Clearly Separated, Precisely Combined

SCHREINER SERVICES

Clearly Separated,

Precisely Combined

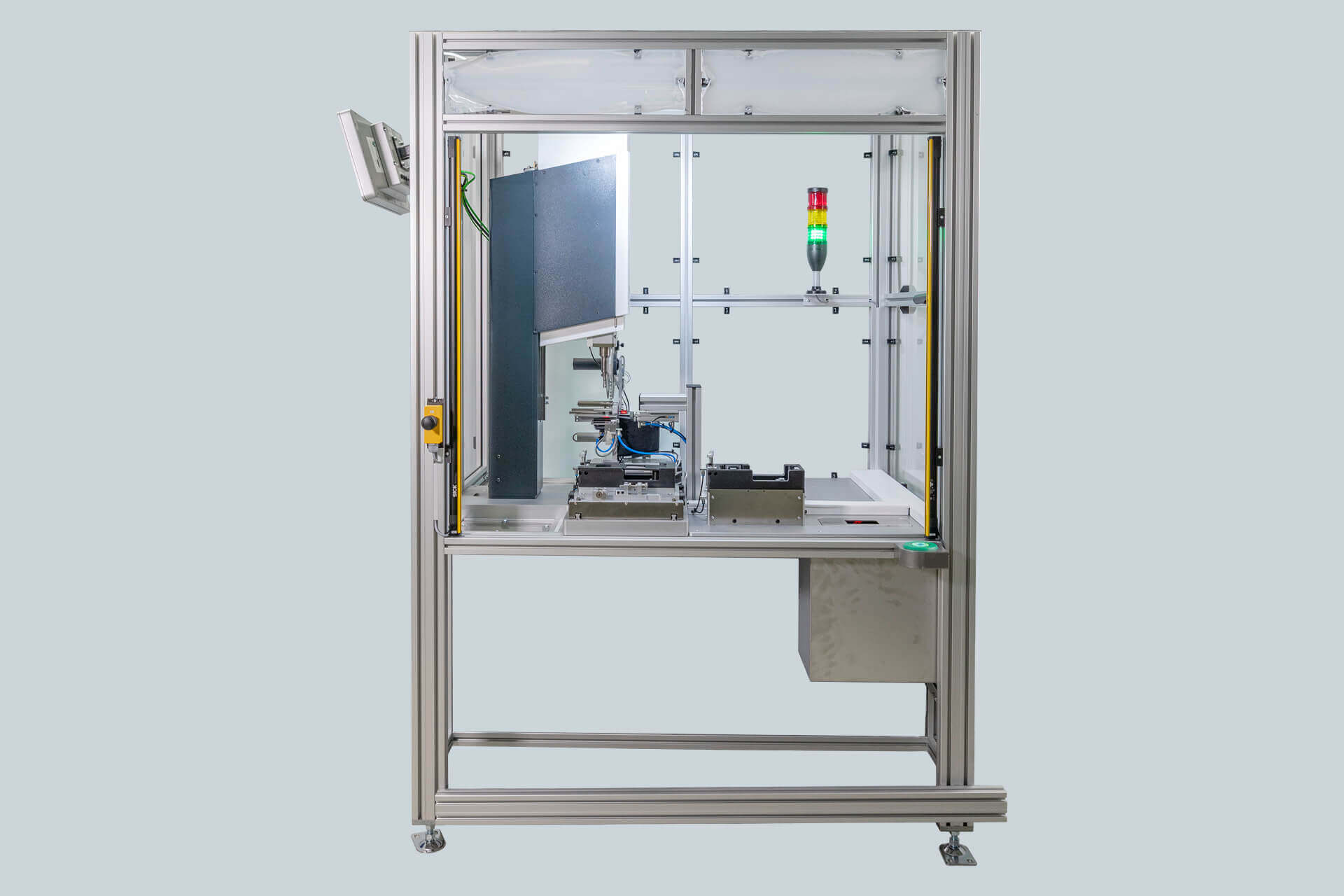

All-in-one often sounds enticing: fewer steps, less effort. Yet sometimes it pays to deliberately split processes. That’s exactly what the team of the Schreiner Services competence center did in the case of an ultrasonic welding unit for Pressure Compensation Seals (PCS). An approach that noticeably enhances stability and process reliability.

