Hospital 4.0: Smart Labels for Medical Devices

SCHREINER MEDIPHARM

Hospital 4.0:

Smart Labels for Medical Devices

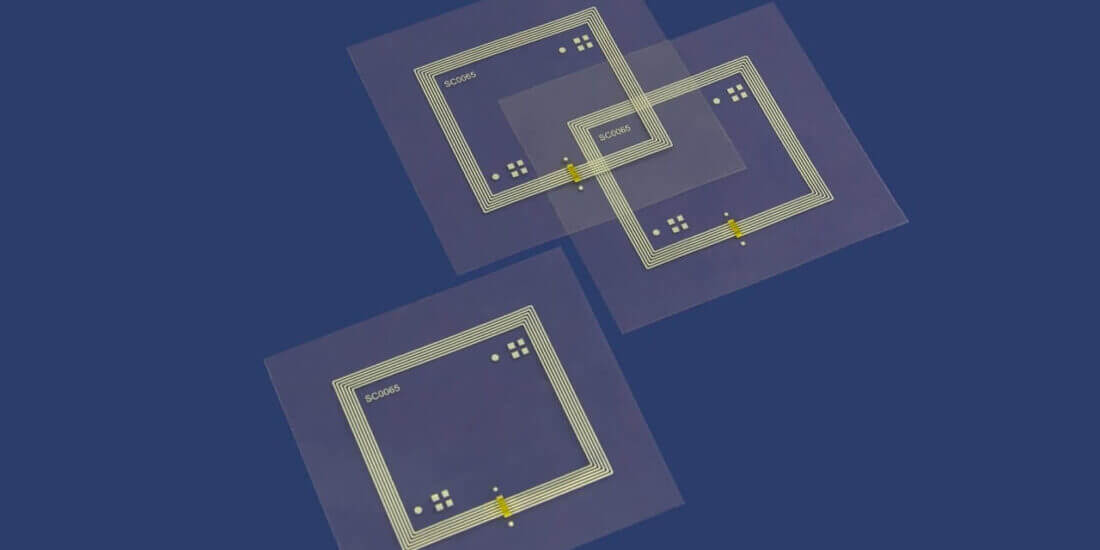

E-health and electronic applications are becoming more and more important in healthcare. Hospitals in particular increasingly require digital solutions to compensate for the growing number of inpatient admissions in the face of professional healthcare staff shortages. RFID and NFC are regarded as forward-thinking technologies when it comes to optimizing processes and products in the area of medical device technology. There are two fields of application offering particular potential here: “device or consumable authentication” for identification of consumable materials and medical equipment and “asset management” for enhanced monitoring of devices in hospital settings. RFID/NFC labels can make a key contribution in this context. Schreiner MediPharm has developed specialty RFID-Labels for product authentication and asset management. They help simplify workflows while enhancing patient safety.

