Everything in Sight: Intralogistics with RFID

SCHREINER PROTECH

Everything in Sight:

Intralogistics with RFID

A smooth workflow between the receiving and the shipping departments calls for perfect interaction between marking, identification, and digitalization. One of the ways to achieve that is the deployment of Schreiner ProTech’s RFID DistaFerr ESD. Combined with a driverless system, the Schreiner label has evolved into an integral component of a unique solution of the ifm group of companies.

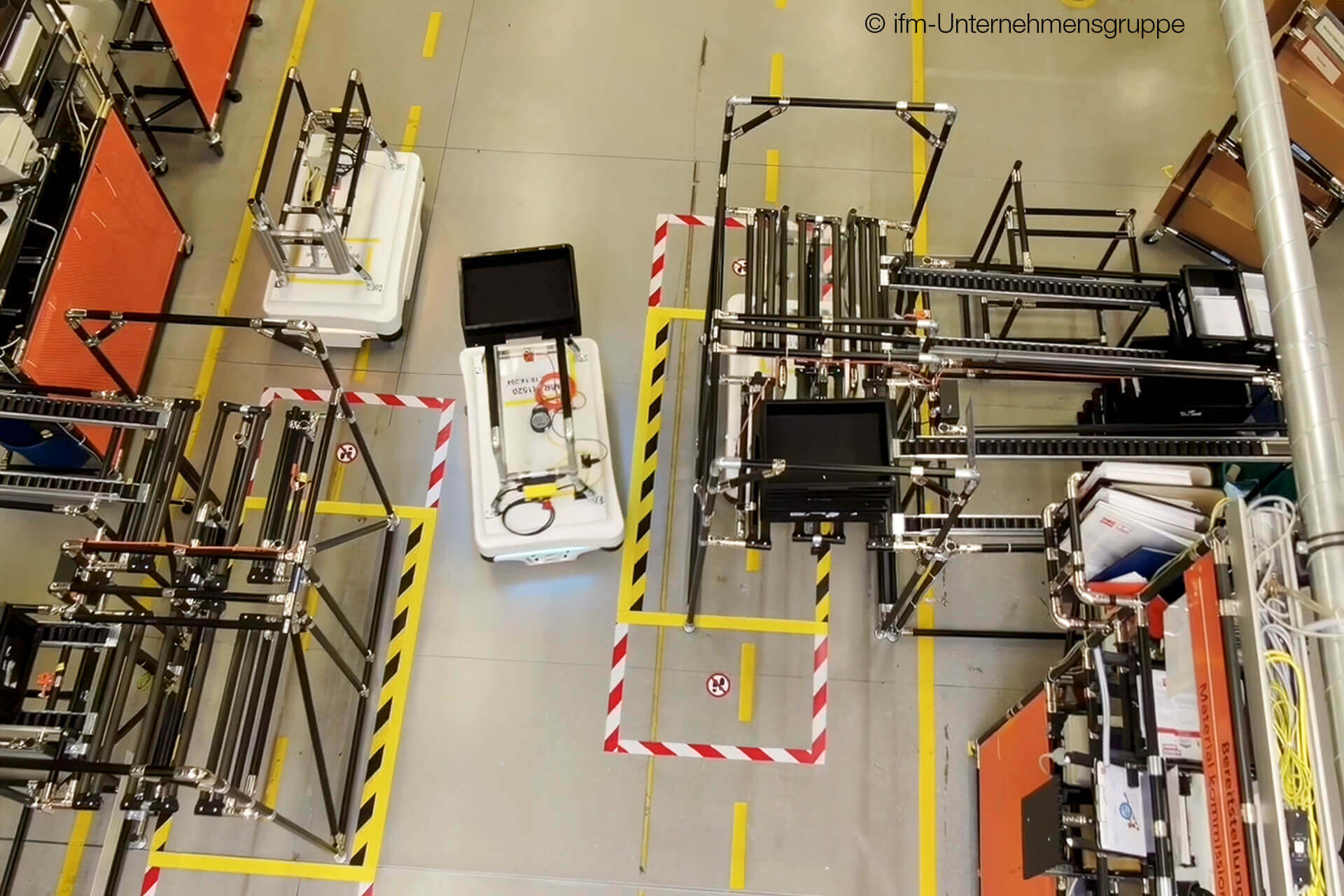

30 kilometers. That’s the distance the small Automated Mobile Robots, or AMR for short, cover day in day out at ifm’s location in Tettnang in the German state of Baden-Württemberg. In the factory hall, the driverless vehicles automatically haul products in ESD containers marked with the Schreiner label from A to B. At defined stops, the AMRs pass a special rack system, a type of gate, where the scheduled container can be dropped off and a new one picked up. “It was crucial,” explains Ulrich Beller, Lean Manager ifm, “for all containers to be uniquely marked and automatically identifiable. The RFID labels were the key to this use case. As a result of now having combined two steps in one process we benefit from massive time savings and increase in efficiency.”

Offering perfect logistics to the customer as a decisive competitive advantage in the marketplace is a core competency of ifm, and the numbers speak for themselves: Due to customized and optimized systems, the company achieves 99% delivery accuracy with 155,000 customers worldwide and around 1.3 million purchase orders per year. Stability and reliability because of perfectly meshed processes—plus clever combinations. “((rfid))-DistaFerr ESD LongRange is not exactly a niche product,” says Katharina Totev, Product Manager RFID at Schreiner ProTech, “but has been developed for a specific use case—that is for application to ESD materials. However, what makes this case special is the combination of our marking and the Automated Mobile Robots from ifm. That combination makes the difference and, consequently, the all-in-one solution unique.”

Digitally tracking all processes starting with incoming goods, avoiding errors within intralogistics, increasing throughput speed, and ensuring customer satisfaction with an optimal delivery rate: With advantages like these, the system is obviously of interest not only to internal logistics in Tettnang but, thanks to the different components, can be easily transferred to other companies as well. Smart, efficient, and transparent.