Practical and Space-Saving: Mini-Cap-Lock Secures Glass Syringe

SCHREINER MEDIPHARM

Practical and Space-Saving: Mini-Cap-Lock Secures Glass Syringe

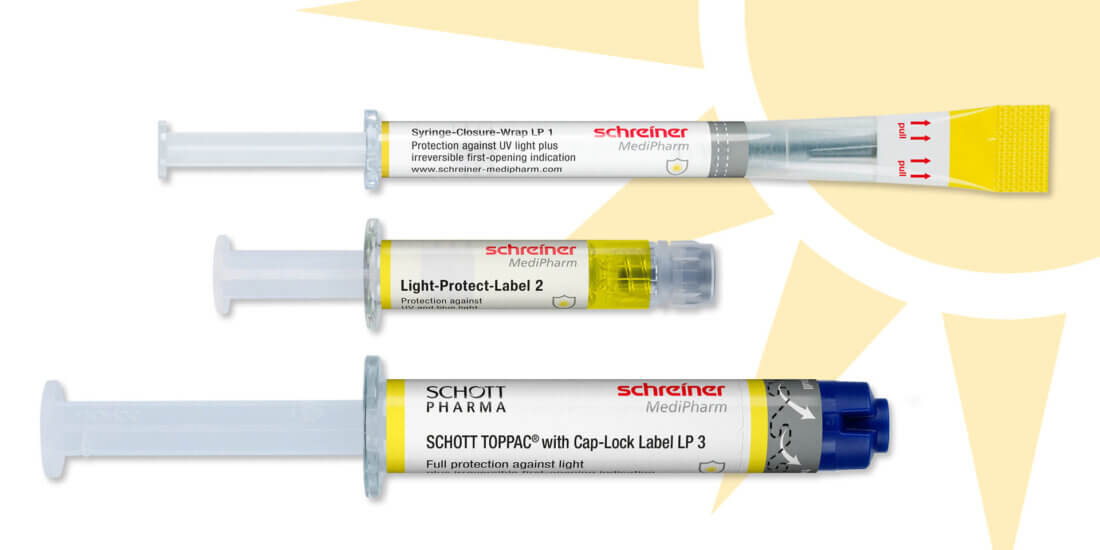

Cap-Lock, the innovative solution from Schreiner MediPharm for protecting the integrity of Luer Lock COC syringes, is now being adapted for use also on glass syringes. The novel “Mini-Cap-Lock” security concept is based on a small cap adapter that is applied to the upper part of the syringe cap to equalize the different radii of the syringe barrel and the upper part of the closure cap. Combined with a functional label that wraps around the syringe and the cap, this results in reliable first-opening indication with additional benefits.

Luer Lock is a standardized twist-lock system for syringes. For Luer Lock syringes made of COC material, Schreiner MediPharm already offers a special security concept: Cap-Lock. It features a specially designed plastic cap adapter that is applied to the primary closure of the syringe and interlocks with it to equalize the different diameters of the syringe barrel and closure, enabling the application of a label for sealing. First opening and tampering attempts can thus be reliably indicated.

Schreiner MediPharm’s Cap-Lock concept is now also intended for future use on Luer Lock glass syringes. Because the diameters of the syringe barrel and cap are very similar for most glass syringes an adapter that encloses the entire cap is not an option in this case. However, the caps of glass syringes are tapered toward the top and that’s the aspect of which Schreiner MediPharm’s new Mini-Cap-Lock takes advantage. A small adapter cap is attached precisely to the upper part of the syringe cap and serves as an adhesion area for fixing the label in place at the top. The label with an integrated perforation wraps around the cap adapter and the cap as well as the syringe barrel. When the cap closure is opened, the label is partially destroyed—thus clearly and irreversibly indicating the initial opening of the label.

The combination of cap adapter and label enables processing in the conventional pharmaceutical manufacturing process. Unlike shrink solutions, no heat is applied so that Mini-Cap-Lock is suitable also for syringes with sensitive substances. In addition, the label construction is a major benefit of Mini-Cap-Lock: On the one hand, the label serves as first-opening indication and on the other hand, the extended label area offers additional space for product information, color codes, and the integration of additional features such as anti-counterfeiting features, light protection, or an RFID chip. Among other things, the RFID functionality enables digital identification on unit level, for instance to optimize the supply chain in hospital settings or to avoid medication errors and can optionally be extended by digital first-opening indication.

In addition, it is possible to dispense with the blister pack when storing syringes with Mini-Cap-Lock in hospital settings because the special construction seals the syringe and ensures its integrity. That saves space and benefits the environment at the same time. With Mini-Cap-Lock, both the adapter and the label are customized to suit the specific application. The utilization of Mini-Cap-Lock by healthcare staff is easy and safe. Whether the medicine has previously been opened or possibly tampered with can be detected at first glance. Furthermore, thanks to the firm connection of the cap adapter and primary closure, the syringe can be opened as usual with just one flick of the wrist. Patient protection and ease of use thus go hand in hand.