From a Startup Idea to Mass Production

SCHREINER PRINTRONICS

From a Startup Idea to Mass Production

The high level of technology expertise available at the Schreiner PrinTronics competence center decisively contributed to Schreiner Group winning the Innovation Award Bavaria at the end of 2022. Over the past five years, the professionals in the field of printed electronics managed to develop a brilliant startup idea to the level of mass production.

But let’s start from the beginning. Eight years ago, Coldplasmatech, an innovative startup company, emerged as a spinoff from the Leibnitz Institute for Plasma Science and Technology INP. “Driven by our passion to make it possible for patients to enjoy a new sense of life we invented a new effective wound therapy and had it patented. Our specialists developed CPT®patch, an active dressing that effectively treats wounds,” says CEO Dr. Carsten Mahrenholz. Coldplasmatech is the world’s first company to use patented “Active Glow Technology®.”

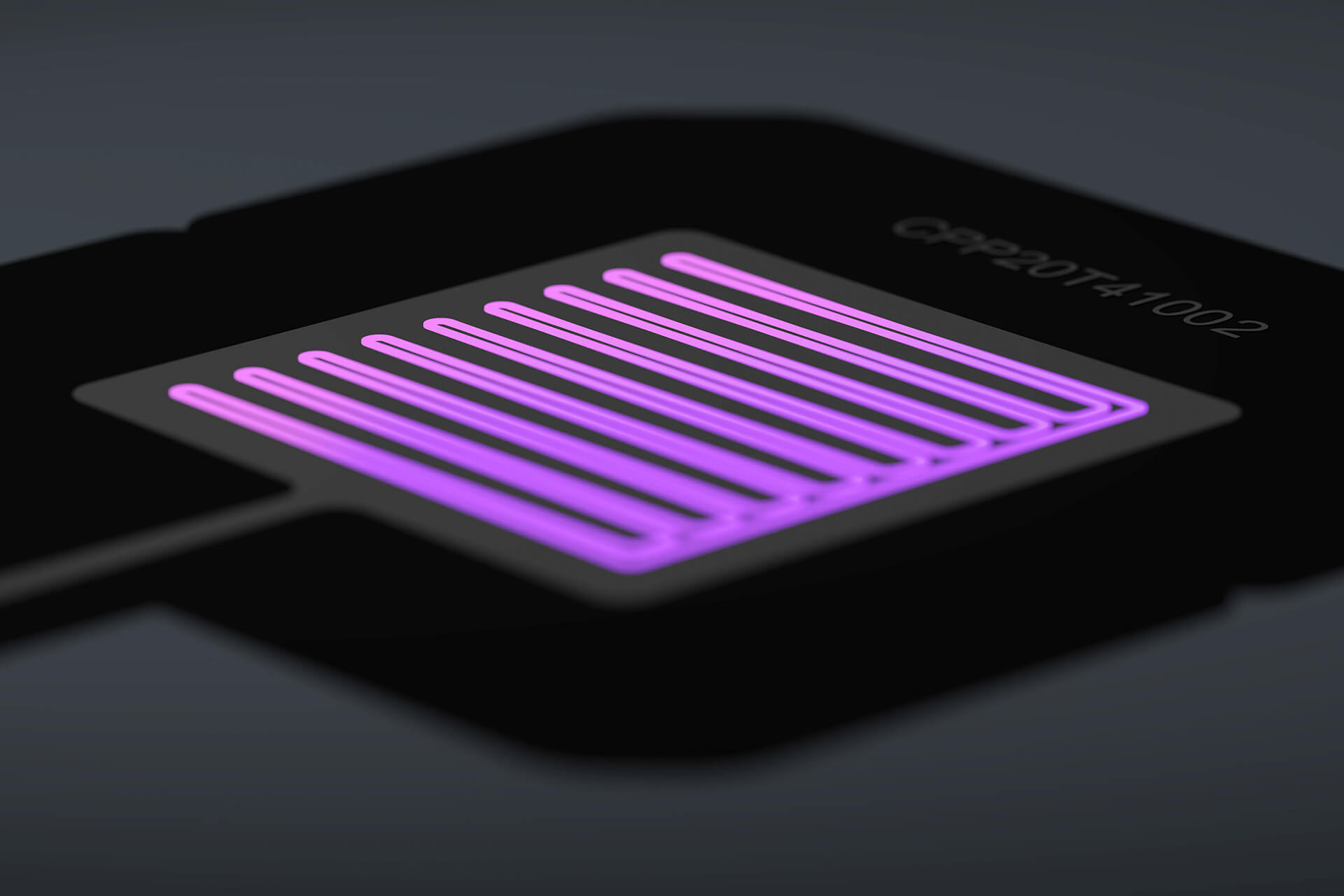

Coldplasmatech GmbH’s invention is a small white box, the “CPT®cube.” This device is cable-connected to the “CPT®patch” that is placed on top of the wound. It is a sterile, active wound dressing for single use. At the time Dr. Mahrenholz and his team were looking for a reliable development partner for the CPT®patch: from the initial idea to the mass-manufactured product. What they found was the tech-savvy experts at our Schreiner PrinTronics competence center who were thrilled to take on this challenge.

The requirements to be met by the high-tech wound dressing were and continue to be high, starting with the material selection that needs to be adjusted to and approved for the intended medical purpose. The printed conductor track structure must be very flexible while resisting several kilovolts—without causing an electric shock. Due to the extremely delicate structures, high printing and die cutting precision must be ensured. In addition, it was necessary to keep an eye on costs because the objective was to develop the product to industrial-scale manufacturing and launch on the mass market for healing chronic wounds. Ultimately, that needed to pan out not only in terms of technology but also in terms of price.

Despite being extremely thin and flexible: The CPT®patch consists of many different layers and is highly complex.

