E-Mobility: Pressure Compensation While Charging

SCHREINER GROUP

E-Mobility: Pressure Compensation While Charging

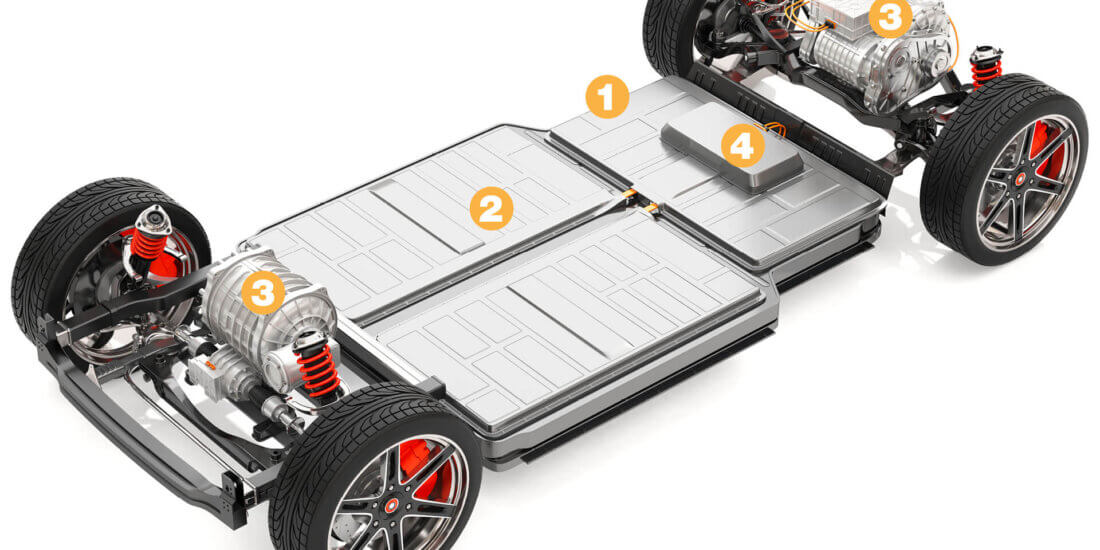

Electric vehicles are an important element in mobility of the future and many of them can already be found in garages today. Charging them requires an infrastructure of charging stations for which Schreiner ProTech is now providing pressure compensation seals and protection films.

During the charging process of an electric car high levels of current are generated that in turn cause high temperatures in the areas of the charging socket and charging plug. These temperature fluctuations result in pressure differences in the electronic housing. Schreiner ProTech has developed a membrane for the pressure compensation that is necessary to protect electronic housings against damage. Moreover, in specific installation scenarios, a protection film can dampen the noise that occurs when the cover contacts a rear panel.

