Durable Parts Marking in Harsh Settings

SCHREINER PROTECH

Durable Parts Marking

in Harsh Settings

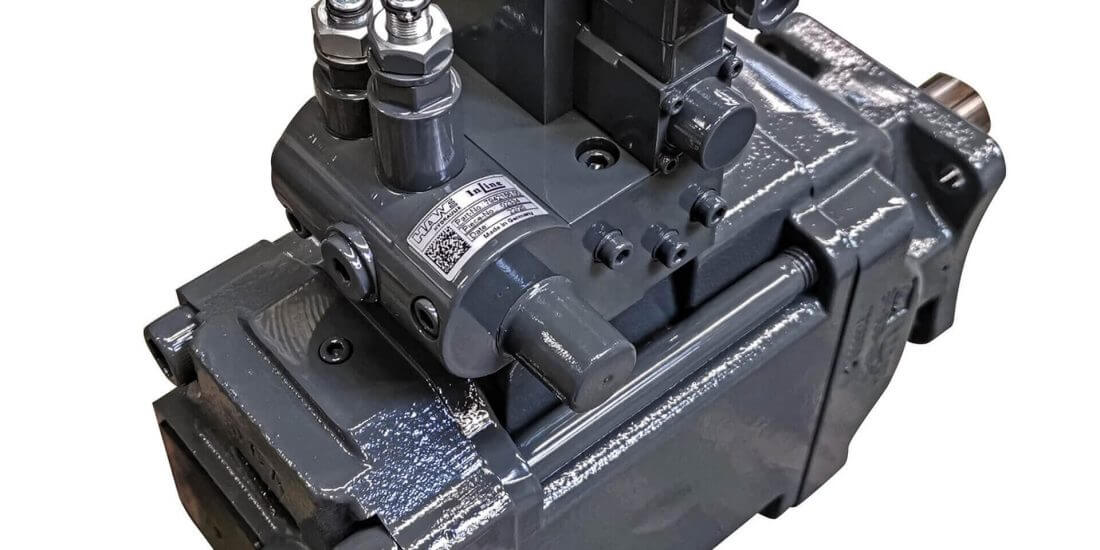

In mechanical engineering, many permanently marked components have to be provided with a protective coating—not just in production but also later following a repair. In both cases, it is important to mark the product across the entire process. In addition, the label has to resist adverse ambient conditions in all phases of the product’s lifecycle so that product identification by means of the label is ensured at all times. For these purposes, Schreiner ProTech has developed a paint-mask label and the corresponding dispensing system.

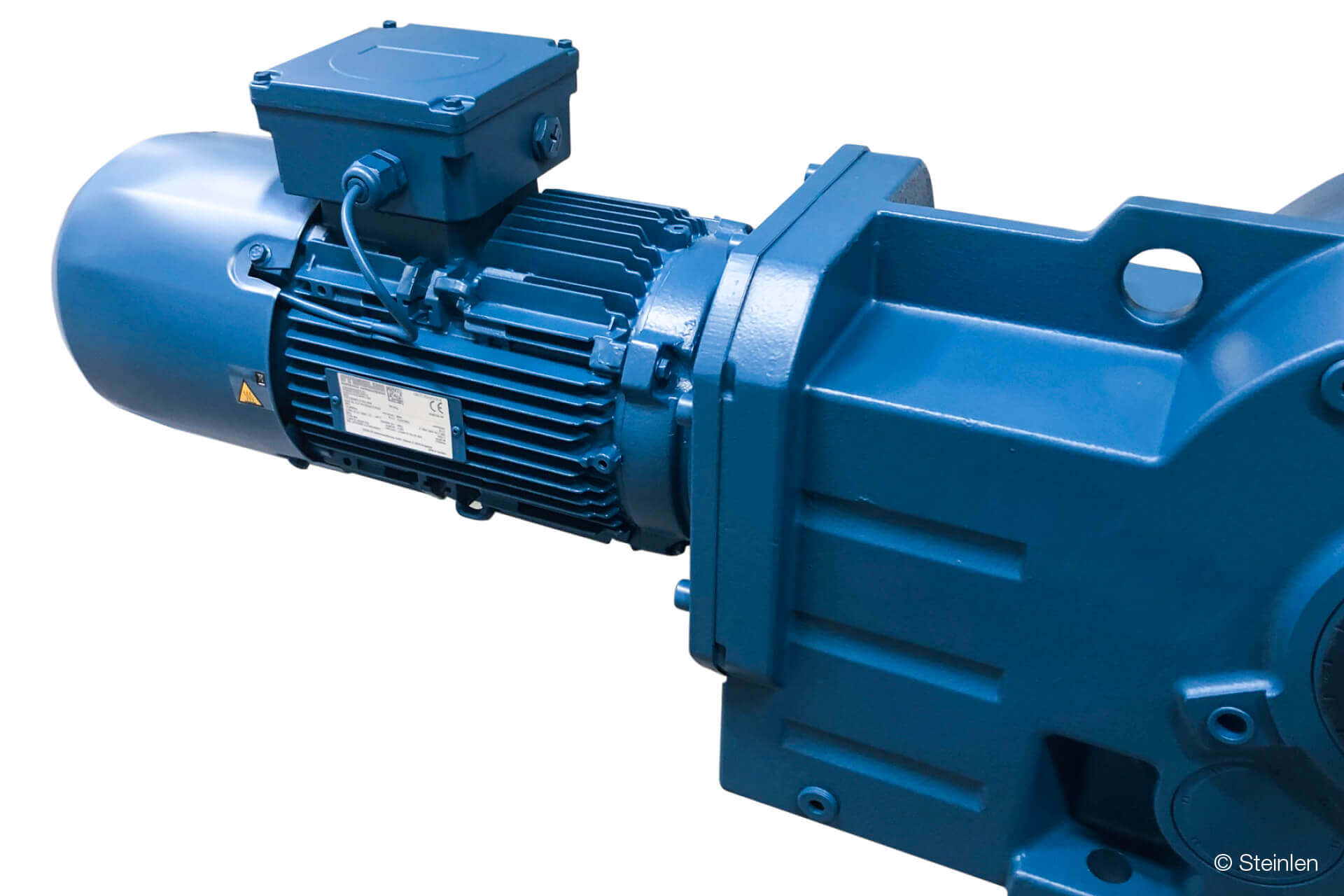

Steinlen Elektromaschinenbau GmbH in Hanover is specialized in the repair, maintenance, and manufacturing of drive-technology components, especially gear motors that are provided with their protective coating in a modern painting center. Previously, the nameplate for marking the product could be applied only after the painting process so that the product was not clearly identifiable and trackable until it had left the paint shop.

Together with Schreiner ProTech, Steinlen has now managed to optimize an important part of the production process. The objective was to apply the nameplate before the painting process, which posed a challenge because the plate required suitable protection during painting. In addition, the adhesive of the label had to stick to a cast component with a rough surface. Plus, since a large product volume entails a large number of variants involving many different label sizes, each label is one of a kind.

With the Color Laser Film including a paint mask and the corresponding laser marking system from Schreiner ProTech, all requirements were satisfactorily met in an automated process. As a result, Steinlen can now cut and inscribe nameplates specifically for any customer order.

Laser-markable labels with integrated paint masks enable permanent marking of components, ensuring their reliable identification even on rough substrates and after the painting process. Due to the specific product features of Color Laser Film, the inscription can be performed through the paint mask, which eliminates the usual need for subsequent application of the paint mask. The paint mask including the paint is peeled off by means of a starter tab, which makes the nameplate legible again.