Transformation Calls for Close Exchange

SCHREINER GROUP

Transformation Calls for Close Exchange

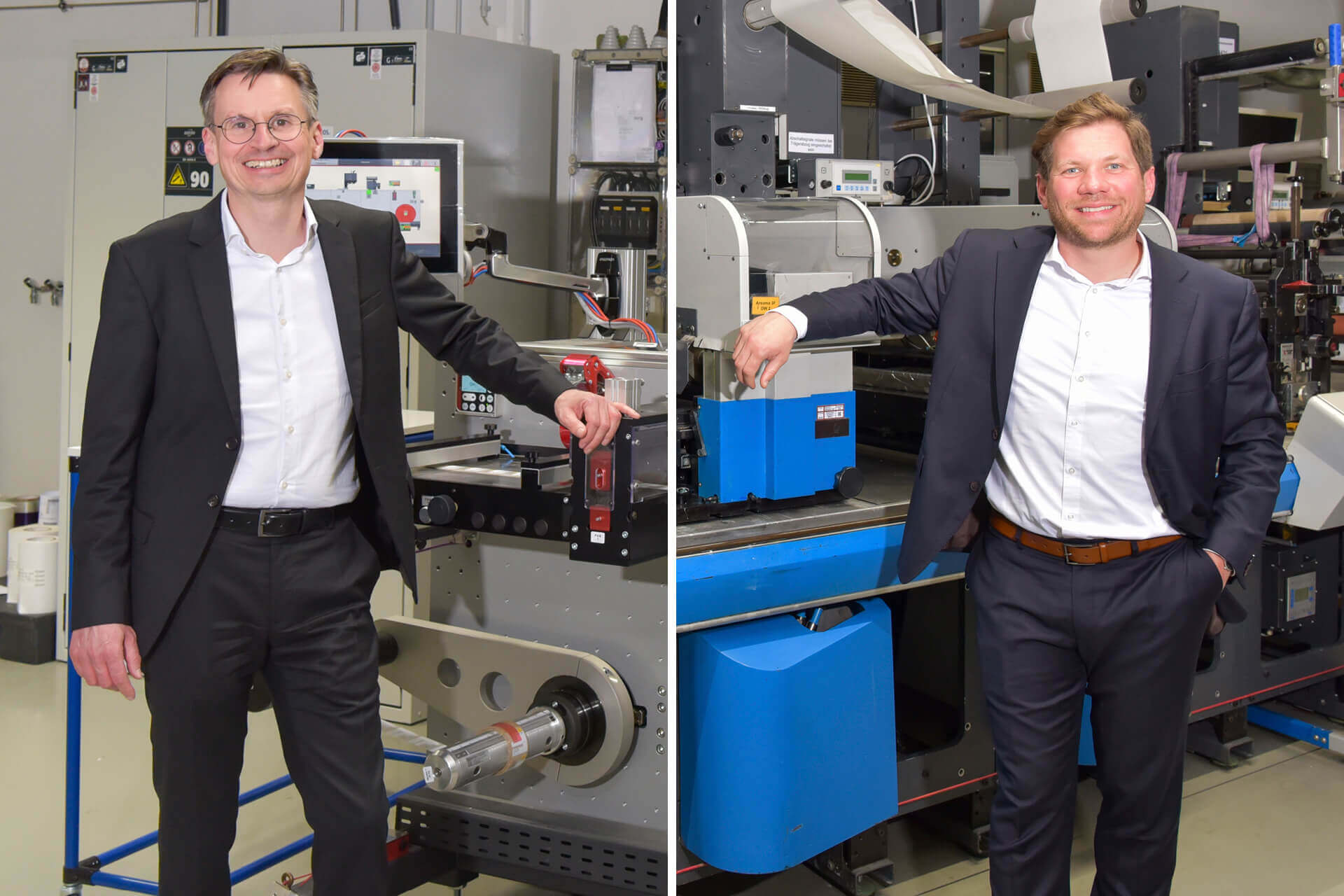

Because Schreiner Group is regarded as a showcase in terms of sustainability TECHNIK+EINKAUF trade magazine published an extensive interview with Dr. Jens Vor der Brüggen (head of research + development) and Christoph Thurl (head of purchasing) in its September issue. Both are deemed to be experts in sustainable changes of material in the spirit of the circular economy while ensuring supply reliability. With permission by the editorial team, we publish an extract from the technical interview focused on the PFAS ban, supply crisis, transparency, and transformation of supply chains.

