Tamper Protection for Tachographs

SCHREINER SERVICES

Tamper Protection for Tachographs

Tachographs are indispensable for the transport industry—and their tamper-proof nature is a crucial factor for integrity and efficiency. The experts from the Schreiner ProTech business unit, together with the specialists from the Schreiner Services Competence Center, have now developed an innovative and customer-specific solution for the Scandinavian branch of the renowned American manufacturer Stoneridge that offers exactly this and thus makes the logistics industry safer.

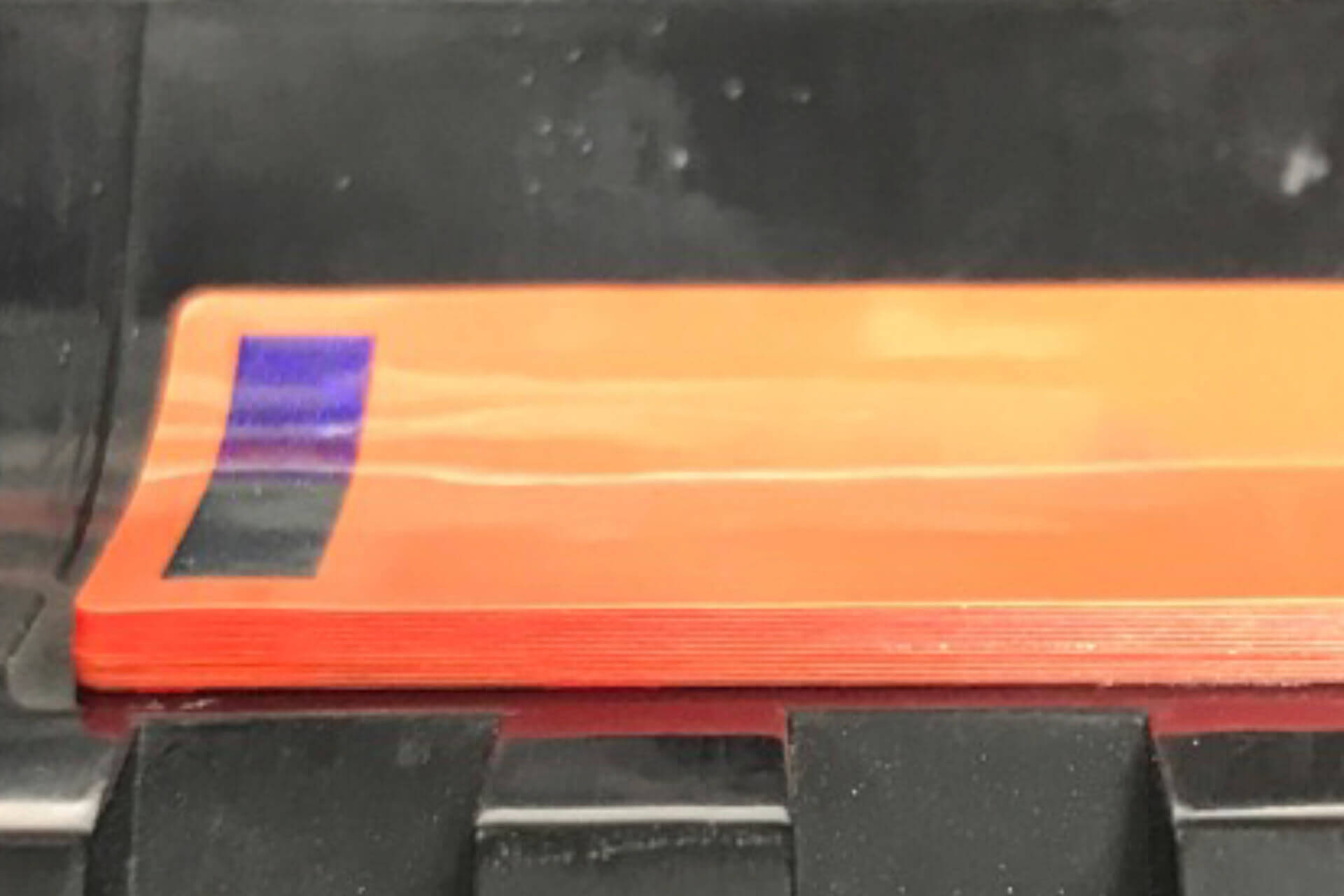

Actually, the task sounded quite simple: the application of a seal to the plastic surface of two halves of the case to prevent manipulation. But often it is the supposedly simple things that turn out to be particularly challenging. “In contrast to conventional, flat surfaces, the seal should be applied to a housing in a hard-to-reach and bent area,” explains Michael Reineke, Head of the Schreiner Competence Center Services. The team’s ambition was awakened, especially since the customer wanted to fundamentally optimize the previous, purely manual and process. The goal: improved speed and, above all, significantly higher process reliability.