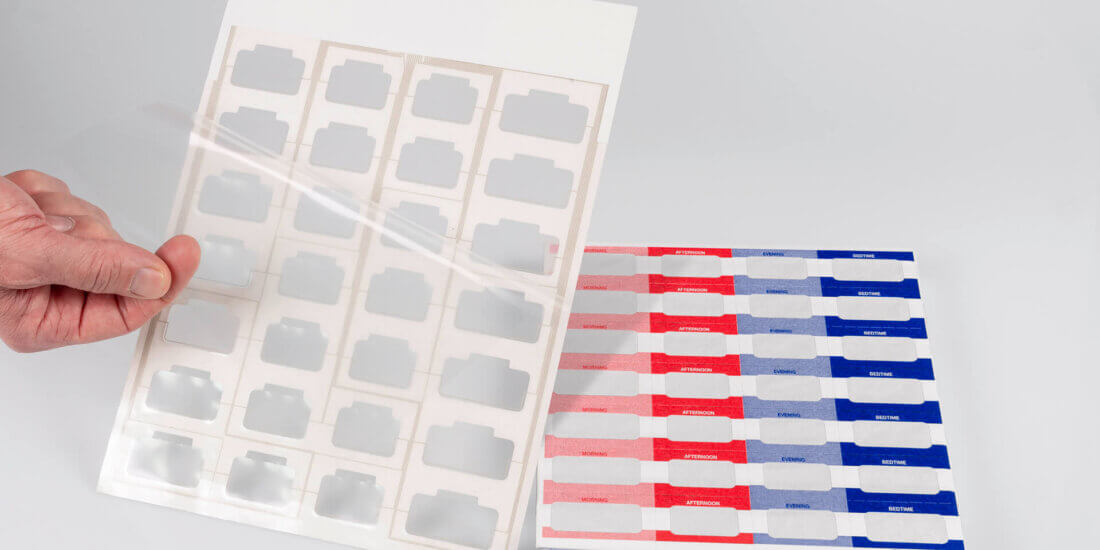

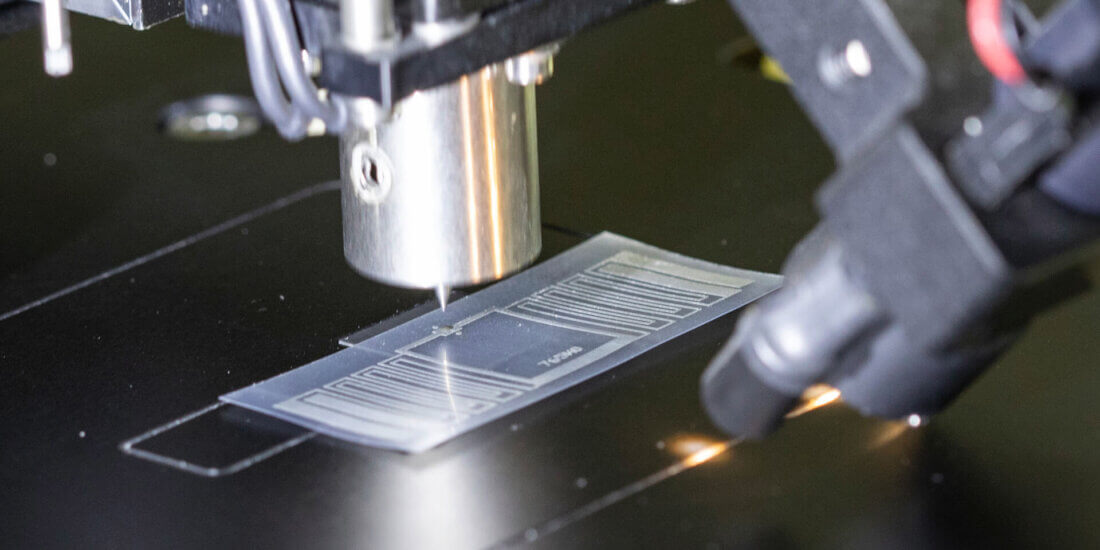

In the case of many applications, the sonotrode must do not just one but two jobs in terms of ultrasonic welding of membranes: It first cuts out the membrane and then welds it onto the component. That means it must have sharp edges, which makes it prone to wear. This results in several potential sources of defects, which poses a risk especially in the case of large volumes.

