All-in-One—Multiflexible Precision Dispensing Application System

SCHREINER SERVICES

All-in-One—Multiflexible Precision Dispensing Application System

Many manufacturing companies process different products on the same production line. Specifically for these requirements, the Schreiner Services competence center has developed a dispensing and application system that is able to apply different label versions to diverse products in a reliable process.

Flat, cylindrical, or square. Applying labels to products with such a diversity of shapes on the same line seems to be impossible—but is feasible! The experts from Schreiner Services have developed a suitable precision dispensing application system for this purpose. It enables processing of different label versions with a changeable, tailored applicator—at very high levels of accuracy:

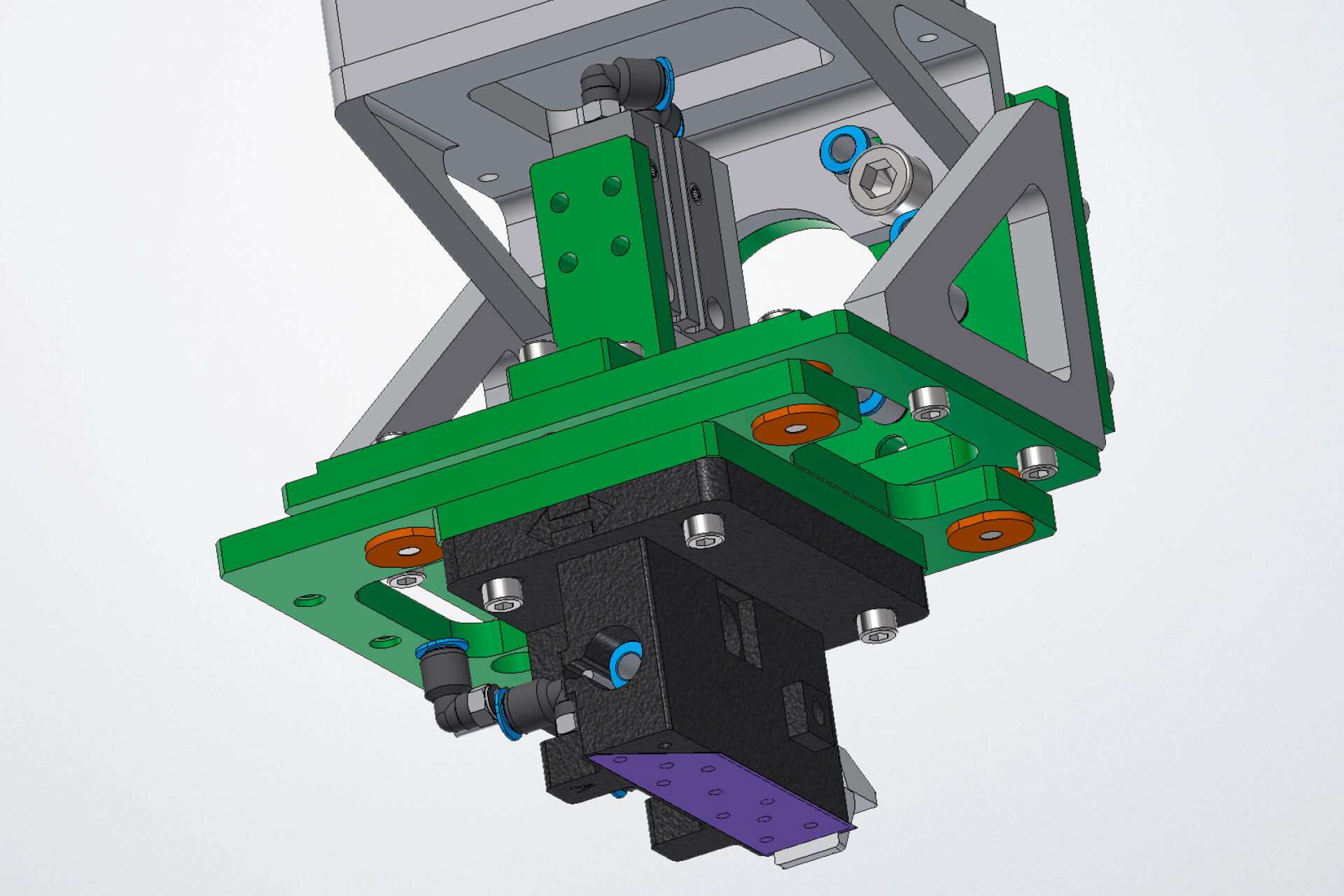

Maximum precision is achieved by a floating bearing arrangement and centering above the workpiece. In addition, the punch is aligned with the product. The dispenser automatically adjusts to changes in label dimensions that are sent to it by a programmable logic controller (PLC).

Different label versions can be processed with a changeable applicator.

A quick-change applicator head with encoding ensures that the right punch is used for the label. An encoded quick-change set for the applicator punch and the PLC-controlled electrical adjustment of the dispensing system to the desired label size serve this purpose, allowing for 120 versions and change sets to be used.

PLC

A programmable logic controller is a device with a programmable memory that is used for controlling a machine or assembly line. In other words, specific functions and workflows can be programmed and implemented.