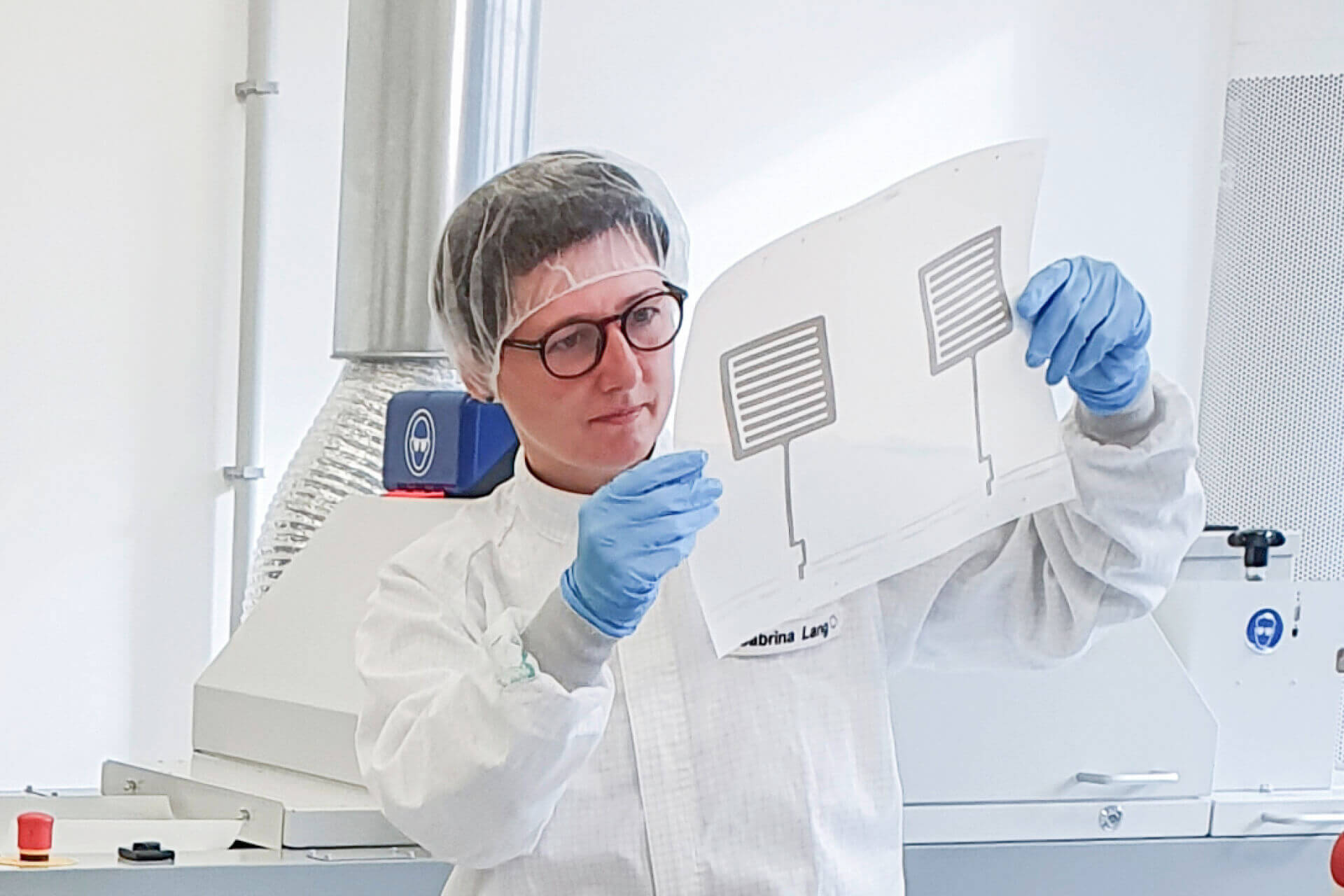

Juliane Tripathi, a team leader at the Schreiner PrinTronics competence center, describes the complexity of the technical challenges: “The composition of the CPT®patch is very complex. It consists of many layers—films, silver conductive pastes, protective varnish, and adhesives. At the same time, we were very limited in the selection of usable materials due to the biocompatibility requirements in a medical product.” Moreover, extremely strict requirements were imposed on technical cleanliness: “Even the smallest lint or other particles have a negative impact both within the process and in terms of the functionality of the finished product,” explains

expert Tripathi.

Her team had run initial trials in sheet-fed printing to provide Coldplasmatech GmbH with urgently needed prototypes for studies and approvals. “We selected various materials that were tested at the customer’s site. In several iterations, we managed to adjust the requirements to be met by the product and process to enable mass production. The key aspects were improved usability, cost efficiency, and manufacturing feasibility,” says Tripathi. The main challenges during the transition from mini-series to mass production are the automation processes, balancing of quality versus throughput, and process stability. “We’re very proud that the product is now fully produced in a roll-to-roll process and that we’ve even won such a distinguished award with it,” enthuses Juliane Tripathi.

What is cold plasma?

When additional energy is applied to a gas, the gas will transition into the “fourth” state of matter—the solid, liquid, and gaseous states are followed by plasma. The surface of the Sun, for instance, consists of this very hot matter. The technology for creating cold, gaseous, and skin-friendly plasma is new and a prerequisite for applying plasma to living cells.

Due to the plasma, the air between the CPT®patch and the surface of the wound transitions into an energetically active state, combined with the generation of alternating electric fields, light in the UV and infrared range, the formation of ions, and a slight temperature increase. The combination of these physical modes of action results in an antimicrobial effect of the physical plasma and promotion of wound healing.

Schreiner Group prints the silver electrodes onto a film with dielectric strength. This requires high-precision lamination and die cutting of the patch as well as extremely high fitting accuracy so that the plasma can ignite in the application.