Clever Connection: Folding and Gluing

SCHREINER SERVICES

Clever Connection:

Folding and Gluing

In many places where different industrial parts or components must be joined together by means of a circumferential frame, maximum precision and tightness against external influences are required. However, conventional joining methods such as liquid gluing often lack precision and take a lot of time. Schreiner ProTech together with the experts from the Schreiner Services competence center has developed a solution that eliminates the disadvantages of classic joining systems.

Schreiner’s solution is based on two components: the so-called Folding Frame and the Folding Frame Processing System. What makes this solution so special?

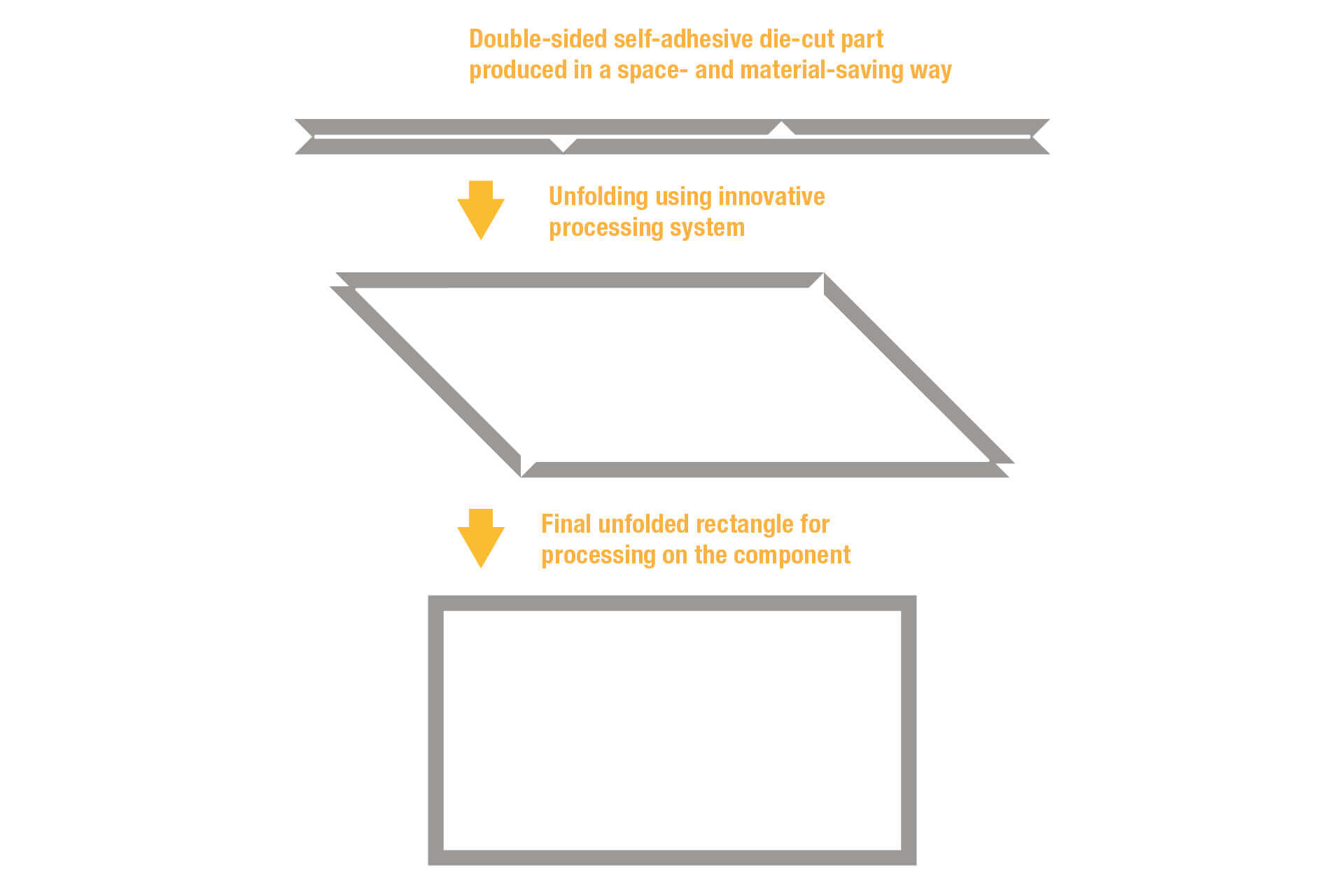

The Folding Frame features spacesaving, side-by-side production of the adhesive material.

