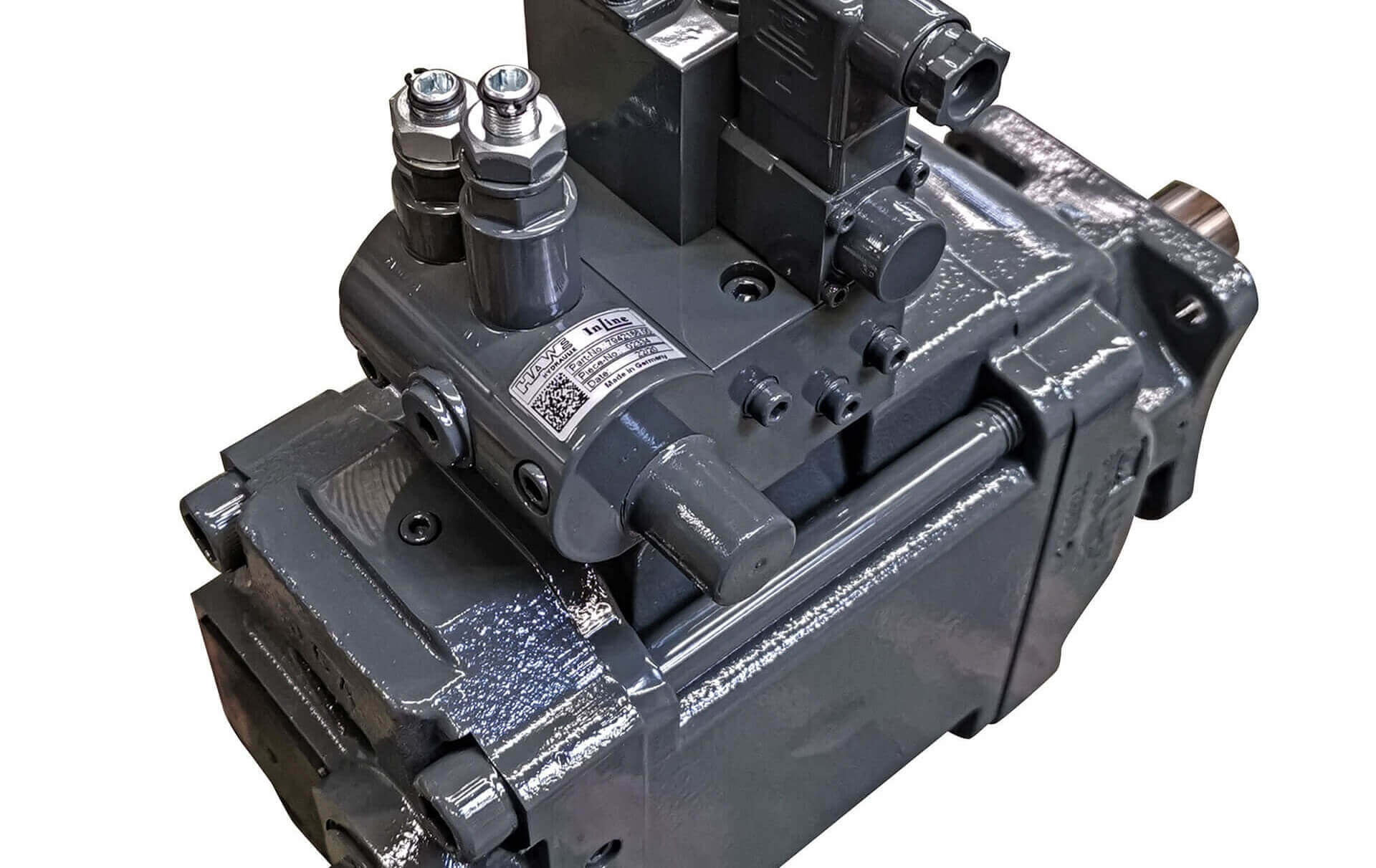

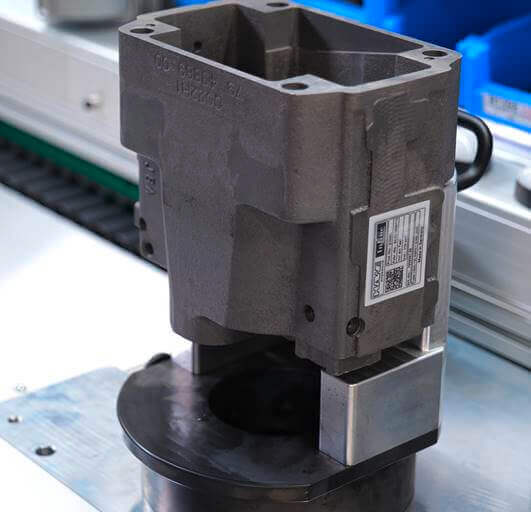

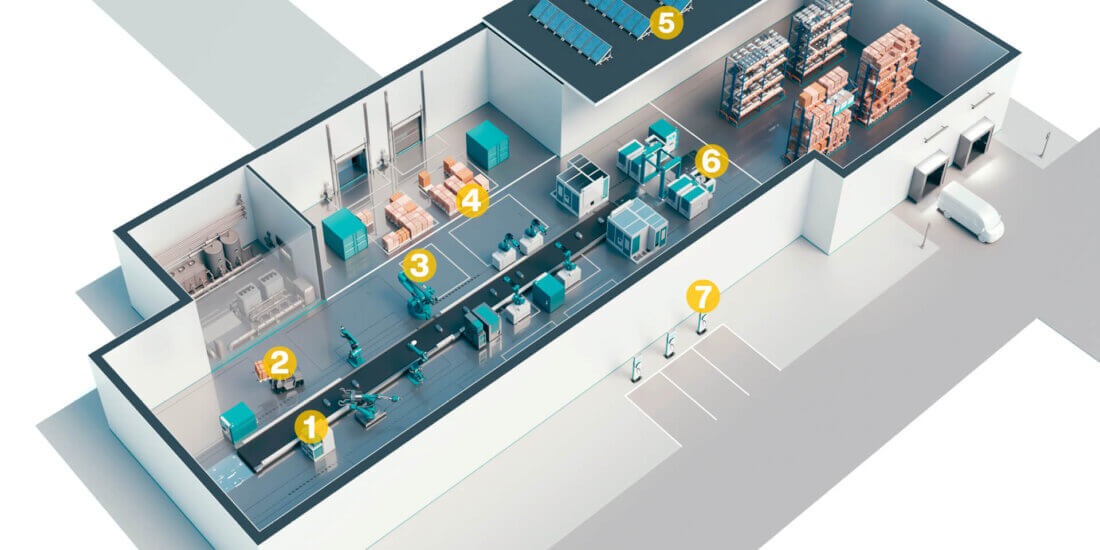

Whenever individually marked components are painted the inscription has to be protected against the paint in order to be readable again after the painting process. Schreiner ProTech’s portfolio includes a label with a paint mask attached to the marking label. Following the inscription of the 2D code, the folding paint mask is applied by means of its folding mechanism. The company InLine Hydraulik GmbH relies on exactly this solution for marking controllers and hydraulic pumps in the painting process.

In the past, InLine Hydraulik used metal nameplates to mark components at the end of the production process, which precluded automated integration of digital information and storage or tracing. Schreiner ProTech’s new hinged paint protection label is printed with a 2D code on site and manually applied to the pumps and controllers early in the manufacturing process. After painting, the paint mask is peeled off, which ensures readability. This new solution made it possible to introduce 2D code marking enabling inLine Hydraulik to optimize the manufacturing process and enhance its reliability. Now, automated traceability is ensured at any time.

Schreiner ProTech’s paint mask solution offers the additional option of combining a removable paint mask label with durable overlamination for permanent protection of the nameplate underneath against mechanical stress. After the drying process of the coats of paint, the protection label is peeled off using a starter tab. This ensures easy handling even when working with gloves. The paint mask itself is a little smaller than the marking label. As a result, the label will remain embedded in the paint after removal of the paint mask film and thus be permanently protected.