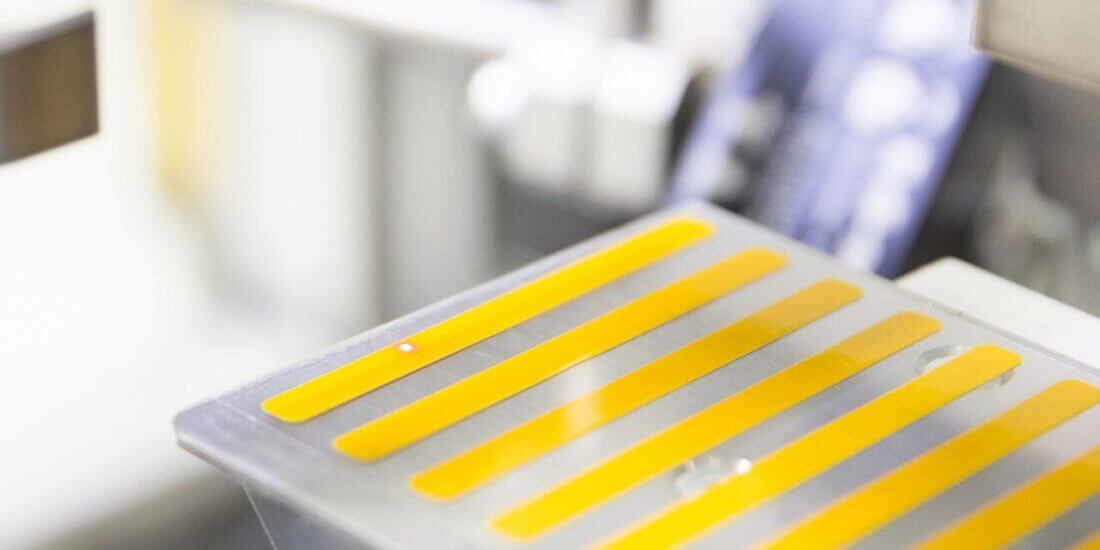

That’s exactly where the new solution comes into play: It deliberately splits the previous process into two steps by using pre-cut membranes. At Schreiner Group, that step is performed on high-performance cutting machines in regular production. “In that case, the sonotrode can focus on its primary task: precise welding in a reliable process. Without the additional cutting function, its geometry remains stable and its service life clearly longer. The result is a robust, durable process with far less failure potential,” explained Michael Reineke, Head of the Services competence center.

