Industry 4.0 “We still have a long way to go.”

SCHREINER PROTECH

Industry 4.0 “We still have a long way to go.”

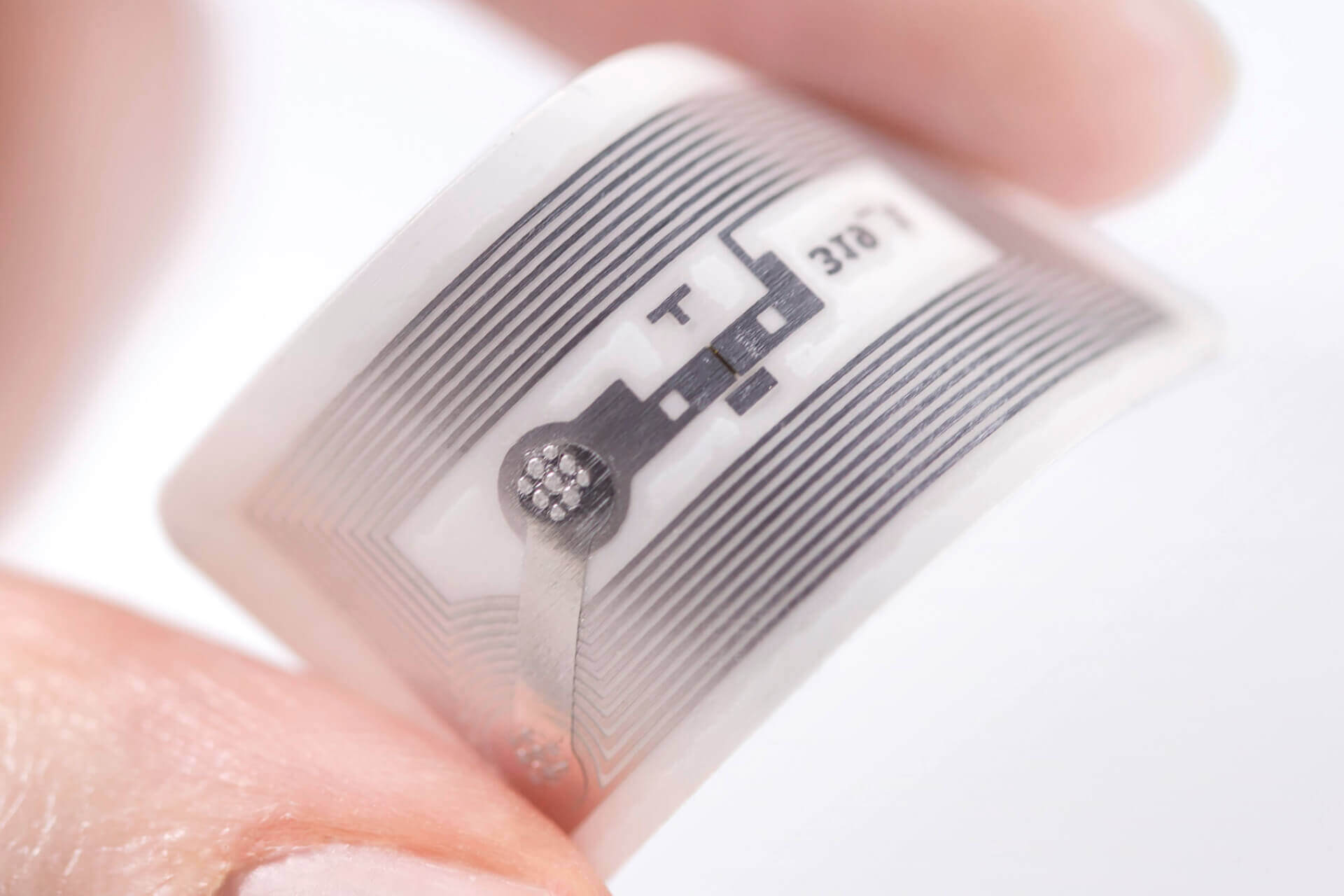

Connected, intelligent, and flexible—that’s the plan for the new world of work. Thanks to IoT and RFID that vision has already become a reality in many areas. But where exactly are we on the road toward Industry 4.0? Futurist and science journalist Dr. Ulrich Eberl explains how even smallest high-tech labels and smart RFID tags can make a major contribution to this development.

Dr. Eberl, the catchword “Industry 4.0” has been around for more than a decade. Honestly, how digital is German industry really, today?

