Fascinating Research

SCHREINER GROUP

Fascinating Research

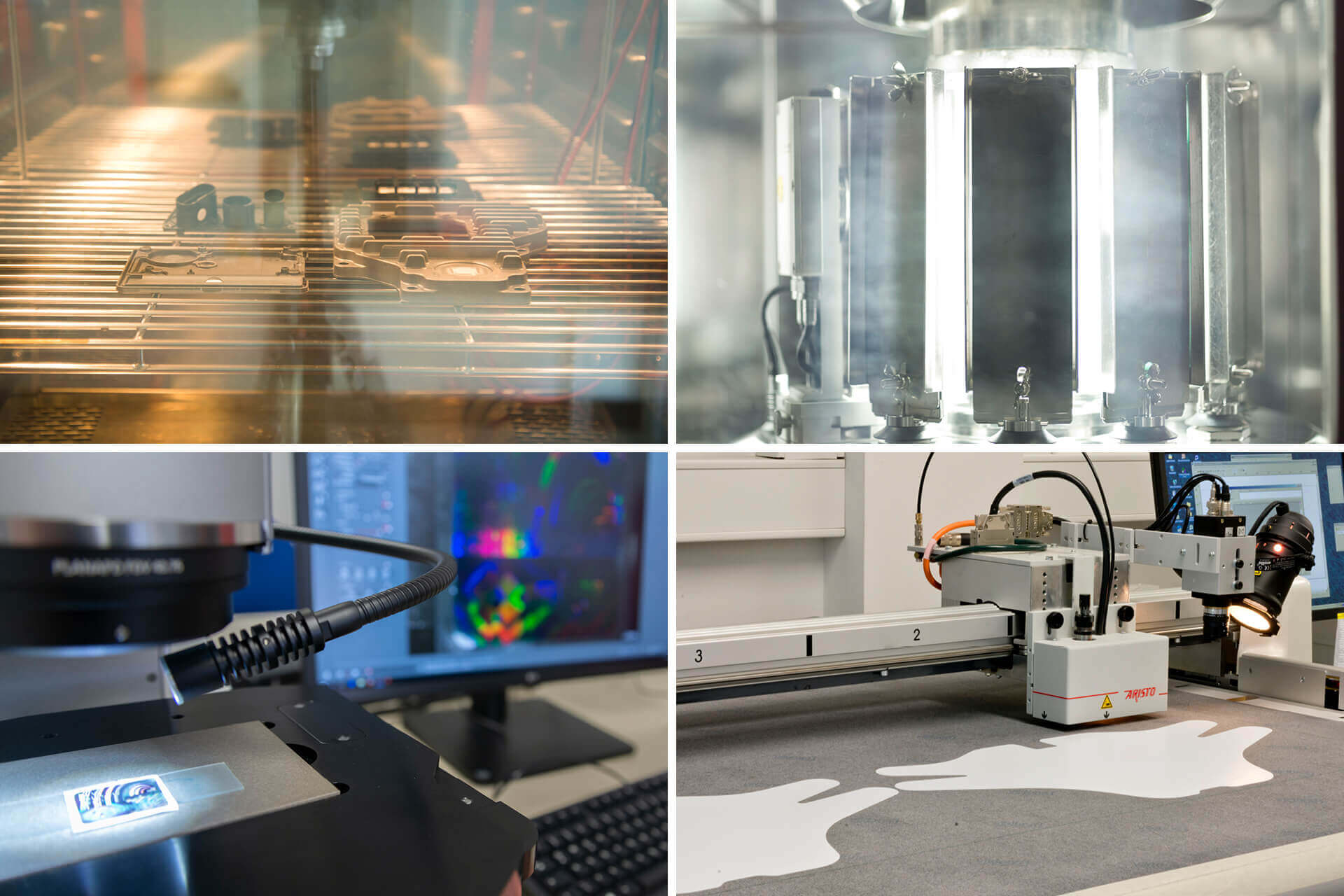

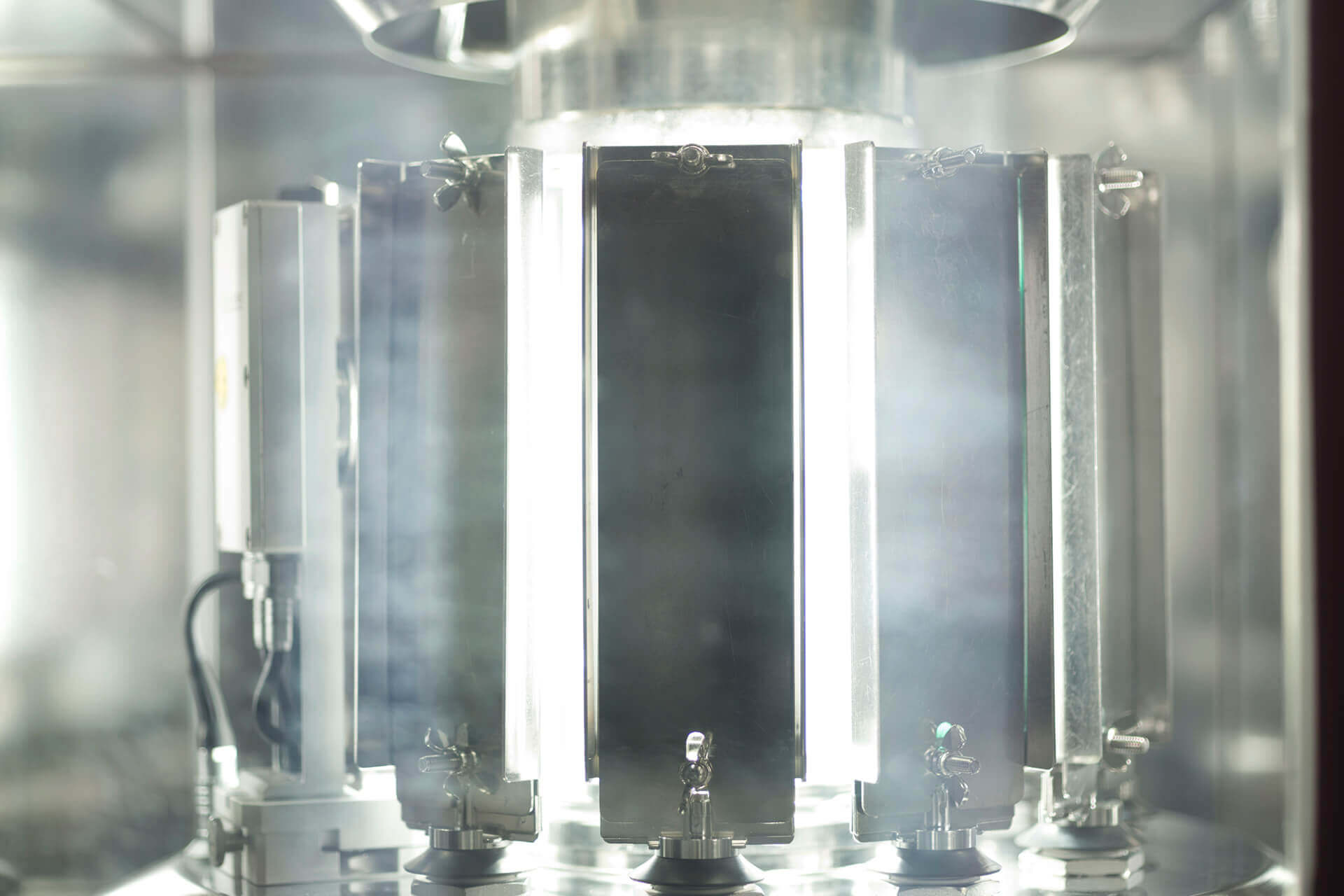

“We can use that to create UV weathering conditions. In other words, we investigate the impact of solar irradiation on a material within a short period of time,” says Dr. Jens Vor der Brüggen while pointing to a large simulator system. The PhD chemist leads the Research + Development (R&D) team at Schreiner Group consisting of more than 30 specialists. Brimming with excitement, Dr. Vor der Brüggen provides a guided tour of the laboratory that is packed with cabinets, ovens, microscopes, and other types of equipment. “Although we are in our own world here,” says the head of R&D with a laugh, “we work together very closely with all the other functions of the company.”

