Acute Care: Every Second Counts!

SCHREINER MEDIPHARM

Acute Care: Every Second Counts!

Wailing sirens, flashing blue lights, and a medevac helicopter hovering above the scene: In the event of an accident involving potential loss of lives, the victims require immediate medical attention. For first responders, paramedics, and emergency room physicians, this means having to make decisions and taking action in a matter of seconds. Errors must be avoided at all costs, especially concerning medications, because they can threaten the patient’s life. In such scenarios, medications with clear markings and first-opening indications are particularly helpful for medical personnel. Schreiner MediPharm’s marking solutions specifically for acute care, emergency medicine, and for optimizing hospital supply chains can help administer life-saving medicines fast and safely.

Acute care encompasses all emergency medical services—from first aid, rescue ambulance services, admission to the emergency room and surgery, to treatment in intensive care units. In all of these settings, medications have to be administered as efficiently as possible without jeopardizing the patient’s safety due to potential medication errors. Equally important is a transparent and reliable hospital supply chain ensuring that the right medicine is available at the right time.

Several trends are emerging in this context: Prefilled syringes are increasingly being used instead of vials to enable fast injections. Modern, high-grade COC/COP syringes are progressively replacing disposable plastic syringes. More and more automated RFID-based inventory management systems are rolled out for simplified administration and reliable processes.

To enable pharmaceutical manufacturers to satisfy these acute care requirements, Schreiner MediPharm offers functional labels and marking solutions with analog and digital features specifically for emergency medicine uses.

All solutions are customized to suit the relevant acute care application—so that medications are administered fast and safely to emergency and intensive care patients.

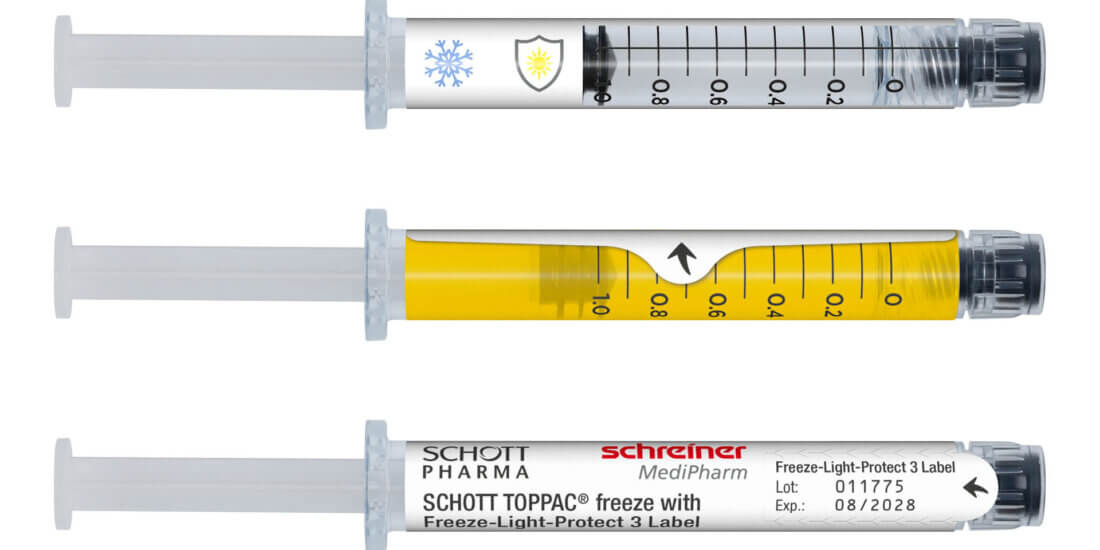

First-Opening Indication and Integrity Protection of Prefilled Syringes

Cap-Lock

A cap adaptor is attached precisely to the primary closure of a syringe, followed by the application of a label with an integrated perforation that wraps around the syringe body and the bottom part of the adaptor. While opening the syringe cap the label is partially destroyed and irreversibly indicates that the syringe has been opened.

Syringe-Closure-Wrap

A marking solution where the label wraps around the syringe body and the cap. Pulling off the upper part of the label triggers the first-opening indication feature and a warning message emerges. In addition, security cuts destroy the label so that it cannot be closed again unnoticeably.

These Solutions Offer:

- Reliable tamper protection from syringe production to drug delivery

- Reduced hospital storage capacity requirements: no secondary packaging/ blister packs required

- Adaptable to many common syringe sizes

- No impairment of the prefilled syringe in production and label application

- Application without heat (unlike shrink solutions)

