Small Helper, Big Impact

SCHREINER LOGIDATA

Small Helper, Big Impact

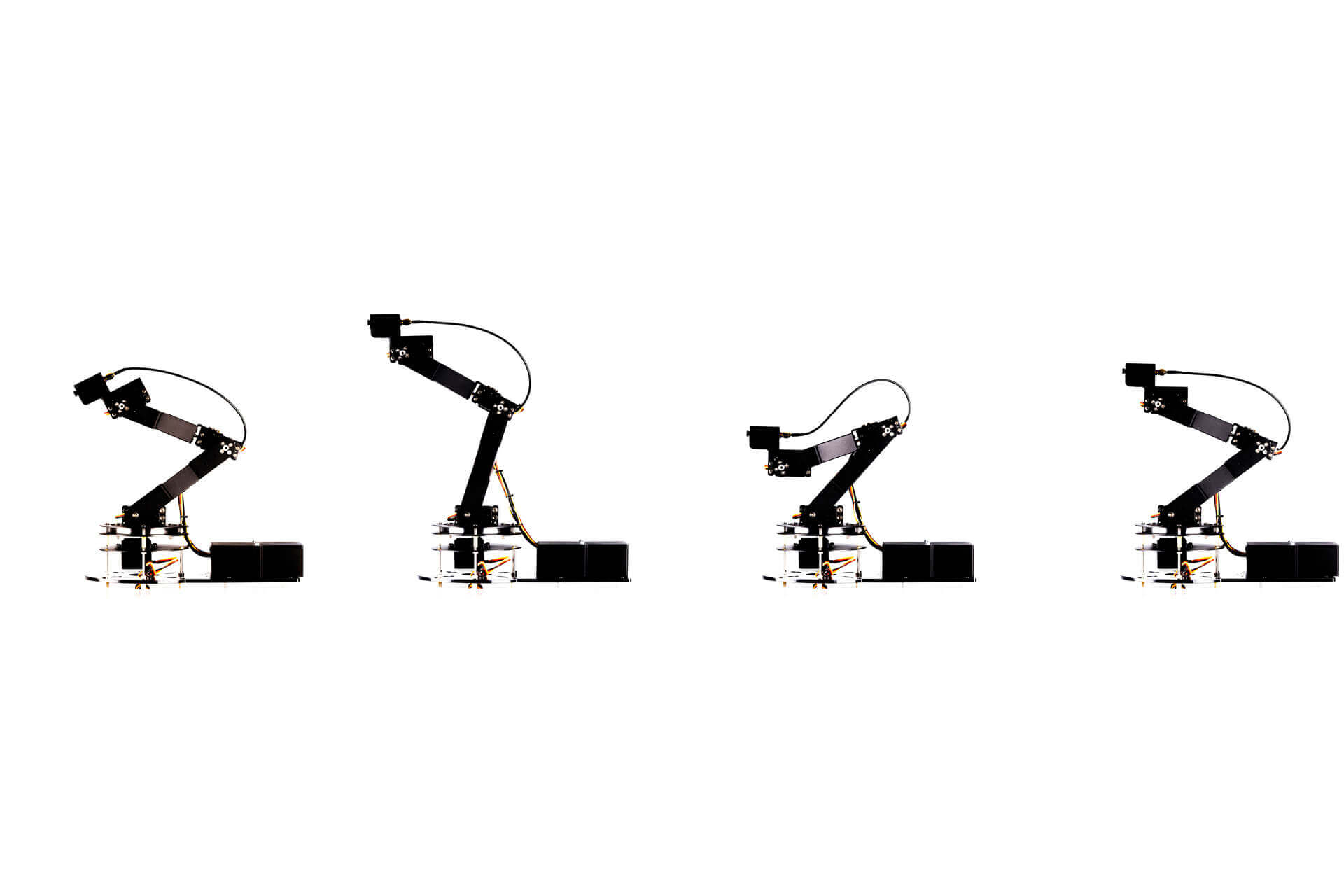

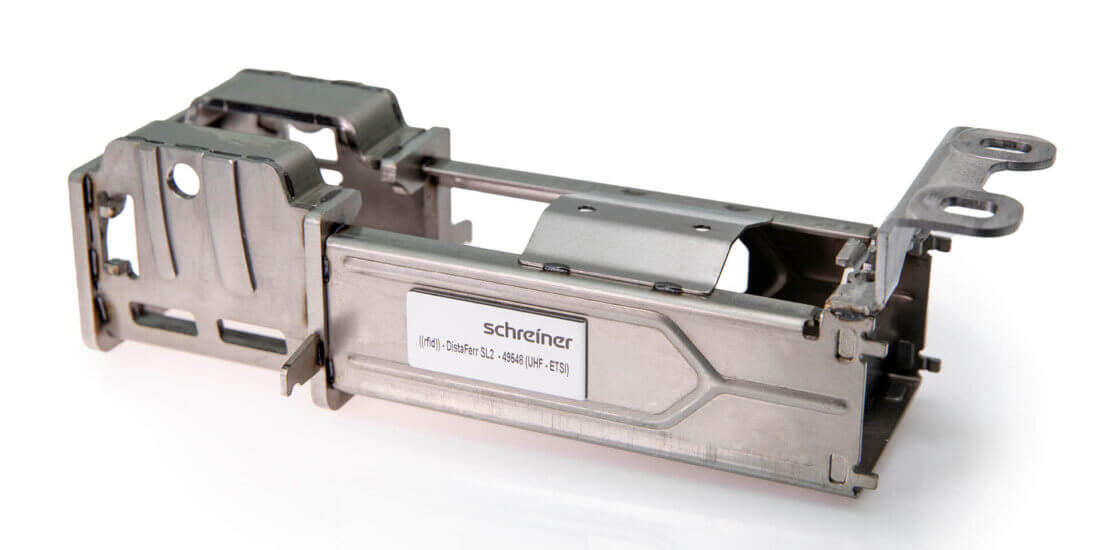

The Schreiner LogiData competence center stands for innovative, customized RFID developments. Now the experts have designed something for themselves—of which customers of course are ultimately going to benefit. The team has had a small specialized helper since this year: 3DM, a fully automated 3D measuring robot assists the developers in measuring the radiation pattern of RFID inlays.

There’s a little bit of jerking at the beginning but then the measuring robot’s arm starts moving smoothly and, following a defined route, keeps sweeping across the RFID chip placed on a rotary plate. All that is happening in a nearly silent and highly precise way. “The robot’s arm doesn’t get tired while making measurements,” project leader Dirk Probian, Senior Development Manager at Schreiner LogiData,” comments on the process with a smile. And that exactly was the objective of developing 3DM—obtaining reproducible, valid measurement results.

The basic idea,” says team leader Hartmut Wiederrecht, “was for us to obtain an automated 360-degree view of RFID performance because radiation varies, depending on the direction of the measurement.” “Using the measuring robot, we always have the same angle, always the same gap, and as a result, can find out at which point and in which direction the inlay delivers the highest performance,” adds Dirk Probian. That’s a key quality characteristic because it’s the only way for the customer to know where the RFID label must be placed for optimal reading.

To start the new year, 3DM as an official “team member” will be able to assist the colleagues from Schreiner LogiData

3DM owes its existence to the creativity of Schreiner’s experts: “The desire for reliable measurements was coupled with a sound play instinct. The available, fully automated industrial systems are simply not designed for our scale and that’s why the idea was born to develop one in-house—and the robotic version was very charming,” says Wiederrecht.

The charming 3DM with a mere size of 30 cm was created in collaboration with a college student. It took about half a year before the system was finished. The special characteristic of the automated helper is that the reader functionality was already integrated into the control software. “Of course, there were stages in the development, such as the selection of the stepping motor, that cost time,” explains Dirk Probian. “After all, the project was about robotics, inverse kinematics, complex matrix calculations—but the outcome is respectable and now state-of-the-art.”

It’s the first fully automated measuring robot to have been developed by Schreiner LogiData. The readings it generates in the RFID laboratory are clearly more precise than those that any employee could deliver with manual measurements. Currently, the reliability of 3DM is still being officially validated.