PCS in Nameplates: Marking and Venting Combined

SCHREINER PROTECH

PCS in Nameplates:

Marking and Venting Combined

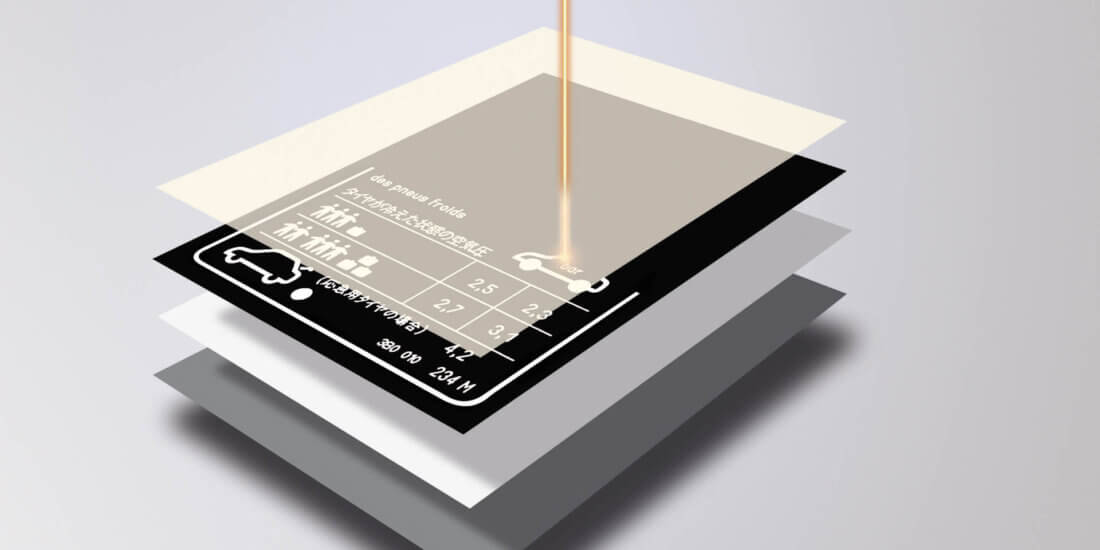

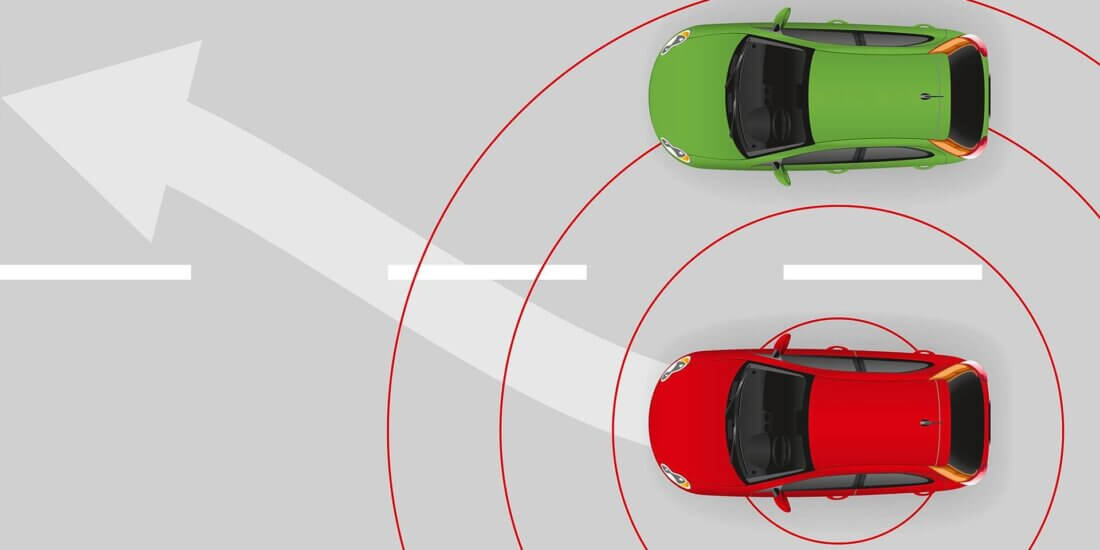

Smart sensors have become indispensable to modern industrial transportation systems: The RFID devices from SICK ensure a seamless identification solution in line with Industry 4.0 throughout the entire value creation process. Complete transparency and planning certainty will play an increasingly important role for companies in the future. SICK produces these sensors that have to resist numerous environmental influences such as major temperature fluctuations and the effects of moisture in target applications. To vent such housings while maintaining ingress protection according to their IP code and to mark them, Schreiner ProTech has developed a nameplate that is provided with a pressure compensation seal (PCS).

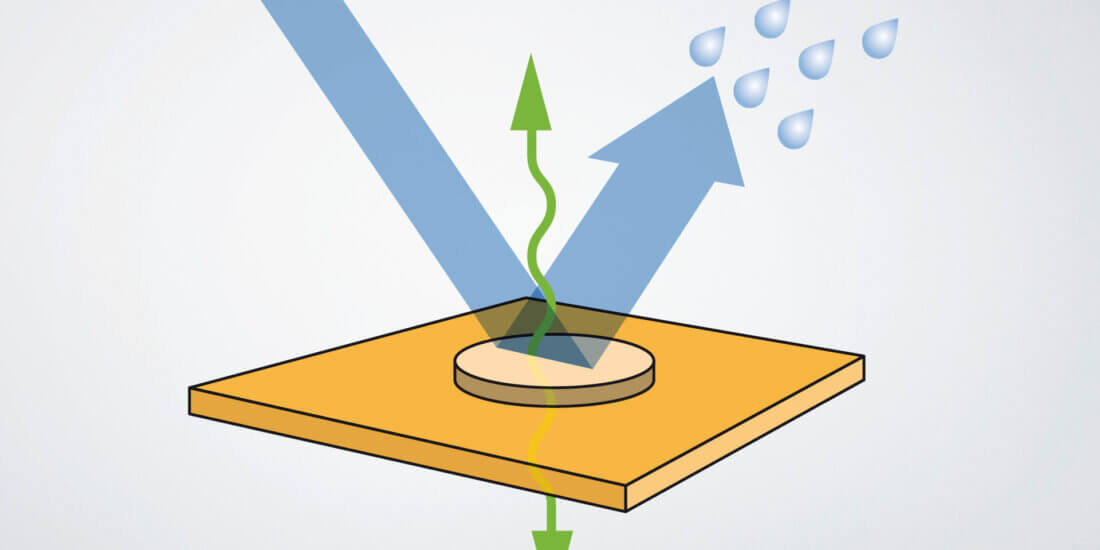

Temperature fluctuations may result in excess pressure or vacuum in electronic housings. Pressure differences stress the assembly components and their individual elements and may cause damage resulting in the destruction of the electronic system. A pressure compensation seal regulates this pressure by

means of its membrane and at the same time provides protection against external influences such as water or dust. In many cases, housings require both protection and marking. However,several products and process steps slow down the production process and increase the rate of defects.

SICK AG is a manufacturer of sensors for factory, logistics and process automation with worldwide activities. For the sensor housing of a driverless transport system (FTF), SICK was seeking a solution for venting and marking, and opted for a pressure compensation seal from Schreiner ProTech. “The processing of the pressure compensation seal and nameplate in a single pass saves process times and thus significantly cuts process costs. In addition, the solution saves a lot of space because marking and venting elements do not have to be installed side by side. Scanning the 2D code in the final process step also ensures that the membrane was installed as well,” says Gordon Bickel, development engineer at SICK.

Saves time and costs in the production process: nameplate with venting function

Additional Benefits

- The application of a single product to a housing reduces qualification requirements.

- Customized inscriptions are performed at the customer’s site.

- The label size is adapted to the customer’s requirements.

System Expertise

Membranes are high-tech products requiring professional processing for proper performance. To ensure their reliable application to components, Schreiner ProTech offers an application system that is optimally adapted to self-adhesive PCS.