High Expertise: Pharma-RFID that Outperforms

The digital transformation is in full swing also in the pharmaceutical industry. Smart and interactive solutions for process optimization, digital tracing, authentication, and patient support are becoming increasingly important. But it takes more than a chip in a label for

Securely Sealed in Freezing Cold

Innovative active ingredients such as mRNA, biologics, or cell and gene therapies not only bring progress—they also place the highest demands on their packaging. The situation becomes particularly critical when drugs are stored and transported at high sub-zero temperatures. In

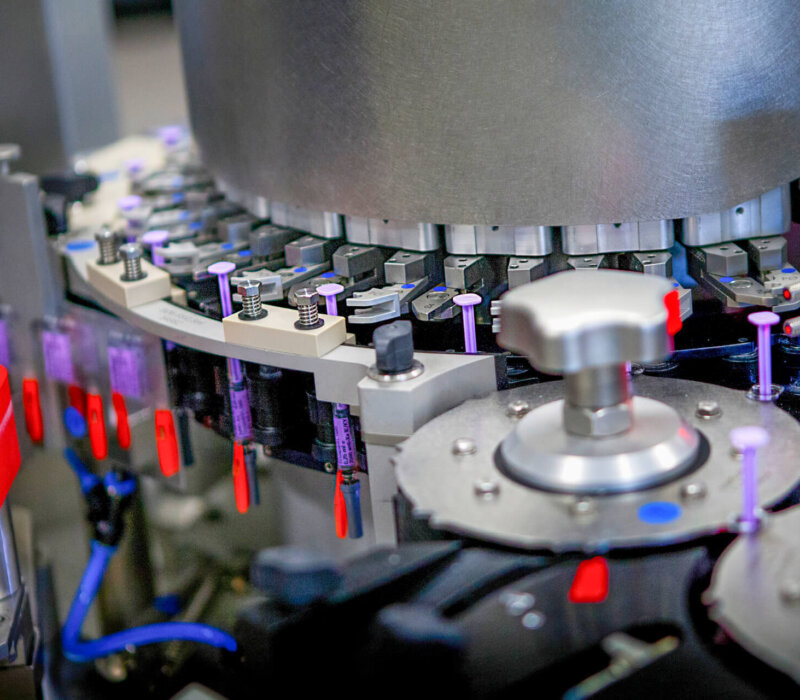

Needle-Trap: Less Material, More Efficiency

Safety for the user, cost efficiency for the manufacturer, and a clear gain for the environment: With Needle-Trap, Schreiner MediPharm offers a unique system for protection against needlestick injuries combining economy and sustainability in a single product—while setting standards.

Together for More Sustainability

United by an ambitious goal: The members of the Alliance to Zero are committed to sustainably reducing CO₂ emissions along the pharmaceutical supply chain—with a view toward compliance with the Paris Climate Agreement. Halfway into the year, the network got

100 US Employees: Location Reaches New Milestone

The Schreiner Group has reached another milestone in the USA: since autumn, the number of employees has reached triple digits. Site Manager Ken Forlenza and his team welcomed the 100th employee, who will now work together with his colleagues, dedicatedly

International Strategy Pans Out

Schreiner Group continues to grow internationally – and one key pillar of this success lies in China. The Jinshan site in the Greater Shanghai area is developing steadily and making an important contribution to the company’s global strength. President and

Dorfen: Systematic Growth

Schreiner Group visibly and noticeably keeps investing in its second German location in Dorfen. The successful completion of the extension of the plant and rollout of the Automated Guided Vehicle (AGV) starts a new chapter for the production location. More

Top Performance: Medium-size Business Award goes to Schreiner Group

A great honor for the international family business from Oberschleissheim: Schreiner Group has been recognized with the 2025 Bavarian Medium-Size Business Award. The awards ceremony took place in a festive setting at the Munich “Künstlerhaus” at the end of July.

Innovation Award for Top-Class Product

At this year’s FINAT Label Competition, Schreiner Group impressed with the Smart Syringe Box from the Schreiner MediPharm business unit. The smart packaging solution specifically for syringes won the first-place award in the “Innovation” category. As part of the European

Connected for Sustainability

The EU Corporate Sustainability Reporting Directive (CSRD) requires many companies to comprehensively report about their environmental and social impact, and corporate governance. The objective is to achieve transparent and comparable sustainability reporting within the EU. To jointly master these requirements,