Automatic Precision Dispensing

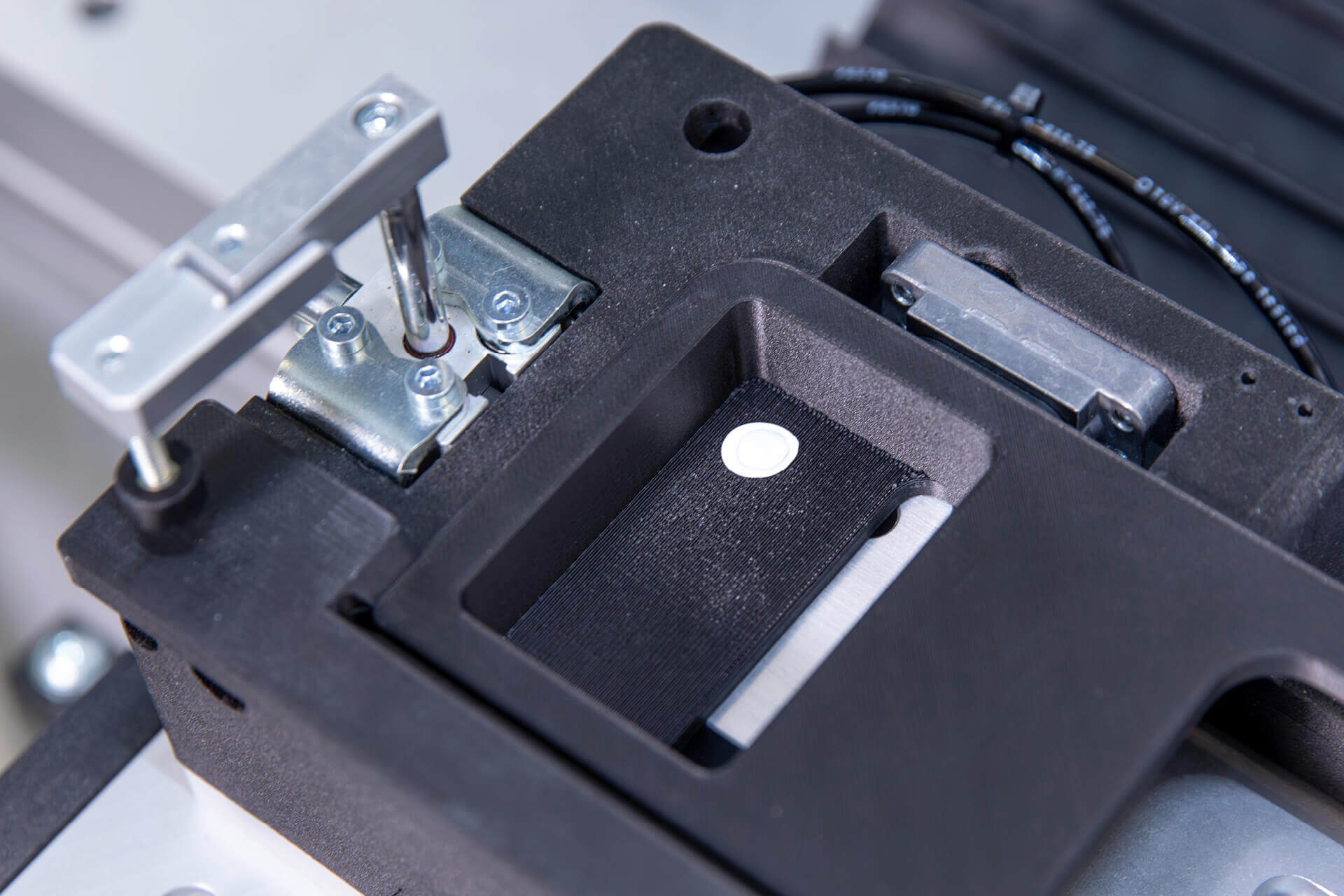

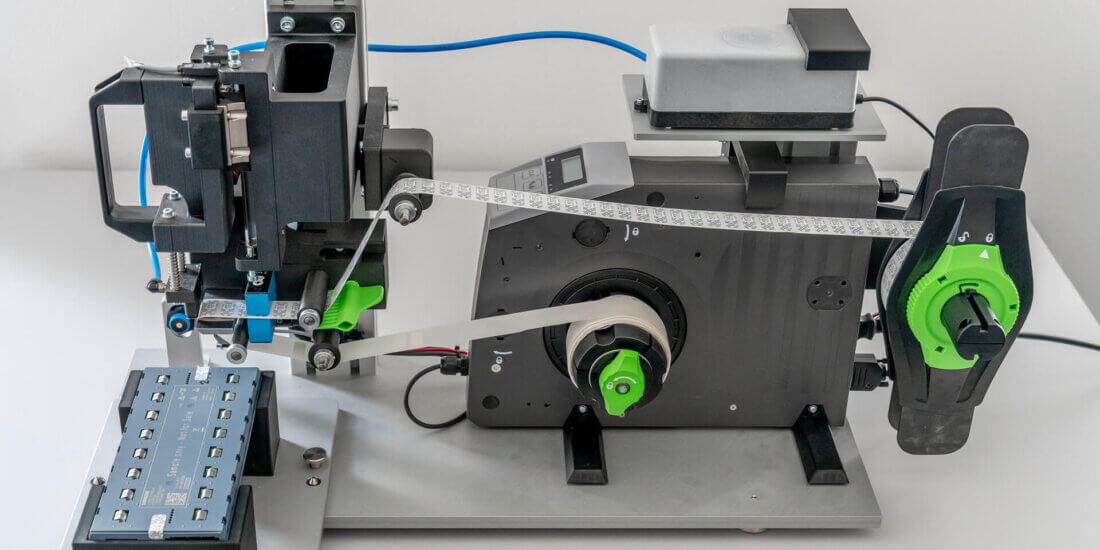

Another advantage of the new unit is automated handling of the Pressure Compensation Seal. While in other assembly processes involving ultrasonic welding the membranes often need to be positioned manually, a precision dispensing system takes care of that in this case. It guides the pre-cut membranes automatically and precisely underneath the sonotrode. That enhances repeat accuracy, reduces operator effort, and minimizes the risk of positioning errors in the current process.

In addition, an airflow measurement unit is directly integrated in the system. Immediately after manufacturing, it checks if the Pressure Compensation Seal reliably performs its job. Together with the sonotrode that needs to do only one job anymore and the automated “travel” of the membranes this has resulted in a solution that constantly guarantees high component quality and process reliability.