- Optional availability of digital firstopening indication via RFID

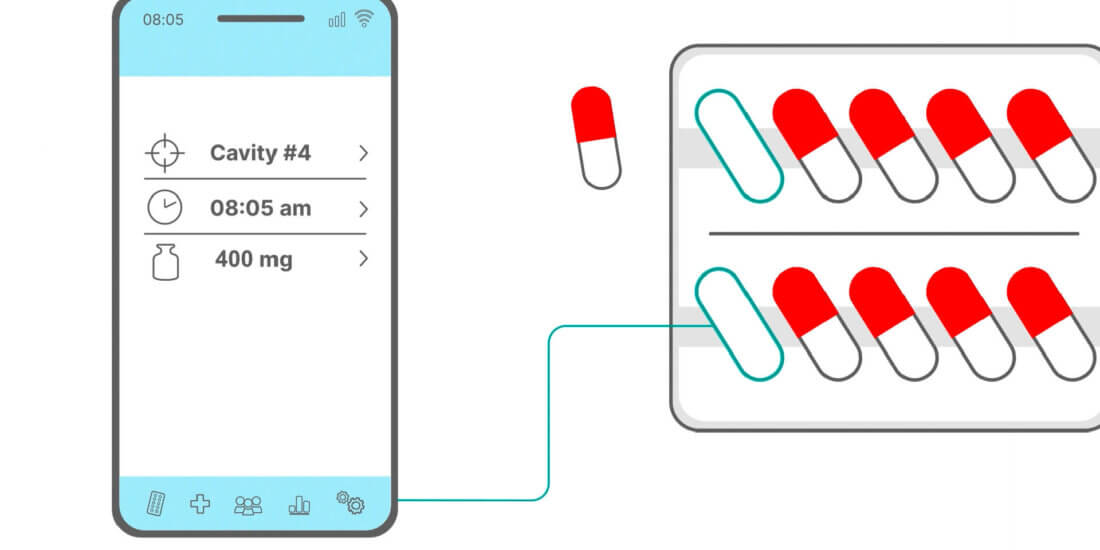

Automated Inventory Management

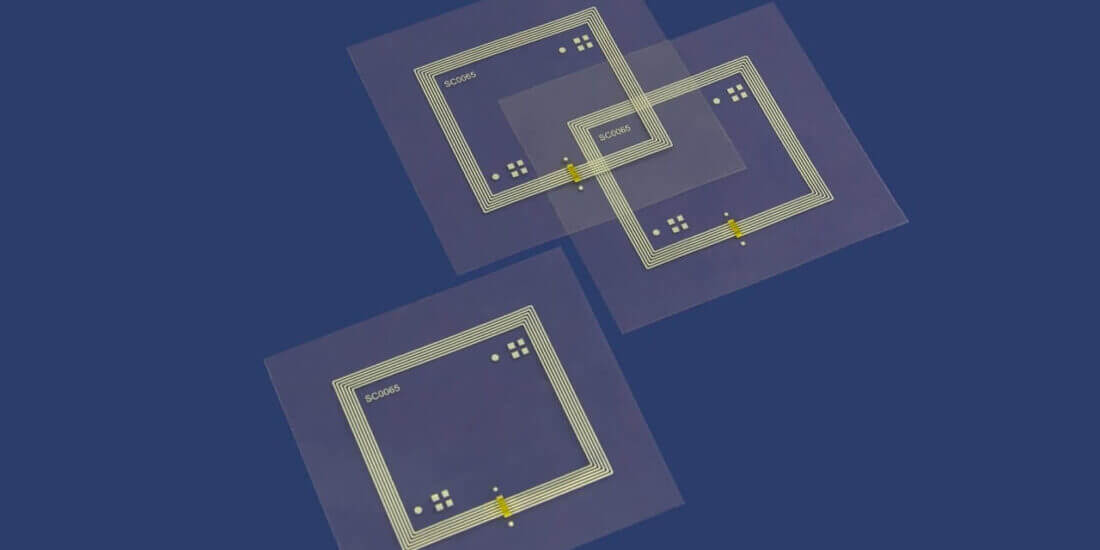

Robust RFID-Label

The label contains an integrated RFID chip for contactless reading of vials and syringes on unit level. The RFID transponder is secured by a special protective structure that absorbs mechanical impacts and effectively protects the chip against damage.

Cap-Lock plus RFID

The digital evolution of the analog Cap-Lock cap adaptor label combination. The RFID chip is embedded in the upper part of the label at the level of the cap. As a result, it is largely located outside the liquid-filled area so that the liquid does not interfere with the UHF RFID chip’s readability.

These Solutions Offer:

- Reliable reading and long read range

- Digital proof of integrity

- Precise adaptation to small containers with narrow radii

- Compatibility with polymer syringes

- Compliance with the standard for RFID healthcare solutions developed by DoseID

Migration Risk Minimization and Barrier Protection for COC Syringes

Labels with special barrier functions

Functional labels can enhance polymer syringes and minimize migration risks. Based on the requisite extensive know-how in materials, inks, and more, the labels can be customized to suit the specific application. The compensatory barrier functions of the functional labels for polymer syringes were demonstrated in a 2019 joint study with SCHOTT.

These Solutions Offer:

- Reduction of the syringe’s oxygen diffusion

- Prevention of adhesive, material and ink migration into the drug

- Resolution of the reduced barrier properties of COC syringes vs. glass syringes