Effective Closure: Film-Based Covers Protect Housings

SCHREINER PROTECH

Effective Closure:

Film-Based Covers Protect Housings

Smaller, lighter, and simpler: That’s what components should be—not only in the automotive industry. There’s an obvious trend to “keep it simple” while the exacting demands to be met by the components continue to exist. In the form of the Film-Based Cover (FBC), Schreiner ProTech offers its customers an optimal solution.

Currently, plastic component housings are typically closed using injection-molded covers. However, those covers entail high tooling costs and require a certain amount of space during shipping as well in relation to installation.

A film-based cover as a housing closure provides a simpler solution reducing handling complexity. It features a strong polyester film that is cut to size and delivered on rolls. Its benefits are obvious: The film considerably helps save weight of the entire component—up to 85 % weight savings are possible! Lightweight and flat, the film-based solution provides a watertight and dustproof closure and withstands chemical, mechanical, and thermal stress. Consequently, a wide variety of challenging automotive applications can be implemented with it. Schreiner ProTech’s applicator system enables precision application of this substitute for injection-molded covers. Laser welding creates a permanent and reliable bond between the film and the housing.

The possible integration of pressure compensation seals is another advantage of the film-based solution. Schreiner ProTech’s total solution is rounded out by the significant cost benefits of the Film-Based Cover for customers.

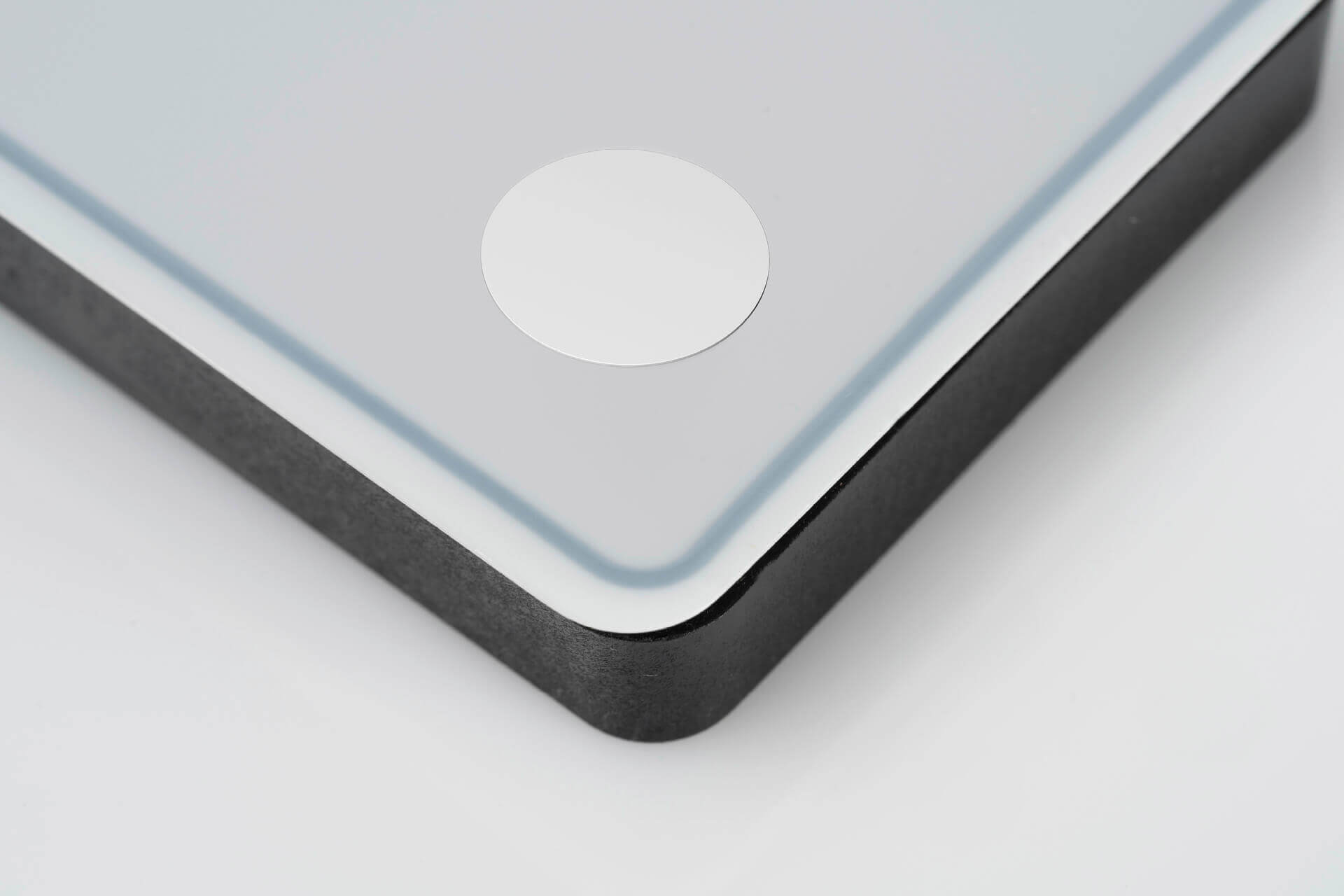

Attractive alternative: Film-Based Covers are clearly lighter and flatter than injection-molded housings. In addition, they can be provided with (left) and without (right) pressure compensation seals.

Weight savings of up to 85% are possible.

Film-Based Covers can be used in various vehicle applications. Whether in electronic control units or sensor housings, the film-based components are advantageous wherever weight savings and minimal space requirements are crucial.