Advancing into a New World of Wound Treatment

SCHREINER PROTECH

Advancing into a New World of Wound Treatment

Following minor injuries such as cuts and lacerations, the skin quickly repairs itself. However, it does not do so in the case of chronic and large wounds. They often entail a long and painful healing process requiring prolonged medical treatment because not only the affected areas of the skin are damaged but so is the subcutaneous tissue. Together with Schreiner ProTech, Coldplasmatech has developed a flexible wound dressing based on printed electronics that promotes wound healing by means of cold plasma.

Bed and other pressure sores or diabetic foot ulcers are cases in point. While routine dressing changes are necessary, they also mean an ordeal for the patient, each time inflicting a new injury that can delay the entire healing process. “Patients suffer severely,” says Dr. Carsten Mahrenholz, a chemist, biologist and economist, and one of the founders of Coldplasmatech GmbH, a company engaged in mitigating the problem of slow-healing wounds by means of novel cold plasma technology.

Dr. Mahrenholz and his team began their work by thoroughly surveying the wound-healing landscape. The team soon realized that wound dressings are the preferred choice because, among other benefits, they optimally complement existing medical regimens and products. Afterwards, the interdisciplinary team, then still connected to the Leibnitz Institute for Plasma Science and Technology (INP), tackled the challenge of designing a dressing that allowed healing plasma to be generated directly at the wound surface.

Cold plasma presents a promising hope for patients with chronic, poorly healing wounds. The INP scientists’ research showed that cold plasma can efficiently kill bacteria and even effectively combat the type of dreaded antibiotic-resistant pathogens common in hospitals and hospice settings. Cold plasma acts by purely physical processes, attacking the microbes’ cell membranes, among other targets.

