Etching, Cutting, Printing: An Overview of Antenna Production

SCHREINER LOGIDATA

Etching, Cutting, Printing: An Overview of Antenna Production

For more than 20 years, Schreiner Group has been offering its customers a wide variety of customized RFID solutions. Obviously, our experts from Schreiner LogiData are focused on the various antenna production technologies as well. Their knowledge of the variety of methods enables the development of tailored solutions for the customers’ specific requirements.

A brief overview:

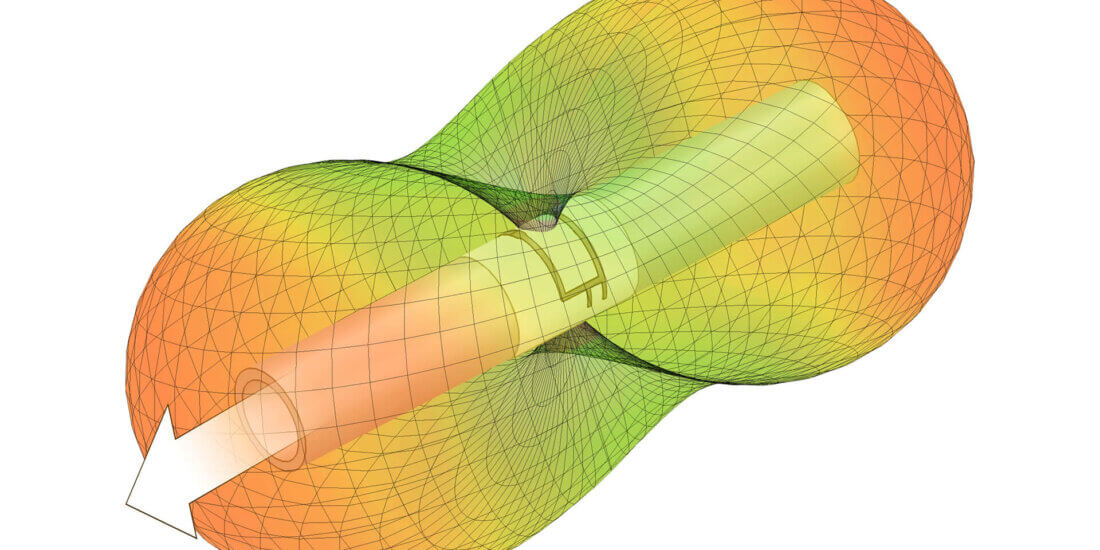

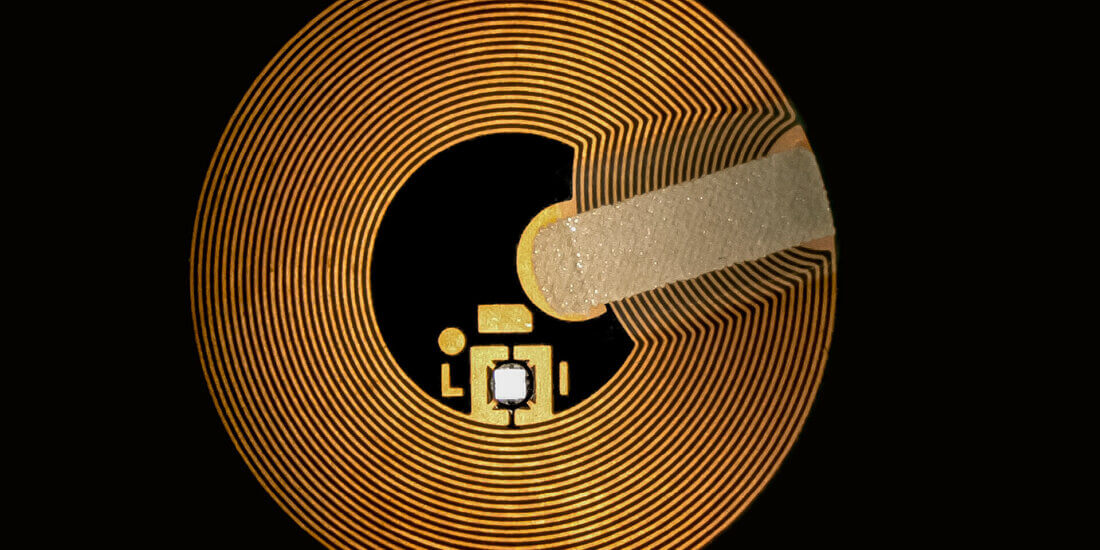

Etching remains the dominant technology for mass production of RFID antennas. It is used for aluminum and copper antennas and offers high resolution at comparatively low costs. Another commonly used method is cutting—both mechanically and by means of lasers. It is particularly wellsuited for specialty applications in the UHF range and laser cutting enables rapid implementation of design modifications. Printing of RFID antennas enables the utilization of different carrier materials and is particularly well-suited for specialized applications such as stretchable substrates, on paper, or void structures. For smaller volumes and quick design changes, this method is ideal despite slightly higher costs and disadvantages in terms of conductivity.

But innovative and more eco-friendly alternatives to conventional antenna production exist as well:

One option, for instance, is to press metal-coated films onto a 3D printing plate and to remove raised surfaces by means of abrasion, which requires less chemicals and enables quick design changes. Another variant of antenna production uses a design that is sprinkled with metal powder, sintered, and compacted, because of which it can be used on paper and hence is free of plastics. Another existing plastics-free, digital technology uses a laser to write on a metal foil which is subsequently ablated. However, there is currently a downside to all those alternatives: they are costly and the number of available suppliers is still very small at the moment.

Schreiner Group’s customers are provided with precisely the label solution that’s the right fit for them.

A comparison shows that each manufacturing technology has its own cost structure and not every technology is suitable for all materials. Some offer flexibility in design while others reduce the environmental footprint. By the same token, the choice of the suitable technology also depends on the specific requirements of the application and the production volume. Our experts include all that, paired with solid industry knowledge, in their planning process of developing new RFID applications.