Customized Services: Agile and Efficient Supply Chain

SCHREINER MEDIPHARM

Customized Services:

Agile and Efficient Supply Chain

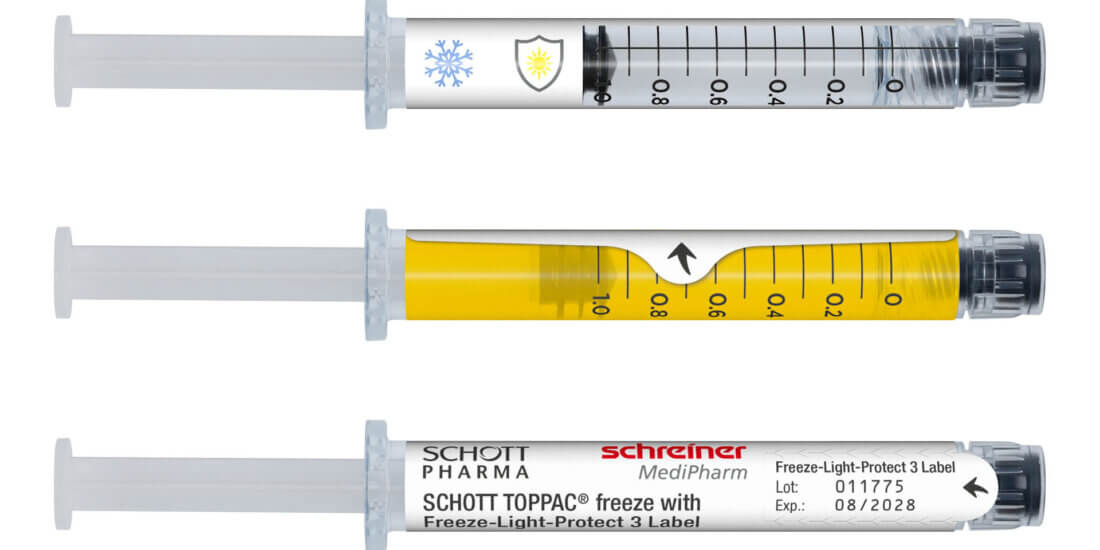

Country-specific regulations, various languages, and special packaging formats—a reliable and efficient supply chain poses special challenges to pharmaceutical manufacturers and their suppliers. In addition, increasing specialization of drugs—for instance in the area of personalized medicine—as well as the demand for small batch sizes, many varieties, and short lead times call for reliable and flexible processes to ensure security of supply. Therefore, Schreiner MediPharm supports its customers in continuously improving their supply chain processes and offers special services to optimize them.

All producers of pharmaceuticals face specific challenges in their supply chains calling for customized solutions to enhance supply chain agility and efficiency: Schreiner MediPharm offers its customers a wide variety of services tailored to their respective needs and particular requirements. Close collaboration and integration with the customer including all stakeholders involved is important in this regard. Examples of solutions for an optimized supply chain are Late Stage Customization, Make-to-Stock, and Vendor Managed Inventory.

Late Stage Customization

Customer-specific labels including all functional features are pre-produced in large quantities and placed into intermediate storage as semi-finished goods. As soon as the customer requires them, the pre-printed labels are customized using digital printing. For instance, country-specific text, drug strength, and color codes, or variable data can be inserted. Subsequently, the finished functional labels are shipped on short notice. As a result, Schreiner MediPharm can respond quickly and flexibly to customer wishes.

MTS (Make-to-Stock)

Make-to-Stock refers to pre-manufacturing larger volumes of a label as a finished product based on aggregated planning. However, the customer does not call off the entire production volume but only the respective demand for individual shipment. The remaining quantity is stored at Schreiner MediPharm until the customer requires it. This enables clearly shorter lead times and short-term adjustments of demand.

VMI (Vendor Managed Inventory)

In this case, the customer outsources the entire planning and scheduling process. Consequently, under a VMI arrangement, Schreiner MediPharm not only plans the production of labels per se but also their required quantities. These plans are based on the inventory and forecast data the customer transmits on a regular basis, i.e. the demand on article level. Close exchange and automated processes ensure reliable delivery performance and enable flexible response to fluctuating demand. At the same time, efficiency and transparency are significantly increased.