The Right Twist for PCS: Torsional Ultrasonic Welding

SCHREINER PROTECH

The Right Twist for PCS:

Torsional Ultrasonic Welding

Longitudinal ultrasonic welding systems are a time-tested technology not only for joining membranes. However, up until now, only self-adhesive versions have been usable for fleece-backed membranes with high airflow. Those days are over now:

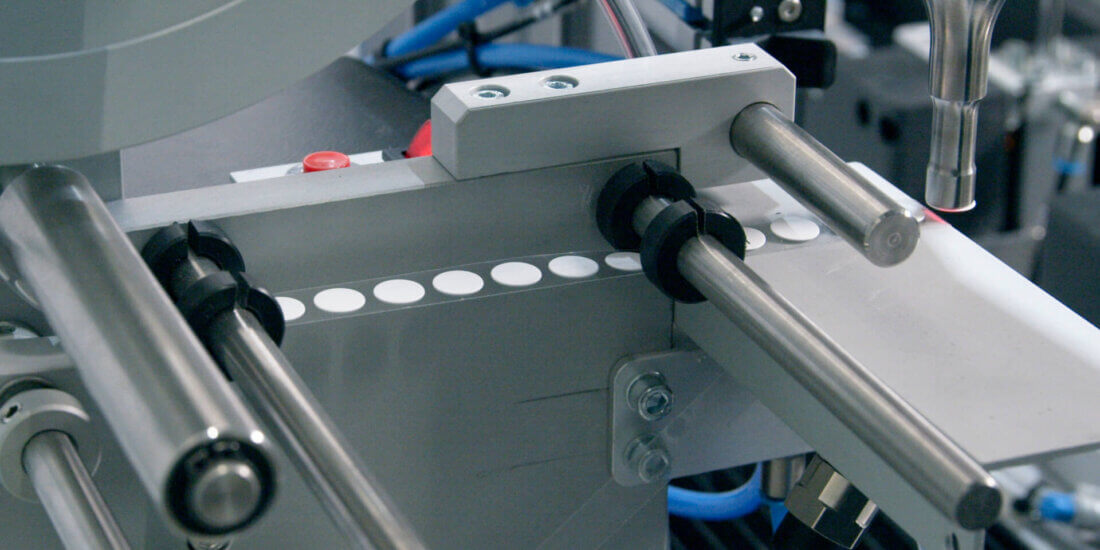

In a pioneering joint project, the team from Schreiner ProTech together with MS Ultraschall Technologie GmbH developed an innovative ultrasonic welding system for mechanically sensitive pressure compensation seals (PCS). The machine has clear advantages: high speed and precision.

