Hello, Servo!

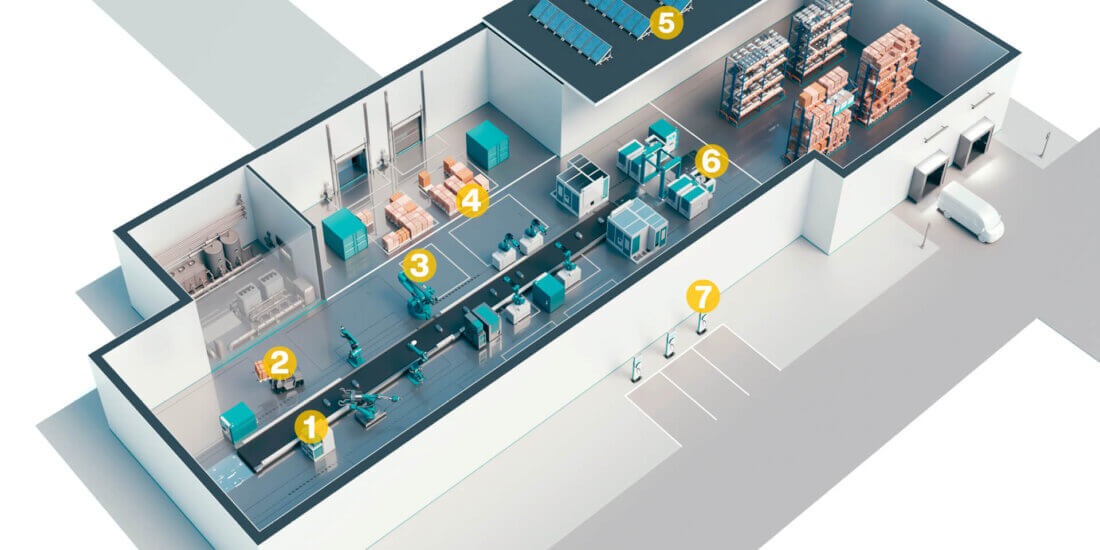

SCHREINER SERVICES

Hello, Servo!

