Pressure Compensation Seals for Venting

SCHREINER PROTECH

Pressure Compensation Seals for Venting

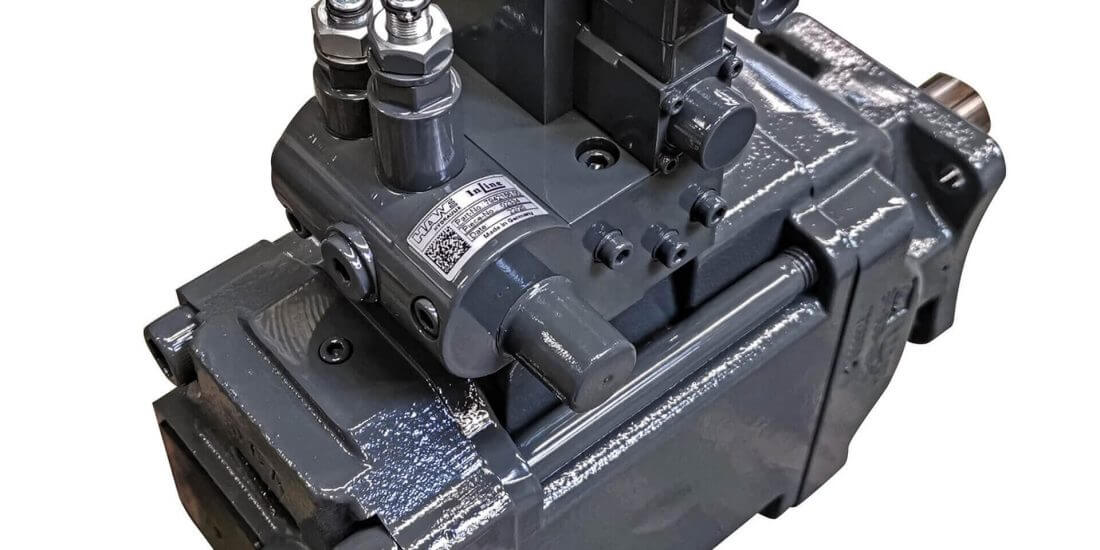

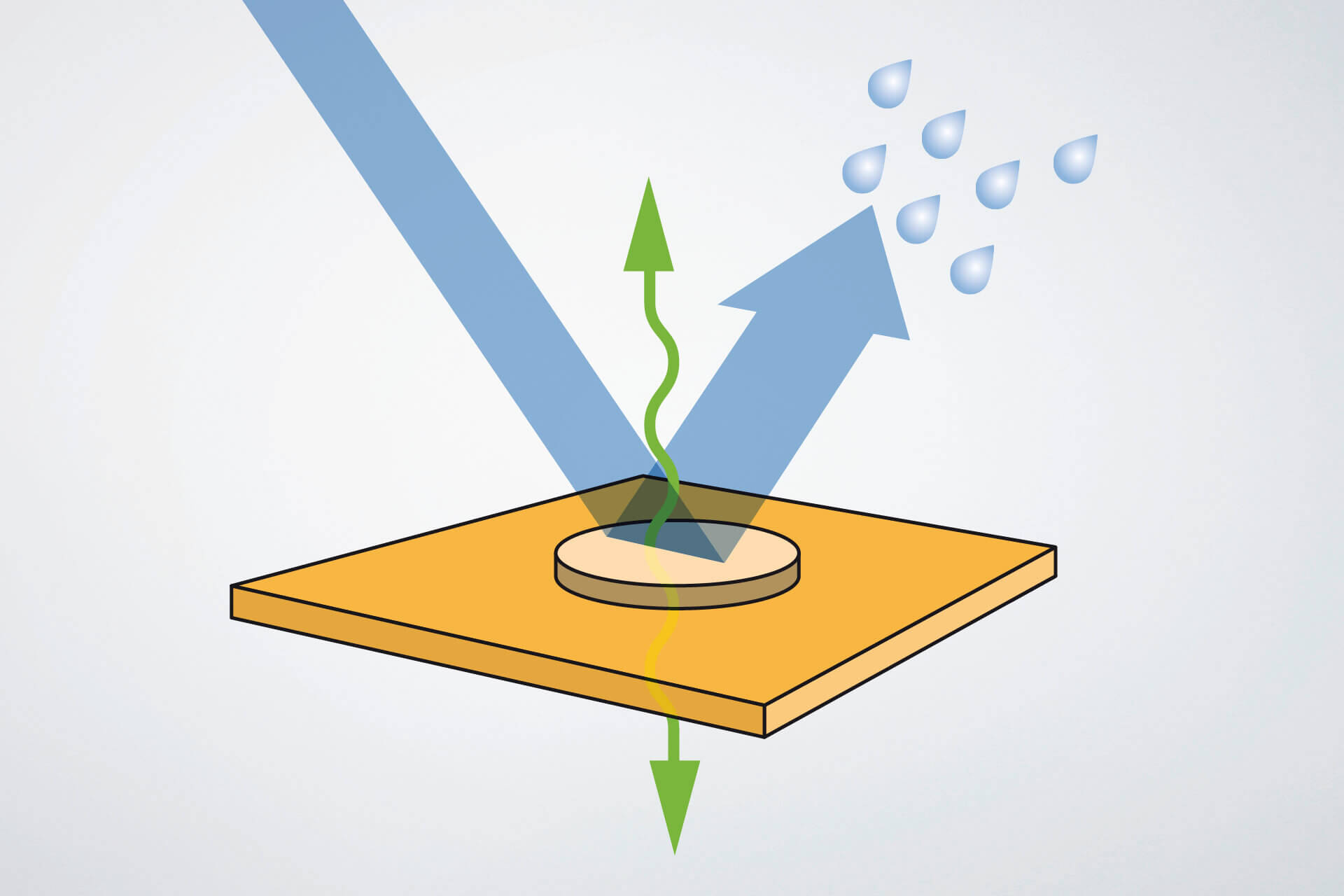

Excess pressure or vacuum caused by temperature fluctuations can deform housings and lead to leakage. Pressure compensation seals from Schreiner ProTech equalize pressures and protect housings and components. They are both gas-permeable and watertight. Schreiner Group has been working with this proven technology since 1997, now producing volumes of tens of millions per year. The membranes prevent pressure differences from occurring inside a housing and therefore increase the service life of electronic components.