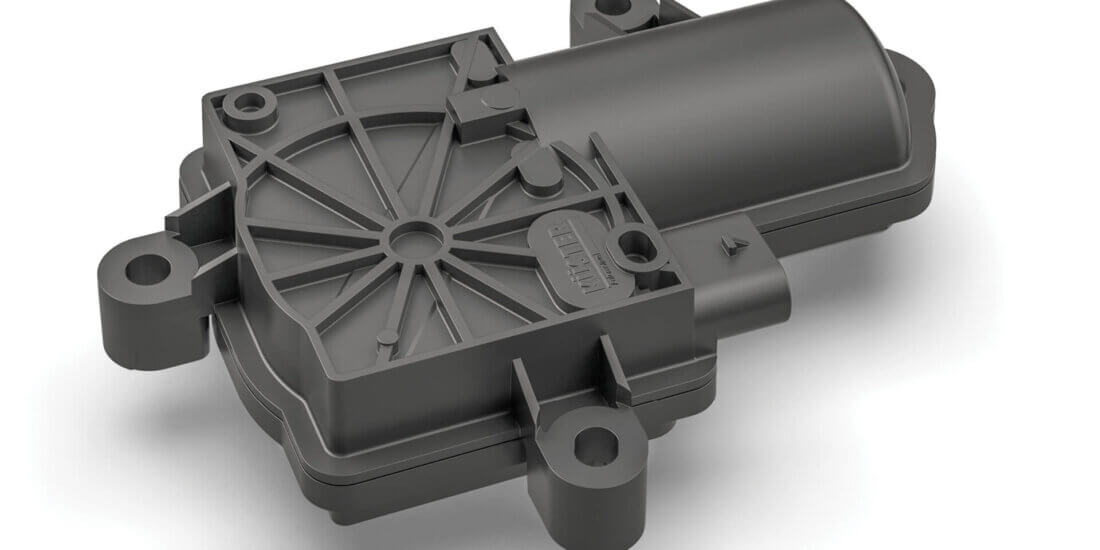

Automotive manufacturers require high steam jet resistance in the area of the charging sockets. The flat design of the highly resistant pressure compensation seal (PCS HighProtect) withstands these requirements while providing engineers with ample freedom of design. Up to now, snap-fit versions leaving minimal scope for design have frequently been used for pressure compensation. Additional benefits of Schreiner ProTech’s pressure compensation seals are lighter weight and higher processing cost efficiencies than the previously used snap-fit versions supplied as bulk material.

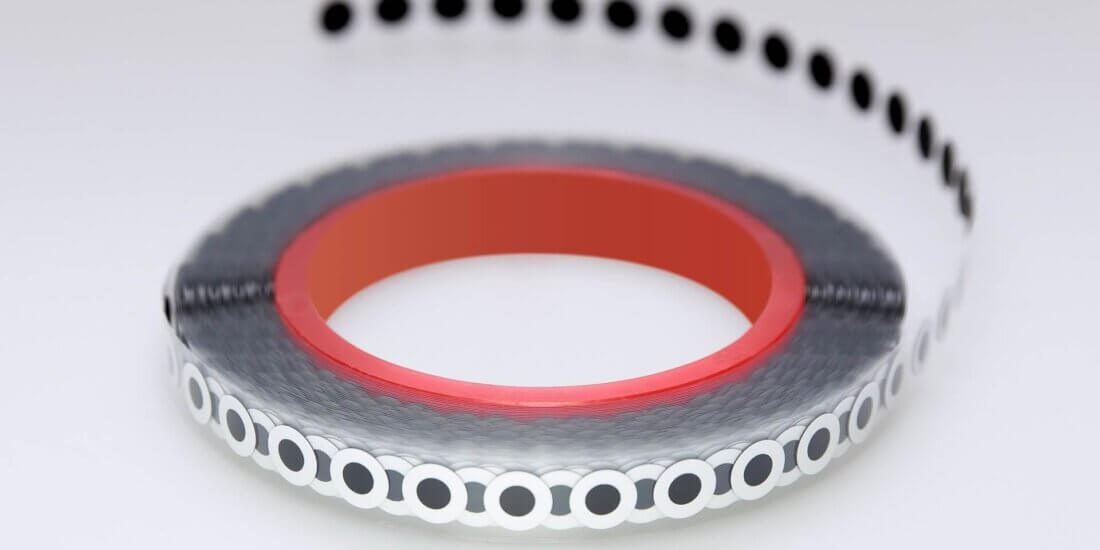

Because the e-mobility sector frequently entails the production of very small volumes the flexibility of being able to manufacture several types of charging sockets on one line is important. Schreiner ProTech offers customized specialty solutions for the manufacturing cell enabling several versions to be processed. The business unit’s experts provide advice on the correct position and installation circumstances such as the design of the protective edge around the pressure compensation seal and the cavity in which it sits. In addition, Schreiner ProTech offers support in the area of testing, for which a dedicated research and development department is available.

For the pressure compensation membrane’s processing cell, Schreiner ProTech offers customized specialty solutions.

Pressure compensation seals for e-mobility frequently have to be produced and processed in small volumes.

The pressure compensation seals for charging sockets exhibit particularly high steam jet resistance.