Invisible but so Important: Protection Films Serving the Automotive Industry

SCHREINER PROTECH

Invisible but so Important: Protection Films Serving the Automotive Industry

In the fast-paced world of the automotive industry a frequently overlooked component makes a crucial contribution to the quality and safety of modern automobiles: protection and specialty films. Rather inconspicuous at first glance, these solutions from Schreiner ProTech help to actively shape the future in the automotive market.

The trend in automotive cockpits is clearly discernible.

Increasingly larger and more powerful displays are gaining traction. That results in a growing need to protect them against external influences. Especially in the age of pillar-to-pillar displays extending across the entire width of the vehicle, specialty protection films and adhesive solutions have become indispensable. Display protection films ensure the quality of displays until the vehicle is handed over to the customer by protecting them against mechanical damage. The films can also be designed for optimal ESD performance so that applying or peeling off the protection film does not result in electrostatic discharge damaging electric components.

Safety first

With increasing electrification of the automotive sector in-vehicle electronics are becoming more and more sensitive while on-board voltage levels continue to rise. Insulation films play a key role in ensuring the safety and reliability of in-vehicle electronics. All of Schreiner Group’s specialty films have high dielectric strength which is crucial for trouble-free performance of on-board electronics and avoidance of safety risks.

Clever Multifunctional Components

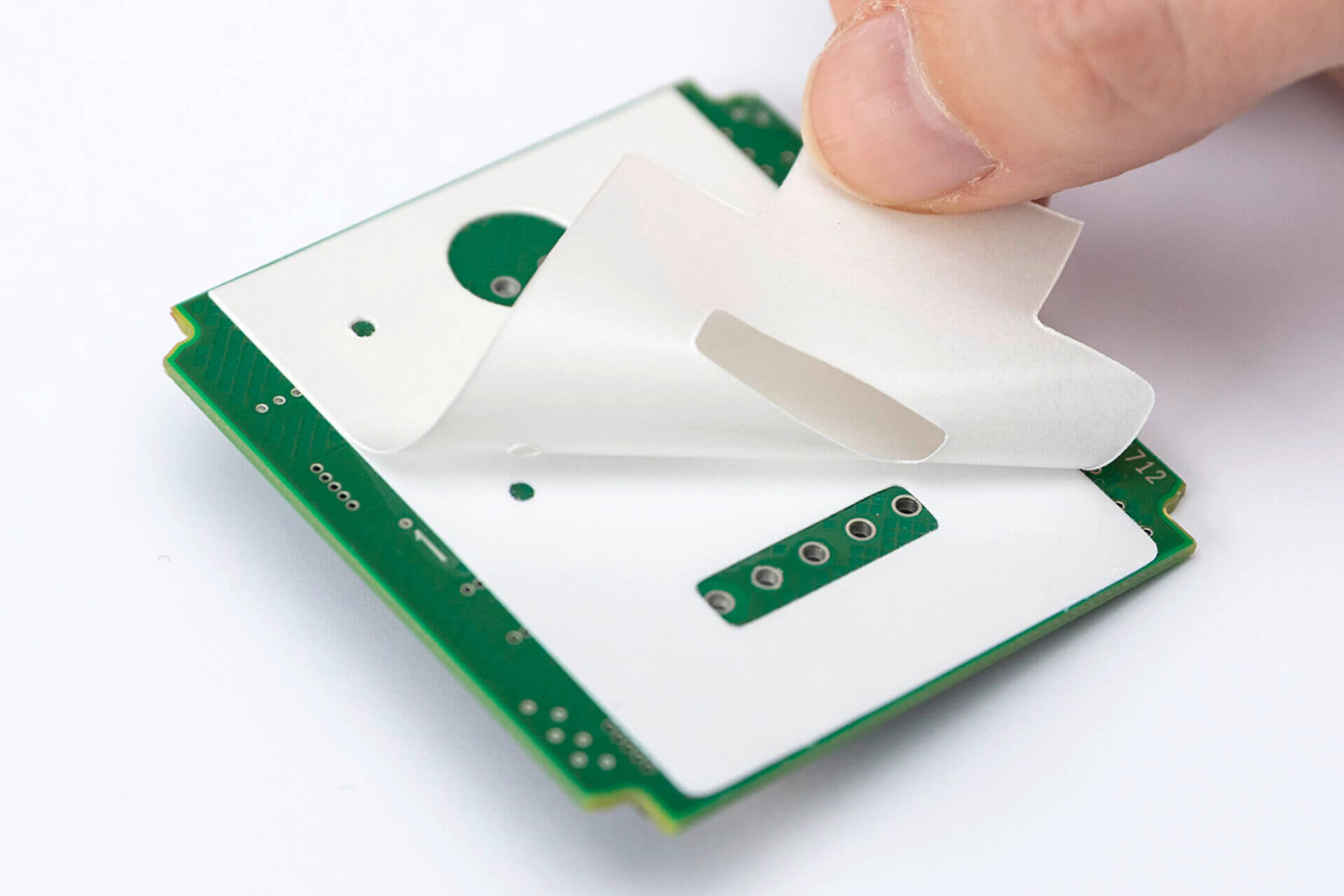

In addition to insulation films, self-adhesive diecut parts are true multi-talents because these multifunctional adhesive solutions can be used for insulation purposes as well. An intermediate film layer between the printed circuit board (PCB) and the housing, for instance, can have an insulating effect while the various adhesives can be adapted to the specific requirements of the surfaces. This not only secures the bond but also protects components against dielectric breakdown and the resulting potential failure of electronic systems.

A Product with Potential

When it comes to using protection and specialty films in the automotive sector, there are three aspects taking center stage: protecting, joining, and insulating.

Whether displays etc. require protection against scratches and impacts, the performance of electrical components must be ensured, or further innovative applications need to be developed: there’s massive potential to be tapped in the field of protection and specialty films. For the automotive industry, these versatile components have already become indispensable. Other industries depending on powerful adhesive bonding and protected displays have recognized their possible uses as well. Exactly that is what drives Schreiner Group’s experts. They’re currently working on particularly sustainable protection films while the team at Schreiner ProTech keeps pursuing new ideas to fully tap the related potential in order to actively help shape the future in this area.