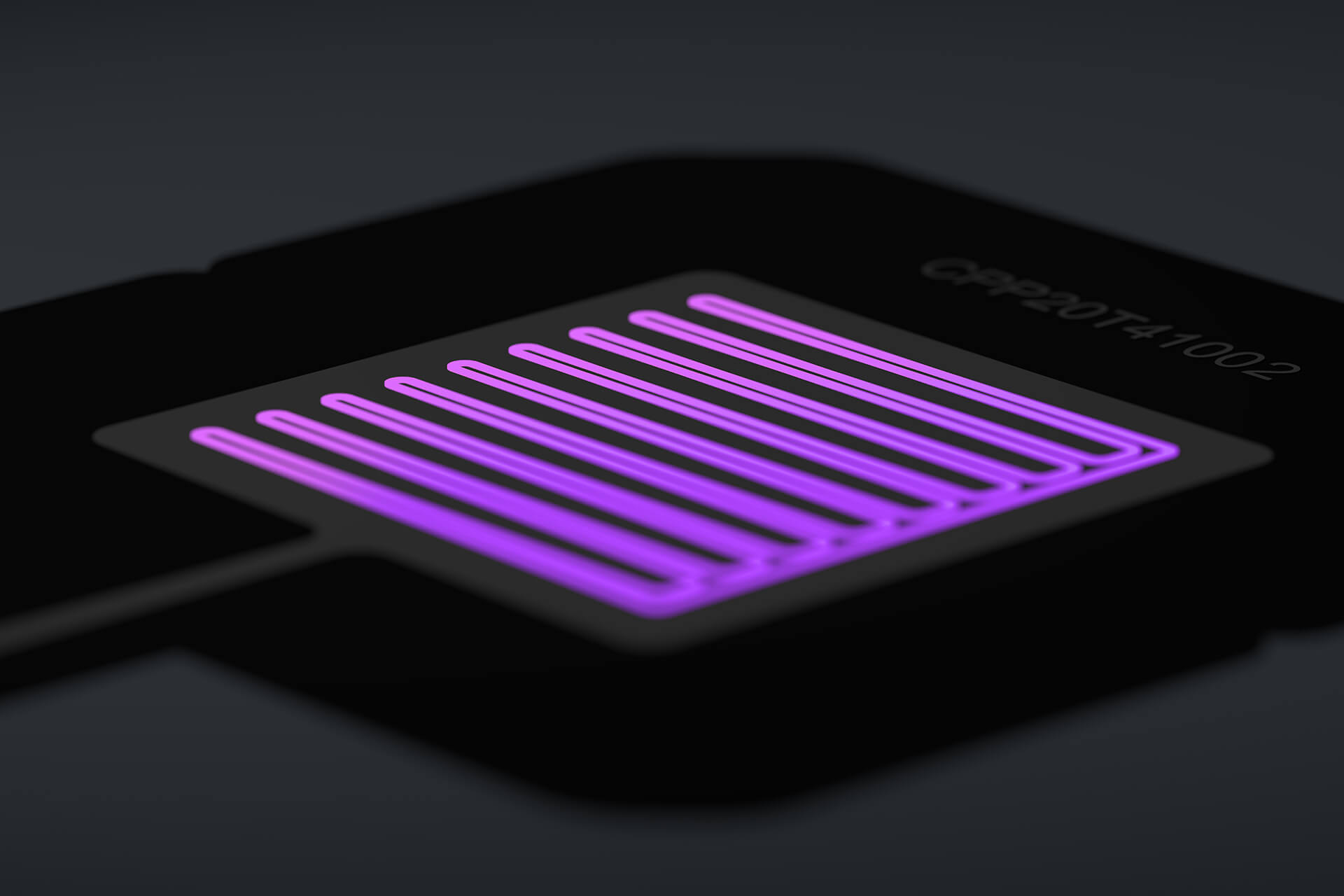

Recognized by its signature glow, cold plasma is a natural phenomenon that, until now, had not been applied to a wound-healing setting. Plasma forms, for example, when a gas passes through strong electric fields that dissociate its electrons from their molecules. The gas becomes electrically conductive and shimmers with a purplish hue. Dr. Mahrenholz and his team were convinced that cold plasma could heal. Using silicone technology, the scientists worked toward developing a new wound dressing solution that creates and applies high-energy gas directly to damaged skin—destroying bacteria while stimulating the body’s self-healing powers.

Joint development for fast wound healing

Flat Wound Dressing with Printed Electronics

The result was a flexible device called CPTpatch, a flexible system in a line of wound dressings drawing on a plasma power source called CPTcube. “We needed something lighter, more reproducible, and more user-friendly,” said Dr. Mahrenholz. Coldplasmatech turned to film solutions expert Schreiner ProTech, whose engineering team developed a customized Electronics-in-Film (EIF) solution for the next generation of CPTpatch. Key to the effort was the incorporation of specialized printed electronics.

The requirements were several: a flexible conductor track structure was needed for the wound dressing and the application had to withstand several thousand volts from the CPTcube power source without causing electric shock. High precision in printing and die cutting were other key criteria—a need that can sometimes conflict with manufacturing simplicity. Here, Schreiner ProTech determined ideal materials suitable for both medical application and production efficiency.

The second CPTpatch iteration incorporates a conductor structure made of a film composite capable of generating cold plasma. To ensure optimal adaptability to the parameters of various wound dressings, it comprises several Joint development for fast wound healing functional layers including films, fully printed electronics, an insulating layer, and adhesives. The result is a solution that achieves the original CPTpatch’s wound-healing abilities with less space, less electric voltage, and less production complexity.

“With Schreiner ProTech and the PrinTronics competence center, Coldplasmatech has gained the support of a real expert in the field of printed electronics,” says Dr. Carsten Mahrenholz, founder and CEO of Coldplasmatech GmbH.

Die zweite CPTpatch-Iteration integriert eine Leiterbahnstruktur aus einem Folienverbund mit der Fähigkeit, das Kaltplasma zu erzeugen. Um eine optimale Anpassbarkeit an die Parameter unterschiedlicher Wundauflagen zu gewährleisten, umfasst sie mehrere Funktionsschichten einschließlich Folien, vollständig gedruckter Elektroden, einer Isolationsschicht und Klebstoffen. Dadurch entsteht eine Lösung, welche die Wundheilungsfähigkeiten des ursprünglichen CPTpatch mit geringerem Platzbedarf, geringerer elektrischer Spannung und geringerer Fertigungskomplexität realisiert.

„Mit Schreiner ProTech und dem Competence Center PrinTronic hat Coldplasmatech die Unterstützung durch einen echten Experten im Bereich der gedruckten Elektronik gewonnen“; erklärt Dr. Carsten Mahrenholz, Gründer und Geschäftsführer der Coldplasmatech GmbH.