An average of seven per working day, totaling 1,800 for the whole year: That’s how many test requests the laboratory and prototyping department handled in 2021. The laboratories’ range of services extends from functional testing to analytics. Environmental simulations such as UV weathering and numerous other tests enable the simulation of long-term environmental effects, whereas tests of materials and products serve to investigate durability or mechanical properties such as adhesion or flammability. In addition, the functionality of products and materials can be tested in the laboratory.

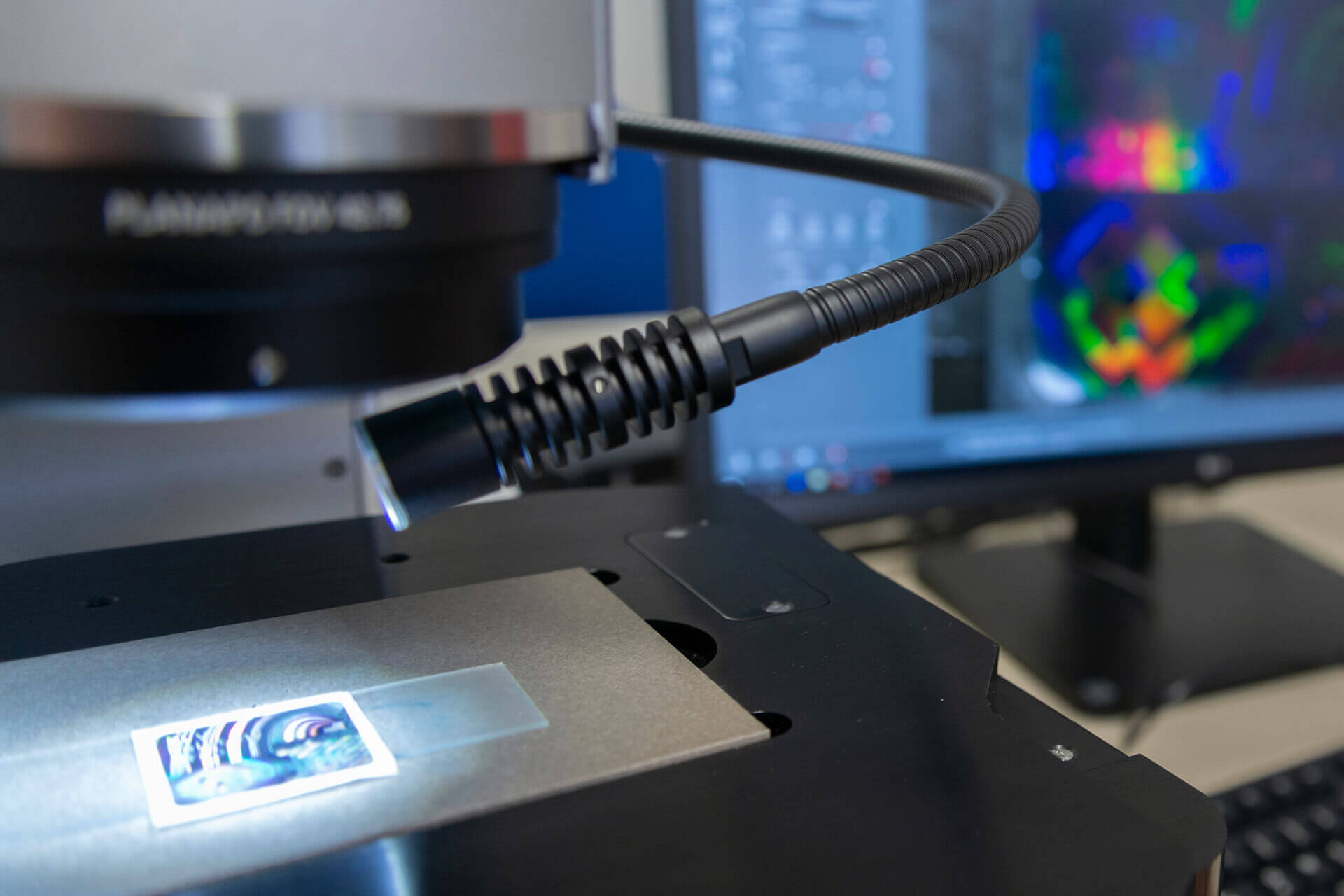

It is the extensive array of analytics equipment that makes Schreiner Group stand out. Medium-sized companies rarely have such opportunities in-house. “For us, reliable analytics is the basis for every product development,” explains the head of R&D. “We select the suitable equipment, methods, and technologies according to the questions that need to be answered.” Schreiner Group uses infrared and UV spectroscopy that serves to determine the molecular structure of materials for example, contact angle measurements for surface tension analysis, as well as microscopy and scanning electron microscopy for surface investigations in the nanometer range.