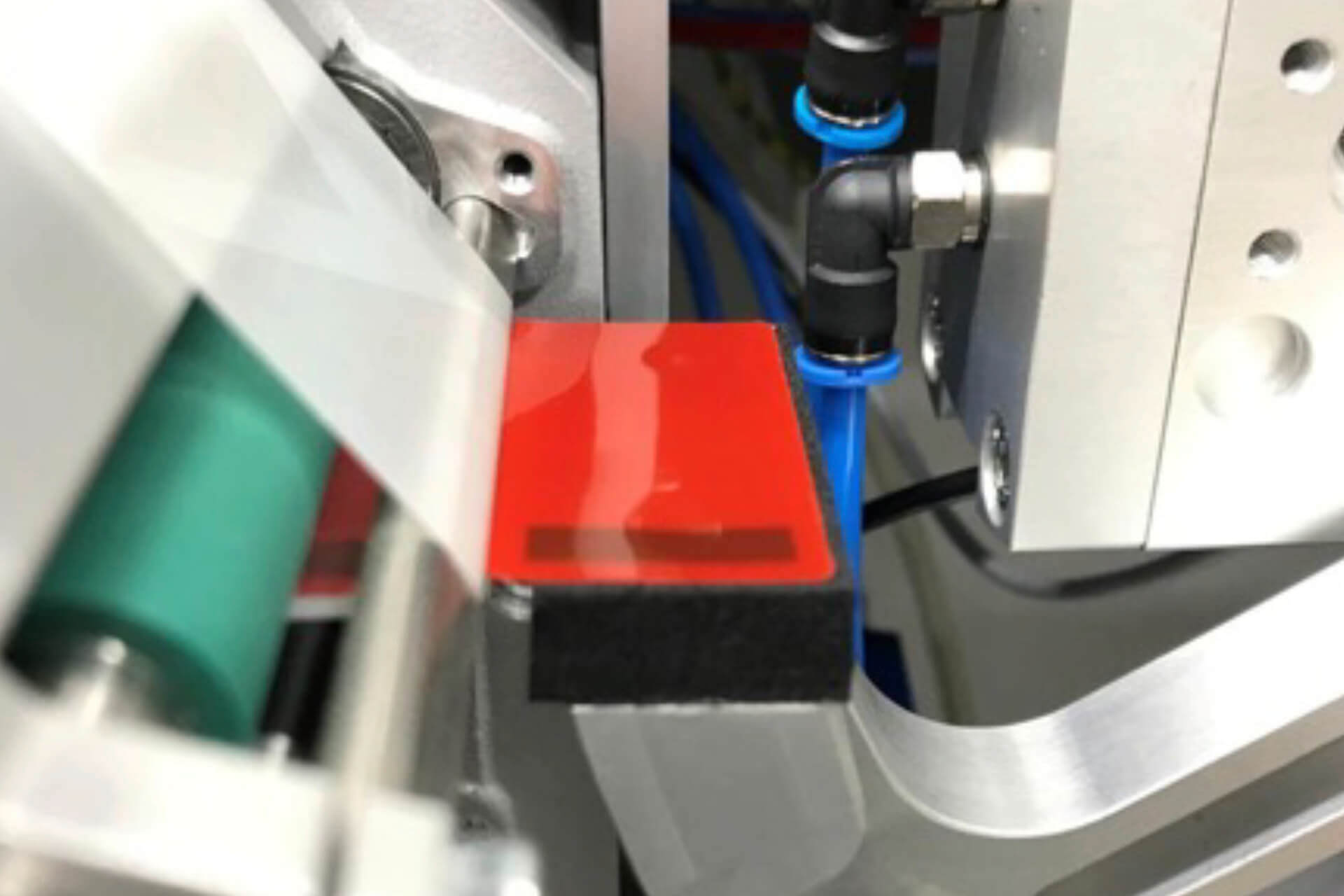

To achieve this, Schreiner Group’s experts took a two-pronged approach: The development managers took care of the seal, which was equipped with various security features, in a great deal of detailed work and precise coordination, while a few rooms away they had to design an applicating machine for this special case. The material of the ink pad, which presses the seal, played just as much a role as the rotary movement required by the application angle.

It took just under half a year before the tailor-made solution was ready. The result: the fast, precise and reliable application of an individual security seal. The seal, which had to be approved in accordance with the test rules of the Federal Office for Security (BSI), now forms a complete solution in combination with the machine. “For us as a manufacturer,” explains Thomas Anderson, project manager at Stoneridge Electronics, “it is of great importance that our products enable absolutely precise monitoring of driving and rest times—and this solution makes our SE5000 even smarter. What certainly contributed to the successful implementation of the project was the trusting cooperation with all those involved at Schreiner Group and the professional customer relationship.”

The very simple order developed into an interplay of expertise and innovation, with which Stoneridge can not only strengthen its position in the market, but now also set new standards for safety and efficiency in the transport industry.