Pressure Compensation Seals in the Field

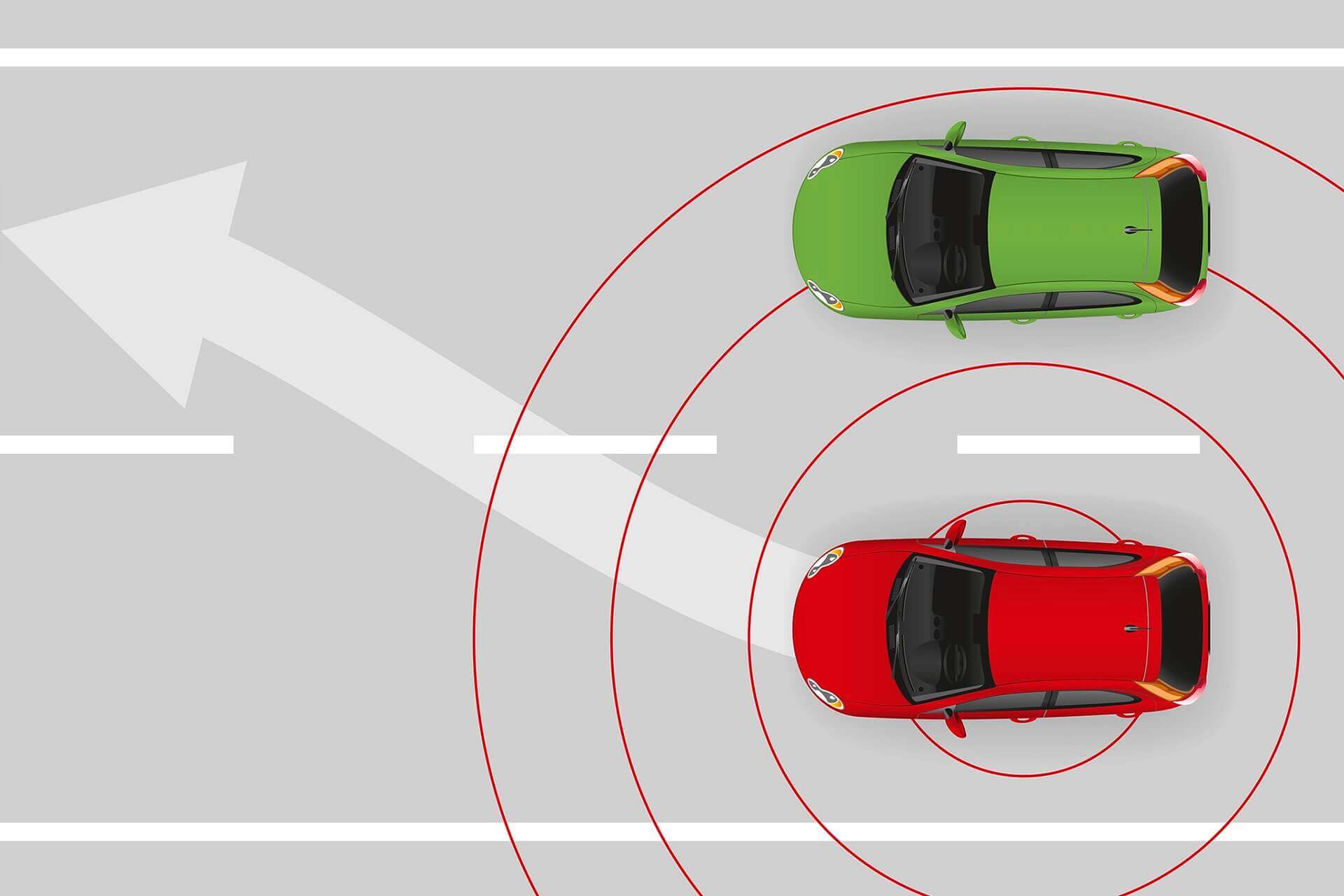

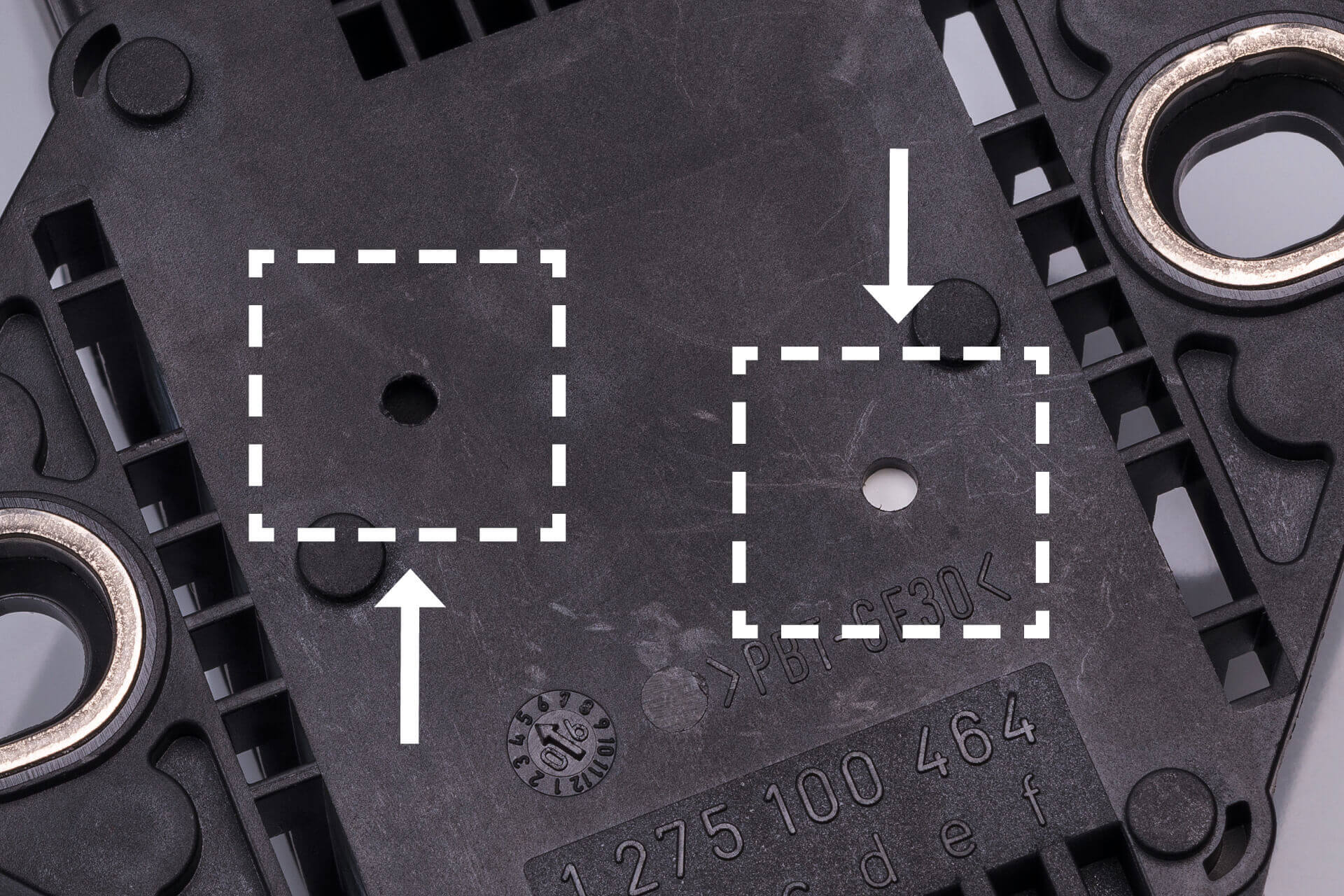

Radar Lane Change Assist

Due to the blind spot, any lane change while driving entails an accident risk. To minimize this risk, modern cars are equipped with radar lane change assist systems warning drivers while steering or using a turn signal of obstacles in immediate proximity to the chosen direction of travel. Pressure compensation seals from Schreiner ProTech ensure reliable venting of the electronics in radar lane change assist systems.

Pressure Compensation Seal in Nameplate

In many cases, housings require both protection and marking. However, several products and process steps slow down the production process and result in a higher defect rate. For the sensor housing of a driverless transportation system at SICK AG, Schreiner ProTech developed a nameplate with an integrated pressure compensation seal.

Pressure Compensation Seals with Value-Adding Benefits

Heavy-duty: PCS High Protect

Harsh ambient conditions frequently prevail in general industrial settings, where pressure compensation seals have to meet higher requirements for steam jet resistance and mechanical protection. For these purposes, a combination of pressure compensation seals and steam jet-resistant film is used: PCS High Protect combines very low design height with maximum protection against mechanical stress.

Unobtrusive Design: Black Membrane

A black membrane has been qualified specifically for use on black housings. While the pressure compensation function is performed unobtrusively and hardly noticeable visually, dirt or dust particles are less conspicuous on a dark pressure compensation seal than on a white PCS.