Folding Frame

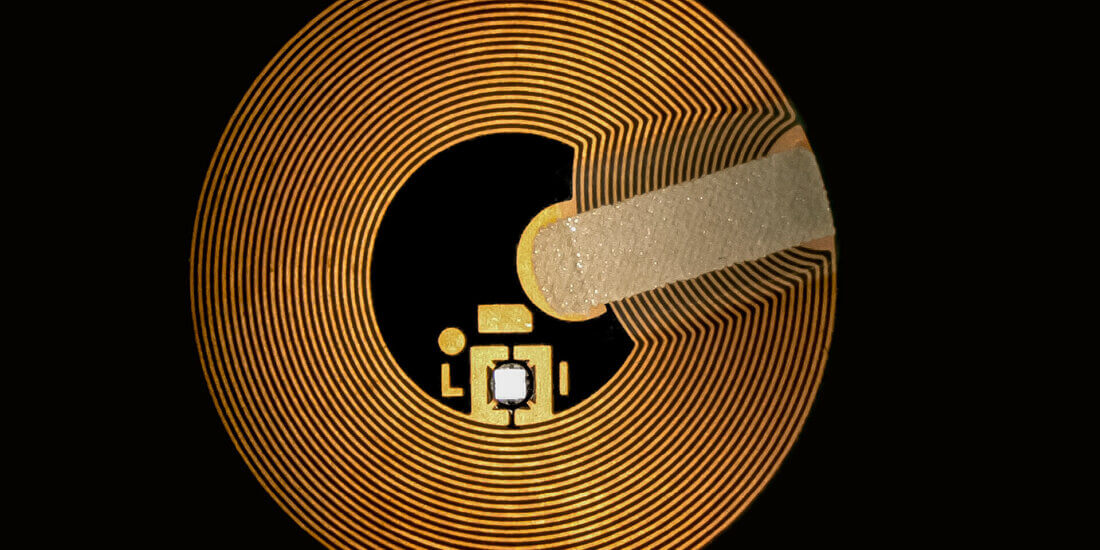

Unlike variants using liquid adhesive, where long curing times often slow down the manufacturing process and the flow characteristics of the glue usually prevent one-hundred-percent precision and cleanliness of creating the adhesive bond, this variant using foam-based adhesive tapes is fast, easy, and eco-friendly. Due to the creation of a small, foldable frame version, a full-surface outer frame can be avoided, and in-process material consumption can be significantly reduced. In the case of the Folding Frame, the adhesive material is produced side-by-side in a space-saving way. The adhesive tapes remain connected at the ends to subsequently ensure tightness—a major advantage compared to conventional adhesive tape solutions.