Automatic Identification and Authentication of Consumables

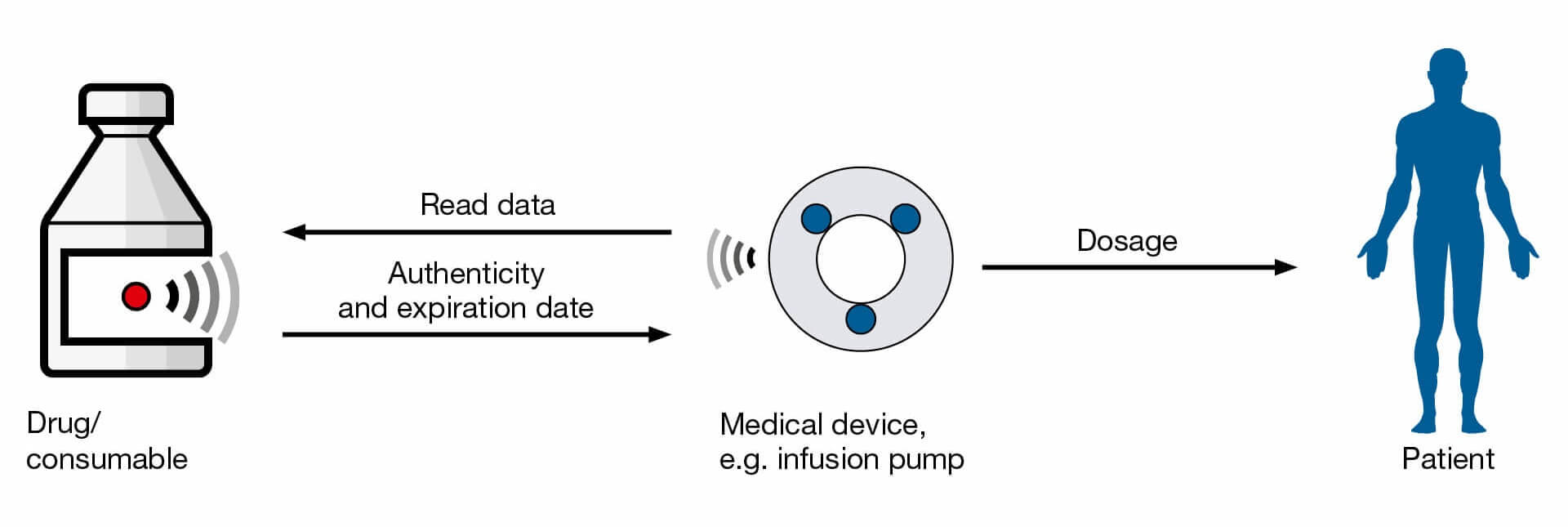

Consumable authentication focuses on the question of how to ensure that the right consumable materials are used for a specific application or for the respective medical equipment. The answer is based on the lock-and-key principle. Consumables are provided with an RFID tag and automatically read in a contactless process while being inserted in the equipment. As a result, original and therefore safe consumables such as filters and tubes, surgical materials as well as reagents or patient samples in diagnostic equipment can be authenticated, or different consumables in the same container can be distinguished from one another automatically. Information such as authenticity, expiration date, and LOT-specific data is stored on the chip, transferred to the equipment, and checked. In addition, usage cycles or residual quantities can be tracked and improper reuse be prevented. Furthermore, it is possible to monitor and secure multi-step processes.

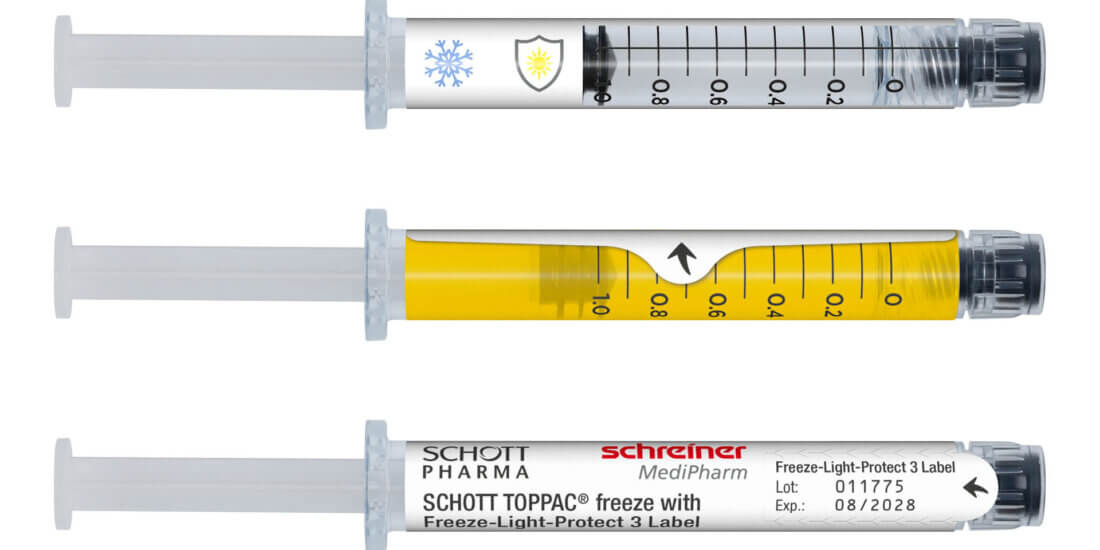

There is a wide variety of possible applications for RFID-Labels in this area. They can be utilized in injection devices, pens and autoinjectors, laboratory equipment, and diagnostic devices. For each use case, a customized, particularly robust label design is developed to support the various objectives:

- Prevent use of expired, wrong, or falsified medicines and consumables

- Avoid application and dosing errors

- Stop illegal reuse and misuse of original containers

- Enhance patient safety during drug administration and self-medication

The costs for the hardware required in a medical device are relatively low—however, to ensure successful integration, it is important to implement the RFID tag for the consumables on the equipment together with the reading unit. Ideally, the RFID tag is directly integrated into the marking label.

Automatic Inventory and Asset Management

Asset management addresses the question of how to enhance monitoring of devices, for instance in hospitals, in order to keep a closer eye on potential malfunctions, usage, or maintenance. Here the solution lies in RFID technology as well. Ventilators, syringe pumps, and other critical devices are provided with RFID-Labels and rooms or areas are equipped with corresponding readers. The equipment is localized in real time by the readers through automatic data acquisition and tracking.

By storing maintenance intervals and additional information on the chip, equipment availability and impeccable condition can be ensured. As a result, healthcare staff can locate ready-to-use equipment that has been allocated to a regular location with greater ease and efficiency. At the same time, conclusions about usage patterns can be drawn, for instance of how frequently an infusion stand has been moved and used, from which necessary sterilization intervals can be derived.

The smart RFID solution for real-time localization is utilized not only in warehouse and inventory management of medical equipment but also increasingly for consumables. It supports objectives such as

- Capture product data automatically

- Optimize utilization of consumables

- Enhance process transparency and process reliability

- Enhance supply security

RFID technology should be integrated into the product label from the beginning in this solution as well. This can avoid subsequent and additional manual processes—such as the need for applying the RFID tag to the product only at the hospital.