A PFAS (PFAS is an abbreviation for per- and polyfluoroalkyl substances.) ban is pending, albeit with exceptions yet to be defined. What has been your experience with swapping materials and supply sources in the past?

Thurl: We’ve always had to respond to environmental issues, regulatory conditions, and substance bans. These material and portfolio changes illustrate the effective collaboration between purchasing, development, sales, and quality management. All relevant interfaces are involved in the swapping of materials.

Vor der Brüggen: The PFAS ban is a strategic issue for us. That said, even ten years are not a really long period for developing completely new materials. In the case of new materials, the right teamplay is of paramount importance.

What innovative content stems from the sourcing market, and what content stems from you?

Vor der Brüggen: Our products are created by the intelligent combination of various technologies and from constructive solutions. That’s why we always originate the lion’s share of innovative content.

How did Schreiner experience the supply crisis?

Thurl: Like many companies, we were heavily affected. Even so, we managed to keep our on-time delivery performance at a good level across the board due to our professional crisis management. The relations with our suppliers in a spirit of partnership and our preferred supplier strategy paid off. The rating in our supplier pyramid is linked to rights and obligations. One of the requirements is maximum flexibility in crisis situations.

Did alternative materials occasionally work better than previous ones?

Vor der Brüggen: Technologically, the difference wasn’t that big in most cases. Even so, we wouldn’t have been able to get customer approvals for those changes under normal circumstances. We supply to very sensitive industries. However, I could imagine that due to the recent positive experiences, changes may be easier to assert in the future. For cost reasons, for reasons of sustainability, or to secure the supply chain.

Changes of material require the right teamplay, and we’re very good at passing the ball to each other.

Has transparency increased in the supply chain?

Thurl: In terms of disclosing the supply chains, our industry tends to be restrictive because the supply chains contain a lot of know-how.

Yet the transformation of the supply chains calls for transparency. How do you deal with that? Schreiner intends to become climate-neutral by 2030.

Vor der Brüggen: That’s right. By the end of 2023 we want to achieve climate-neutral production and become climate-neutral by 2030– including Scope 3. That’s an ambitious goal, but we’re making very good progress. We’ve been buying green electricity for ten years and are now switching our heating energy completely to heat pumps. That no doubt makes us a pioneer.

Where do you stand in terms of Scope 3?

Thurl: In the first stage, we need transparency about the emissions and ethical aspects in our supply chains. Starting in 2024, we’ll be subject to the Due Diligence in Supply Chains Act. Via Integrity/Next, we’re currently setting up a solution to generate this data from our suppliers.

Vor der Brüggen: Based on secondary data, we started investigating the product carbon footprint as far back as seven years ago. As a result, we’re in a very good position of showing our customers how much CO2 they’re saving with a product containing recycled materials compared to a standard product. On that level, we already have very high transparency.

Long-term and stable availability of raw materials considering global challenges is currently our core business.

What are the next steps?

Vor der Brüggen: Acquisition of primary data is the big challenge across the entire supply chain. We cannot create that transparency on our own. It’s still going to take a few years before the industries have reached a point at which the CO2 levels are comparable and we have a comparable standard. This requires an exchange between organizations, industry associations, and a harmonized database.

Publication in Leading Magazine

TECHNIK+EINKAUF is the leading publication for all decision makers involved in the industrial sourcing process. It primarily addresses technical and strategic buyers, design engineers, production professionals, and CEOs. The print issue is published six times per year—in September, the extensive interview with the representatives of Schreiner Group was published on four pages.