Container Management with RFID: Marking with Added Value

SCHREINER PROTECH

Container Management with RFID:

Marking with Added Value

As one of the world’s leading manufacturers of injection molding machines for plastics processing, manufacturing efficiency plays a major role for the family-owned company ARBURG based in the Black Forest. For further optimization and fitness for digitalization, the mechanical engineering business rolled out a smart container management system for internal transportation. The project was developed and implemented with Schreiner ProTech’s know-how and extensive RFID expertise.

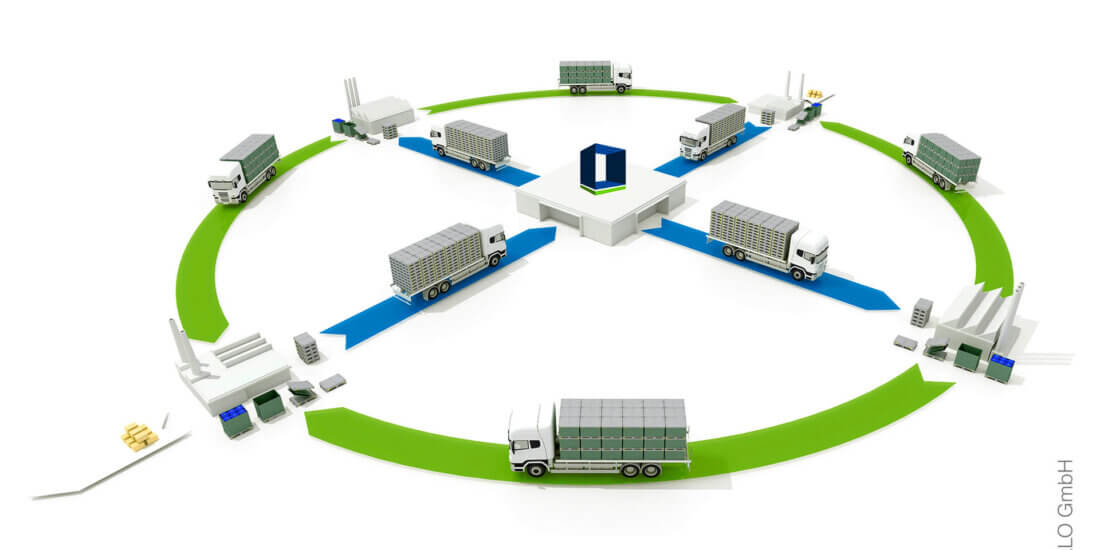

The containers in ARBURG’s factory halls travel several kilometers on average per week. The project was focused on getting a more detailed picture of the routes between the receiving department, the factory floor, and the shipping department and to increase the efficiency of the container circulation process: 100,000 containers in total were provided with both Datamatrix codes and RFID labels.

The demands made on the labels were high: Due to the washing processes, the markings not only had to be acid- and alkali-resistant but also perfectly harmonize with challenging container materials because ARBURG is currently using plastic, ESD-plastic, and metal containers.

“For us, it was important to work with an experienced partner in installing a system that lays the foundation for an RFID-based system while ensuring our VDA compliance every step of the way,” said Sarah Zinser, Team Leader, Logistics Planning at ARBURG.

The forward-thinking RFID solution enables full bulk reading, end-to-end batch tracing, and optimized empties management in real time. All labels have a read range of approximately 7 meters.

Smart container management with RFID: that’s not only a way to optimize processes and cut costs but an essential element on the road toward digitalization.