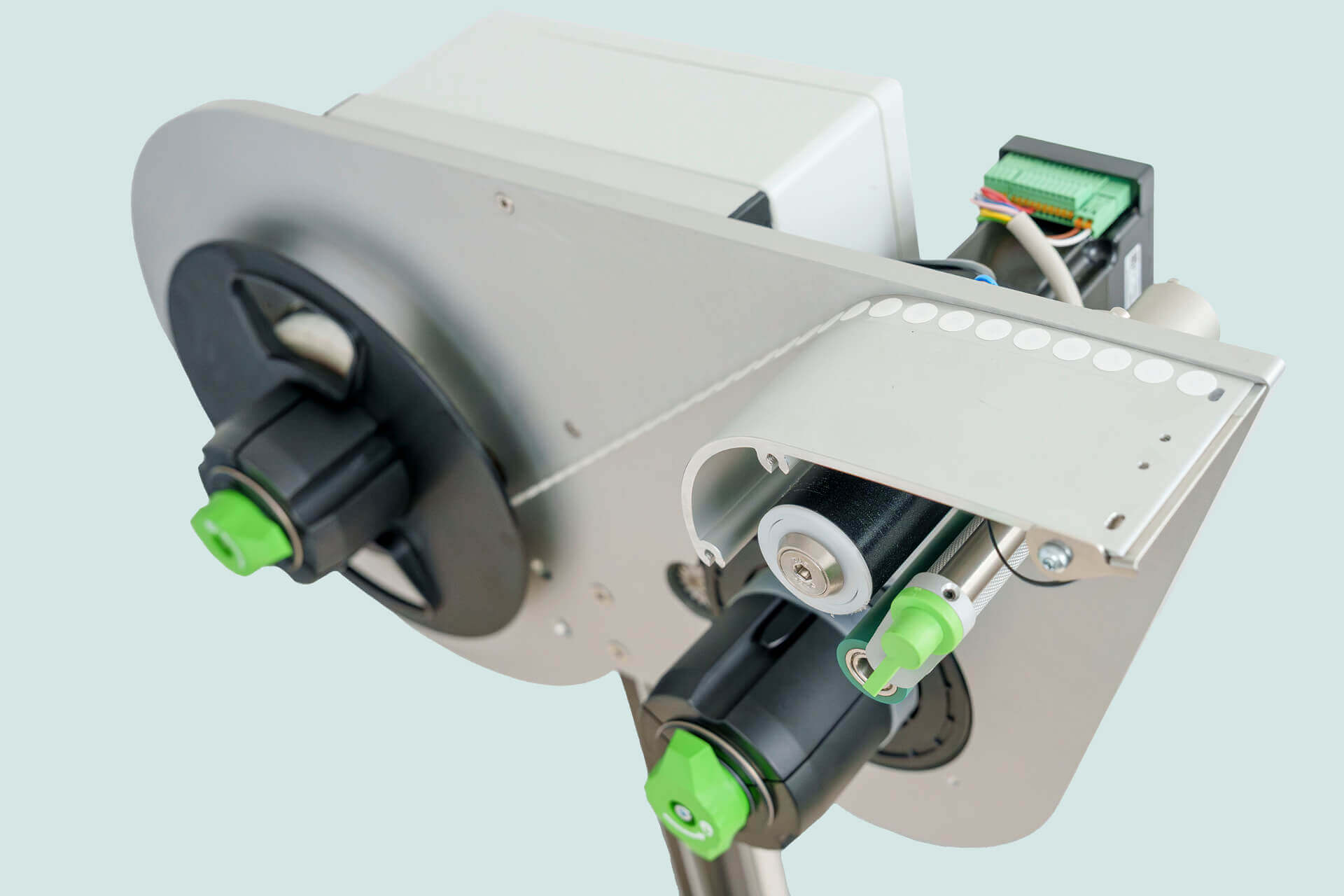

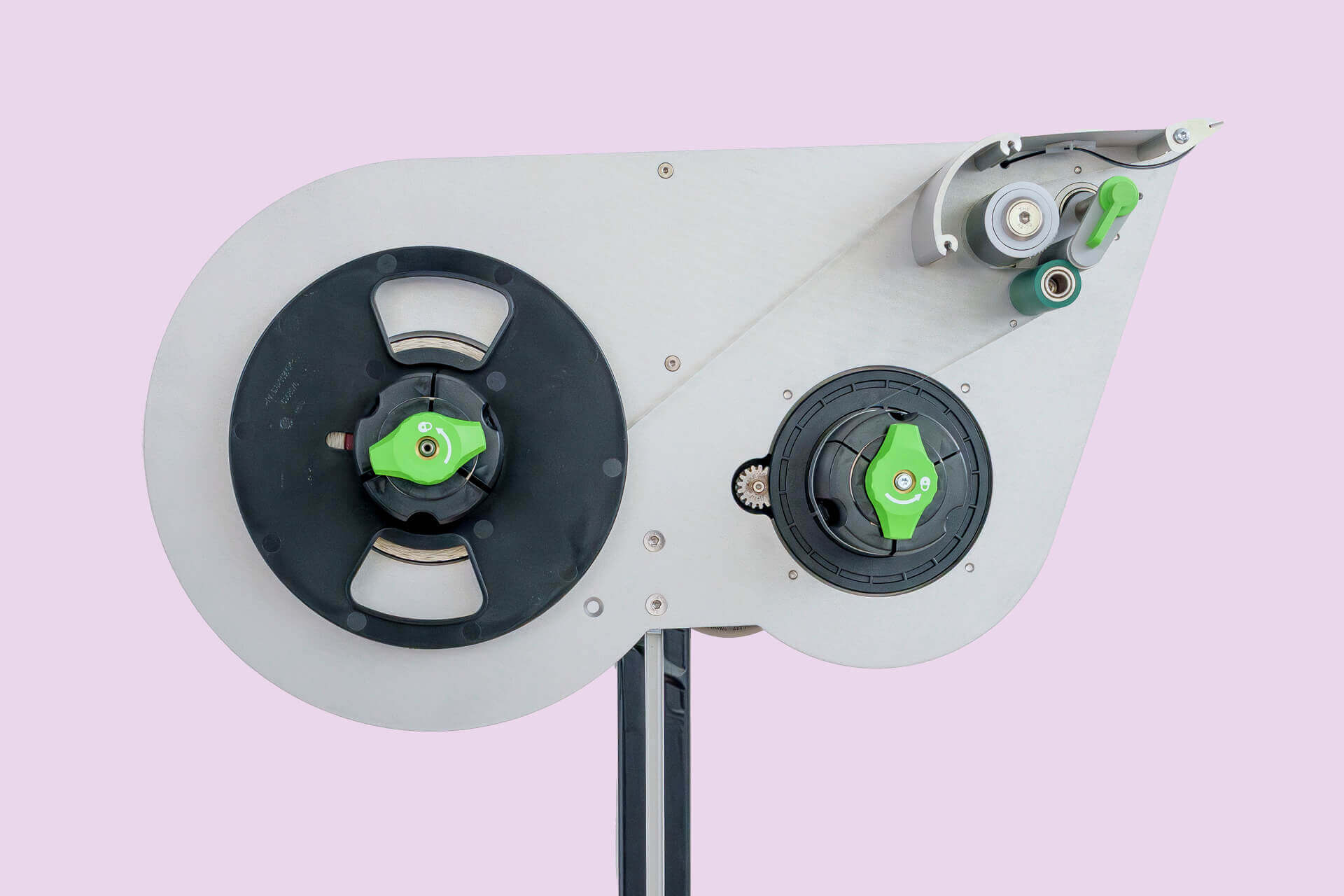

Labels with RFID chips, stiff, thick materials, or sensitive functional layers make high demands on the dispensing process. However, classic labeling/processing systems can damage sensitive materials and RFID chips due to multiple deflections around small rollers. That’s where a new dispensing system with a servo drive from the Schreiner Services competence center comes into play.

