Needle-Trap: Less Material, More Efficiency

SCHREINER MEDIPHARM

Needle-Trap: Less Material, More Efficiency

Safety for the user, cost efficiency for the manufacturer, and a clear gain for the environment: With Needle-Trap, Schreiner MediPharm offers a unique system for protection against needlestick injuries combining economy and sustainability in a single product—while setting standards.

Unlike conventional systems, the needle protection of Schreiner MediPharm’s Needle-Trap is not an additional device but an integral component of the label. Delivered on rolls, it can be applied to syringes on dispensing systems at high speed and without additional process steps. For pharmaceutical manufacturers, that means less logistical effort, less material, less costs.

But Needle-Trap impresses not only in terms of processing and process optimization. Regarding sustainability, the system shows its strengths as well: Compact design, no need for metallic springs, and clearly reduced plastics content have effects along the entire supply chain—from reduced space requirements during storage, transportation, and cooling to more eco-friendly disposal.

The newest version, Needle-Trap Secu, even takes these benefits a step further. It enables blister-free packaging thanks to an integrated first-opening indication—as another contribution to the reduction of packaging materials, CO₂ emissions, and costs.

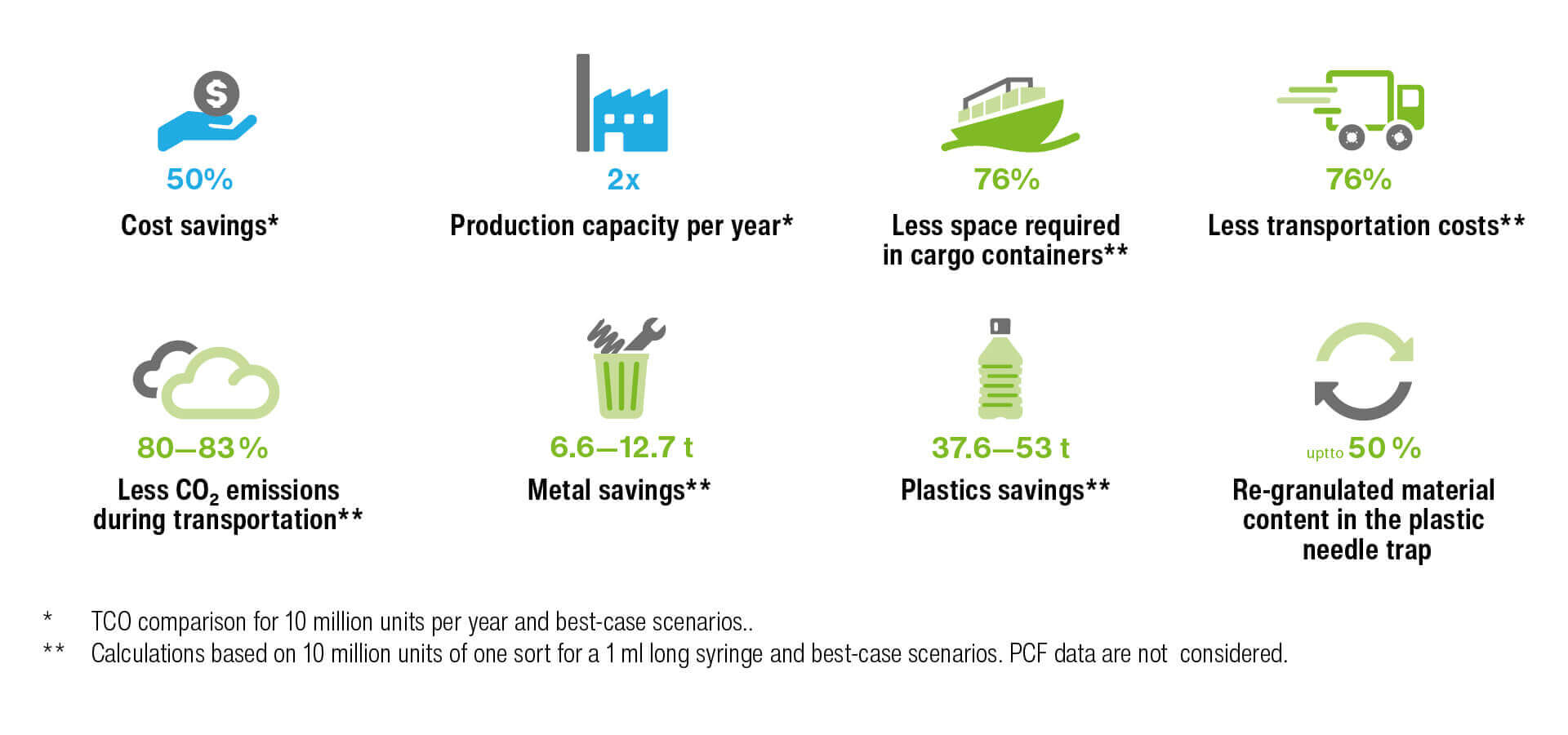

Calculation examples for 10 million units of Needle-Trap in terms of total cost of ownership and sustainability show: double production capacity per year, up to 50% less costs, more than 80% less CO₂ emissions, and reductions of up to 53 tons of plastics—all without compromising safety.

In other words, it’s a system that demonstrates that progress is created where smart solutions solve several challenges at the same time—to the satisfaction of customers and users, and benefit to the environment.

Needle-Trap Statistics

Compared to conventional needle protection systems, Needle-Trap offers pharmaceutical manufacturers decisive benefits in terms of cost efficiency (TCO) and sustainability thanks to easy integration into their production processes and its compact design.