Folding Frame Processing System

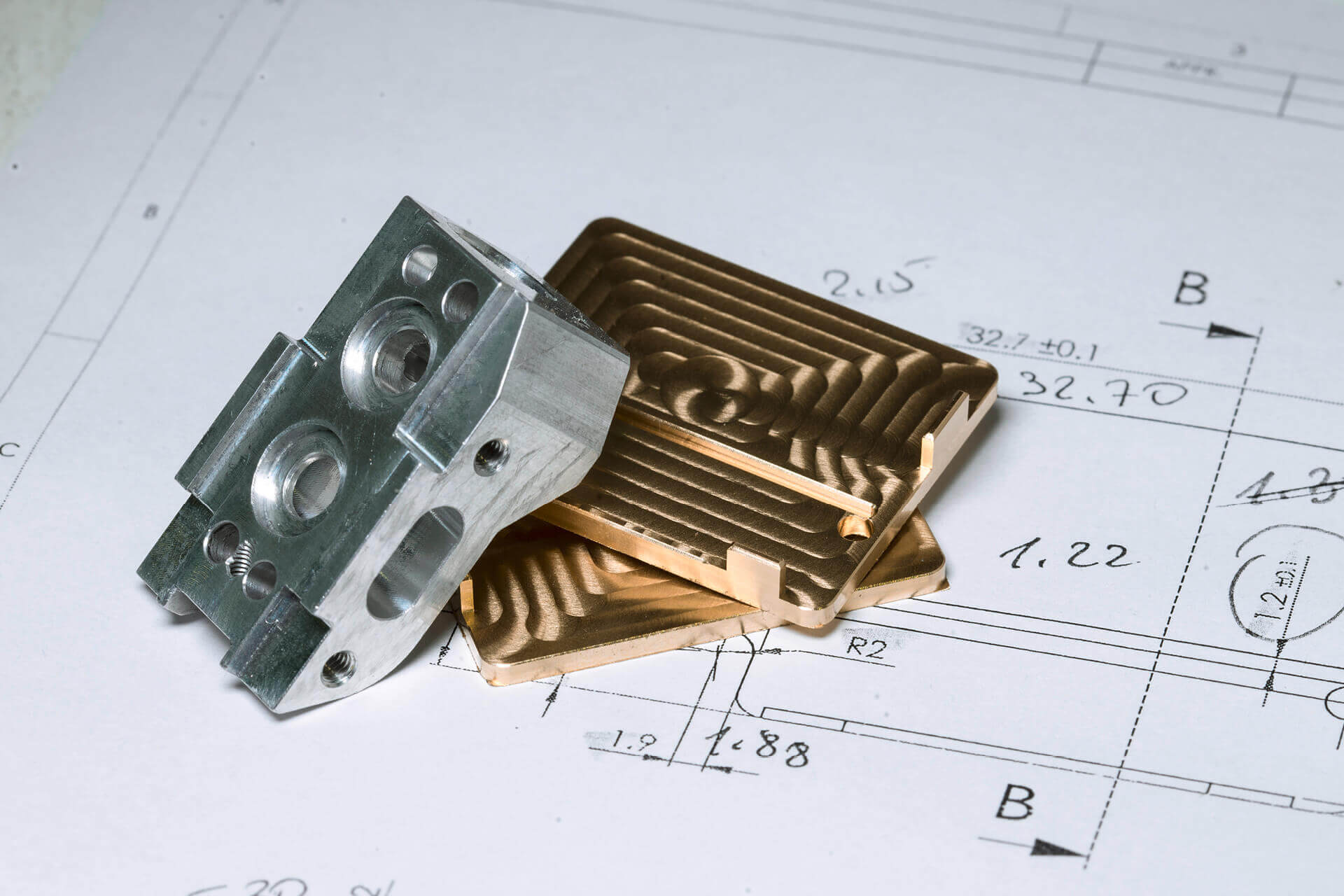

The Folding Frame Processing System is like the icing on the cake and makes this angular adhesive bonding solution truly unique: it enables absolutely precise positioning of the adhesive tapes. “At the competence center, we thought about how we could simplify the application of the tapes while ensuring high levels of precision,” says Michael Reineke from the Schreiner Services competence center, summarizing the situation. The result is a semi-automatic application system that picks up the adhesive tapes, unfolds them to create a frame, and joins the components together. That ensures high application accuracy and reproducibility. For the customer, it translates into significant time and cost savings and a reduction of potential mistakes in manual processes.

The processing system can be used whenever shapes with at least four corners exist. The Folding Frame Solution, for which a patent application has been filed, is equally efficient and versatile: “Whether it comes to precise fastening of displays,” explains Product Manager Markus Loris from Schreiner ProTech, “the equalization of irregularities or height differences, damping of vibrations, or sealing to keep out dust and splash water, thanks to its versatility and strength, the Folding Frame Solution can be used in a wide variety of markets and is absolutely in line with industry’s lightweight design trend.”

The splash water- and temperature-resistant Folding Frame Solution is not only a true alternative in the marketplace but also a good example of how Schreiner Group can deliver a product and matching processing system from a one-stop shop thanks to a well-gelled team.