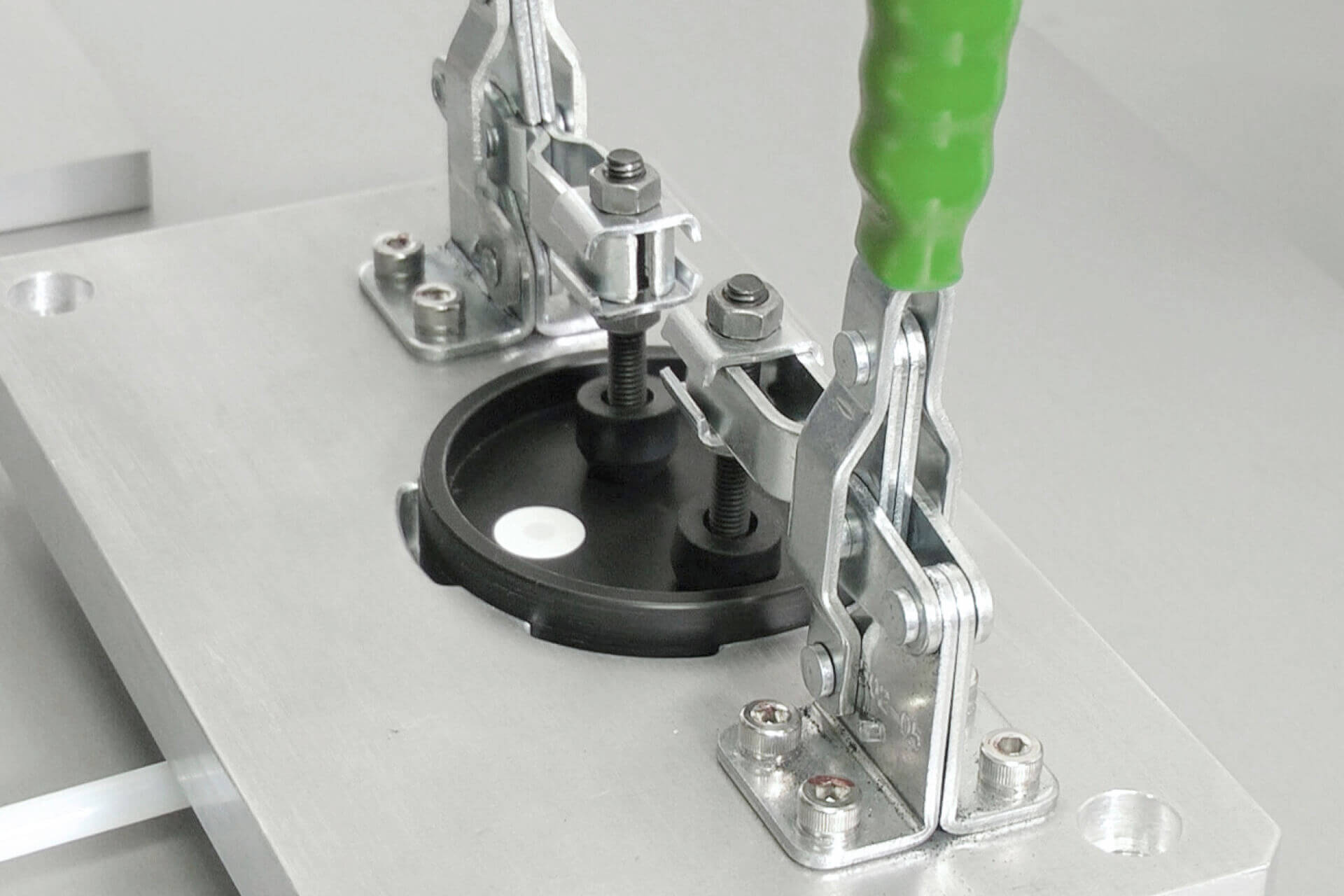

Application System for Process

Stability: Ramp-up Service Pressure compensation seals are hightech products that will deliver perfect performance only after precise application to the components on the assembly line. This can be achieved exclusively by using an application system adapted to the pressure compensation seal and all process parameters, and incorporated in the assembly line so as to ensure process stability.