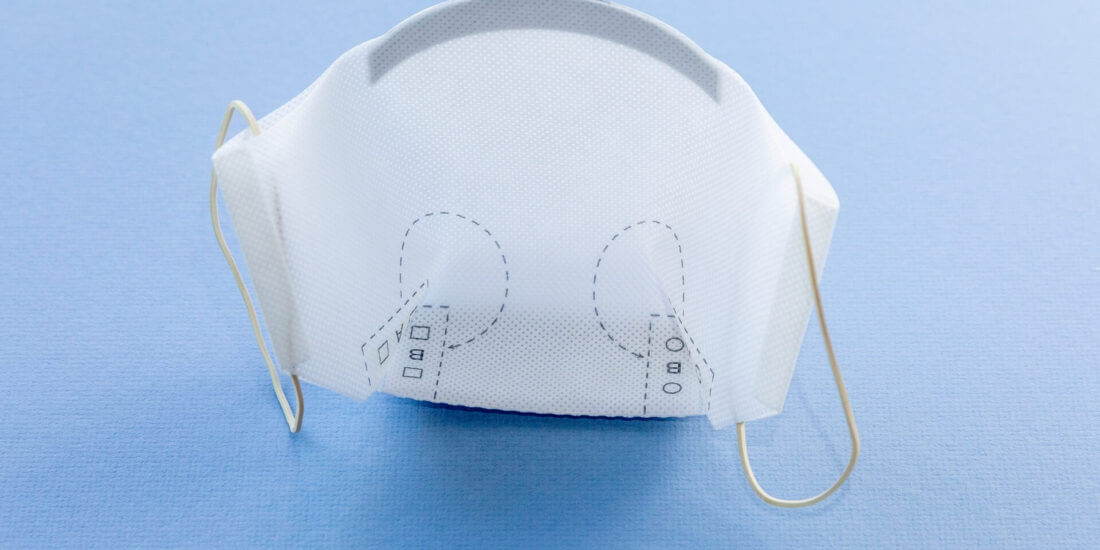

In addition, in-house prototyping enables the professional fabrication of individual items. These unique specimens not only serve as samples to be shown to customers and trade fair visitors but also as design and functional samples for product development.

“The countless combination options of individual tests are our great forte,” says Dr. Jens Vor der Brüggen. “We are happy that we can do everything in house because no external laboratory alone can cover such diversity.” That is indispensable for many product qualifications particularly in the pharmaceutical and automotive markets. That is why the wide range of R&D services is tailored to the product and technology portfolio of Schreiner Group and its business units.

How Pharma Labels Become Sustainable

The development of sustainable labels is a good example that provides specific insights into the work of the research and development team. “Our objective was to pre-qualify sustainable materials in response to a request by the Schreiner MediPharm business unit,” relates Dr. Vor der Brüggen. We started by selecting a range of sustainable film materials. Their properties were subsequently compared in various tests and simulations: How much elongation can the materials resist? How do they cope with specific temperatures? How good are ink adhesion and ink durability? All these questions were answered in a large number of tests. Nine materials were identified as suitable. “We took a selection of those materials to produce further samples for qualification and for display at a trade fair,” explains the head of R&D. “They met with very favorable customer response. Now we are working on additional material qualifications and on qualifications for use by Schreiner MediPharm customers.” Additional information about sustainable pharma labels can be found on pages 14 and 15.