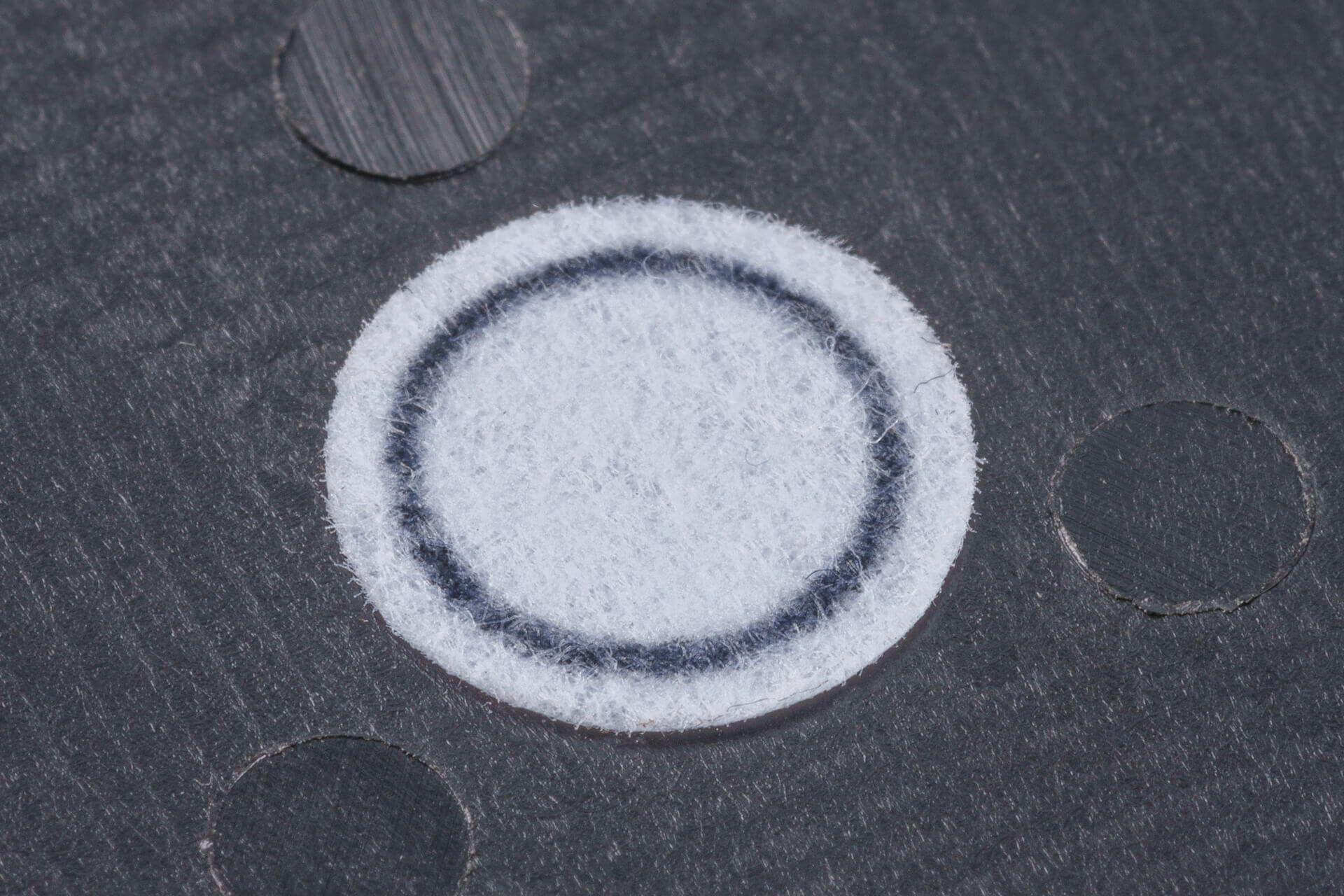

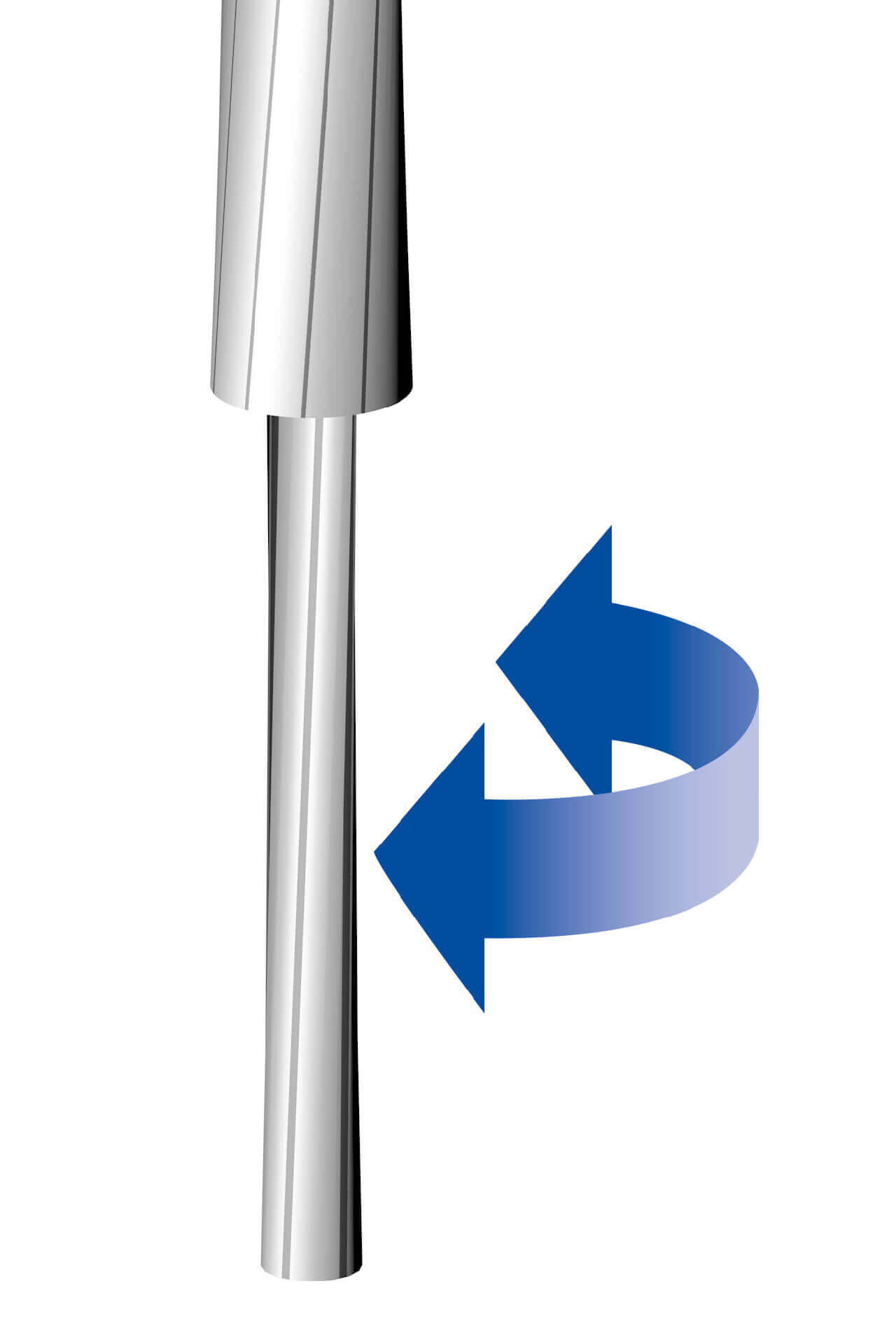

In less than two seconds, the PCS sits exactly where it should. Plus, a quickchange system for tools significantly reduces production costs as well. Product Manager Adrian Marggraf is more than happy: “The basic machine is a development by MS Ultraschall while the expertise in ultrasonic membrane welding was provided by Schreiner Group’s Technology and Innovation Management (TIM) team. This project combines the professional knowledge of both parties and together we can now offer our customers an allnew all-in-one solution.” That solution is nothing short of a small revolution: Unlike longitudinal ultrasonic welding, a process in which the energy is transmitted directly in one direction, the torsional technology features indirect energy transmission through a rotary motion around the welding seam axis. That method is particularly gentle and specifically suited for mechanically sensitive membranes with high airflow. The benefits are obvious: “Especially in the automotive sector, where the components with sensitive electronics are becoming increasingly smaller and compact,” explains Marggraf, “they need proper pressure compensation.”

PCS attachment using torsional ultrasonic welding not only ensures a totally precise and extremely durable connection but also means that you may only need one high-performance membrane with high airflow instead of several classic PCS.”

Torsional Ultrasonic Welding

- Novel: Suitable for fleece-backed high-performance membranes with high airflow

- Precise: Reliable and precise joining of the component and pressure compensation seal

- Durable: Resists harsh conditions and is ideally suited for industrial applications

- Gentle: Avoids burn-through, perforation, or fraying of membranes

- Efficient: Reduces production costs thanks to fast cycle times and flexible adjustment options

In less than two seconds, the PCS sits exactly where it should.

Consequently, the complete package of the material and machine available from Schreiner ProTech is ringing in a new era of efficiency and quality enabling customers in the automotive engineering industry to benefit not only from a technological advantage but also from a sustainable competitive edge.