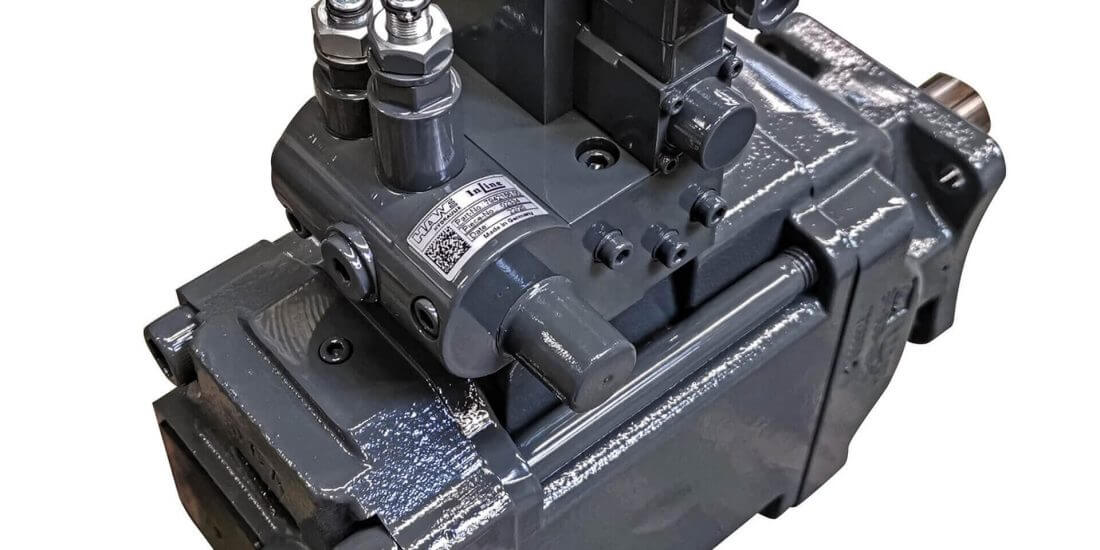

The German term “Industry 4.0” is an international success story. It is known around the world, not only in Europe but also in China, Japan, South Korea, and the United States. In essence, it’s about highly automated and flexible manufacturing. At least in terms of digitalization, at lot has already happened in Germany, in large companies as well as in SMEs. The coronavirus pandemic has provided another boost. It’s amazing how many people are able to work from home pretty effectively today. But we still have a long way to go. Seamless transitions between software solutions are by no means the current state of the art and the comprehensive Internet of Things—with endto- end machine-machine and machine-machine-object communication—is still a vision in many cases. However, with 5G mobile telecommunications, sensor systems, RFID technology, and high-tech labels like those that Schreiner Group produces that, too, will become a reality.

In view of automation and AI: How likely is it that only high-tech robots are going to do our jobs in the near future?

Artificial intelligence already determines our everyday lives more than a lot of people realize. Take smartphones for example: unlocking by facial recognition, image searches, voice assistants, translation programs, health apps—all that is based on AI, just like the collaborative robots that work hand in hand with humans on the factory floor. Yet even the most complex AI systems are based merely on mathematical optimizations. A machine cannot be expected to have common sense. Smart machines are going to handle routine tasks, on the factory floor as well as at the office, but humans are indispensable wherever flexibility, creativity, and problem-solving thinking are needed. In research, design, planning, and quality assurance as well as in communicating with customers and partners.

In your current book “Unsere Überlebensformel” (Our Survival Formula) you address the major global environmental crises. How can they be solved?

Above all, we need to wean ourselves from our carbon energy drink, as I call it. We need to generate energy without coal, be mobile without oil, heat without natural gas, build without concrete, operate without waste, think in terms of circular systems, and eat more sustainable food; in a nutshell: we need to live with rather than against nature. The good news is that we already know most of the solutions and they can be put into action in economically feasible ways. For instance, wind and solar power is cheaper today than power from coal. In some regions, even by a factor of ten. By 2030, green hydrogen will be cheaper than hydrogen from natural gas and electric mobility is about to make its breakthrough as well, particularly because battery costs have dropped by 90 percent since 2010. Besides that, hidden champions like Schreiner are indispensable in this regard as well because they contribute key components such as pressure compensation seals or film heaters for advanced driver assistance systems.

Looking at the future—what lies ahead? What do companies have to brace themselves for?

In this and the next decade, the global economy needs to be transformed, literally in all sectors. That entails massive challenges as well as major opportunities. AI and robotics are going to play a key role in all companies, just like automated analysis and optimization of processes, and so-called resilient digital twins that quickly detect disruptions on the factory floor and in supply chains and help correct them. Companies will not be able to rest on “Industry 4.0”: “Industry 5.0” is already in sight.

Dr. Ulrich Eberl

is one of the most renowned German-language science and technology journalists. He earned his PhD in biophysics at TU Munich, worked for Daimler, and led communications about research, innovations, and future trends at Siemens for 20 years. Today, he works as a freelance futurist, speaker, and book author covering topics such as artificial intelligence (“Smarte Maschinen”) and solutions for the major environmental crises (“Unsere Überlebensformel”).