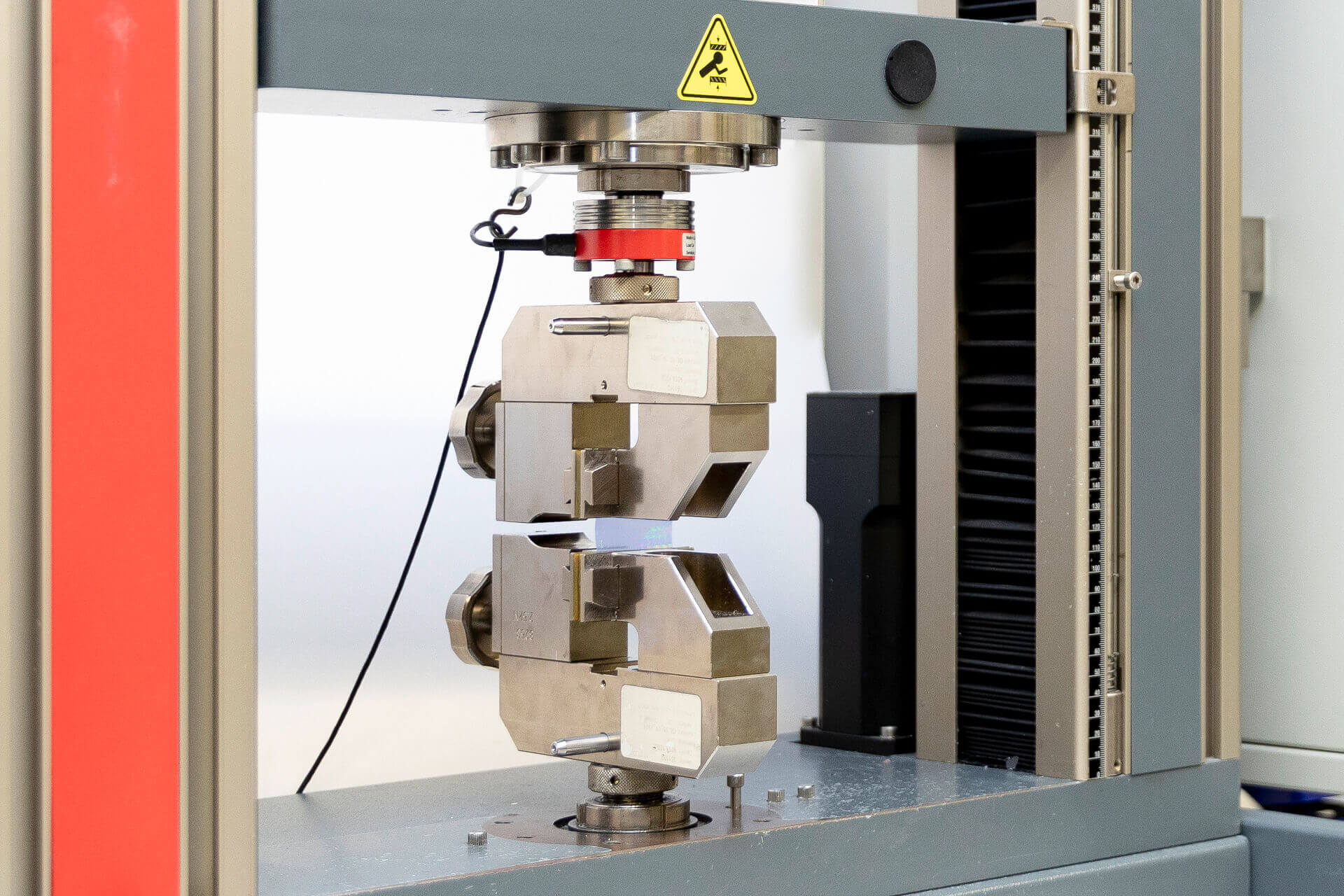

Next-Generation Pressure Compensation Seals

The research and development team also conducts extensive material and product tests for the Schreiner ProTech business unit. They include the qualification of new membrane materials for use in pressure compensation seals (PCS). A PCS consists of a watertight and dustproof yet air-permeable membrane, enabling air exchange in housings and protecting the electronics against liquid media and dirt. “For these uses, the materials must be tested for very specific properties. The qualification for new membrane materials involves an extensive product validation program including numerous laboratory tests,” says Dr. Vor der Brüggen, “including airflow and water ingress point combined with climatic storage as well as mechanical and chemical resistance tests. We continuously extend our product validation program and perform product requalification tests at regular intervals.