The key lies in the web tension: In industrial settings, labels are typically delivered on rolls and must be peeled off the liner for the application. To do so, the label web is mechanically tensioned by slowing down the speed of the material roll and pulling the liner across a dispensing edge. To achieve a uniform web tension, three so-called dancers and several pulleys are used, but the heavy bending around the pulleys can damage a RFID chip or PCS.

Easy Does It

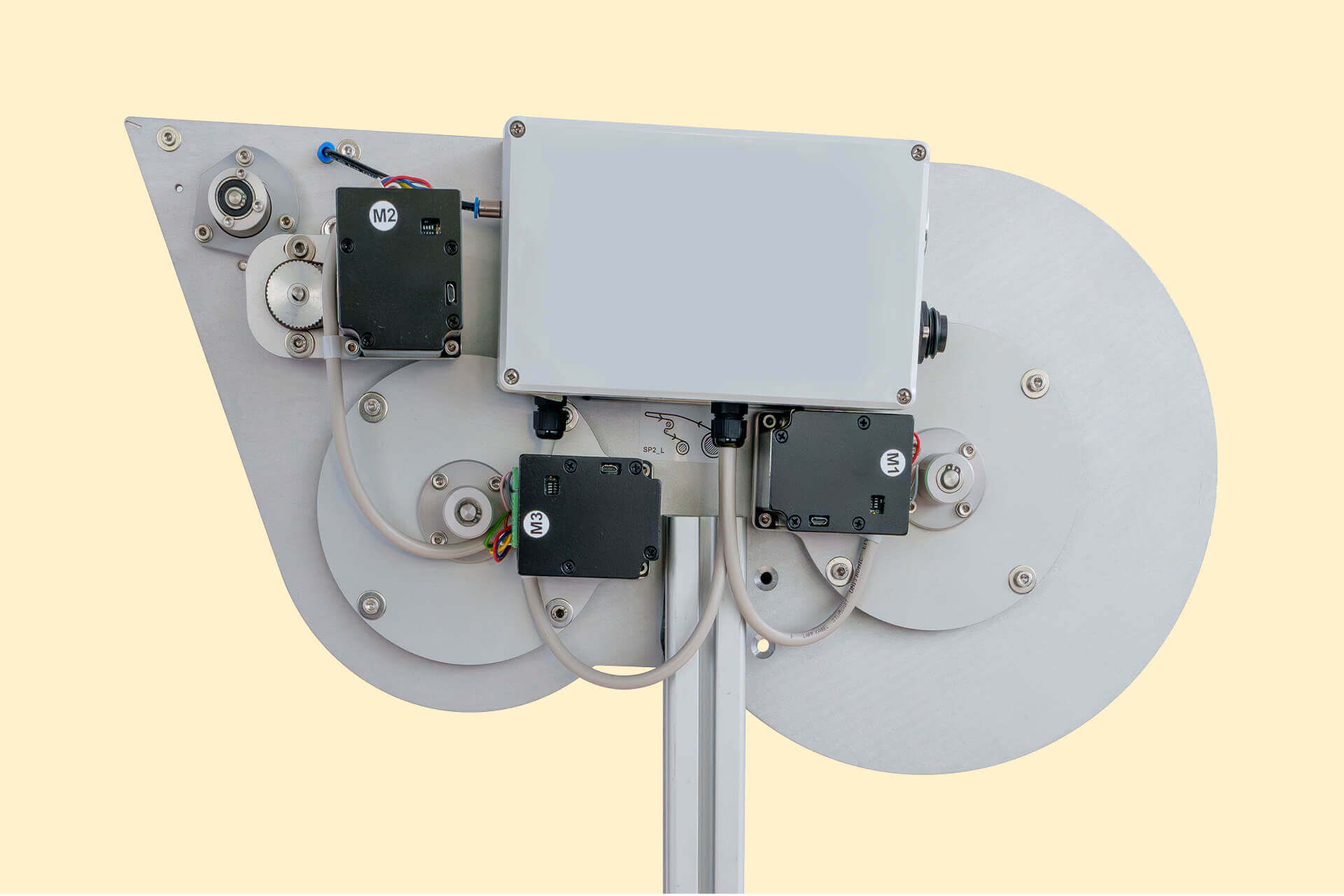

The newly developed dispensing system eliminates the need for pulleys. The label web is transported from the material roll directly to the dispensing edge and the surface of the label is not touched. “Instead, the web tension required for the dispensing process is generated via individually controllable servo motors enabling labeling in a reliable process—especially for sophisticated labels,” explains Michael Reineke, Head of the Schreiner Services competence center. That eliminates the risk of bending. In that way, servo-driven dispensing systems create new opportunities to reliably integrate complex functional labels in a stable process even for increasingly challenging designs.

The term “servo” comes from the Latin verb servire (“to serve”) and its first-person singular form servo, meaning “I serve.” In technology, it describes automatically controlled drives or systems that precisely respond to commands. In this case, the servo drive ensures the correct web tension.