Happy Birthday, Pressure Compensation Seal!

SCHREINER PROTECH

Happy Birthday, Pressure Compensation Seal!

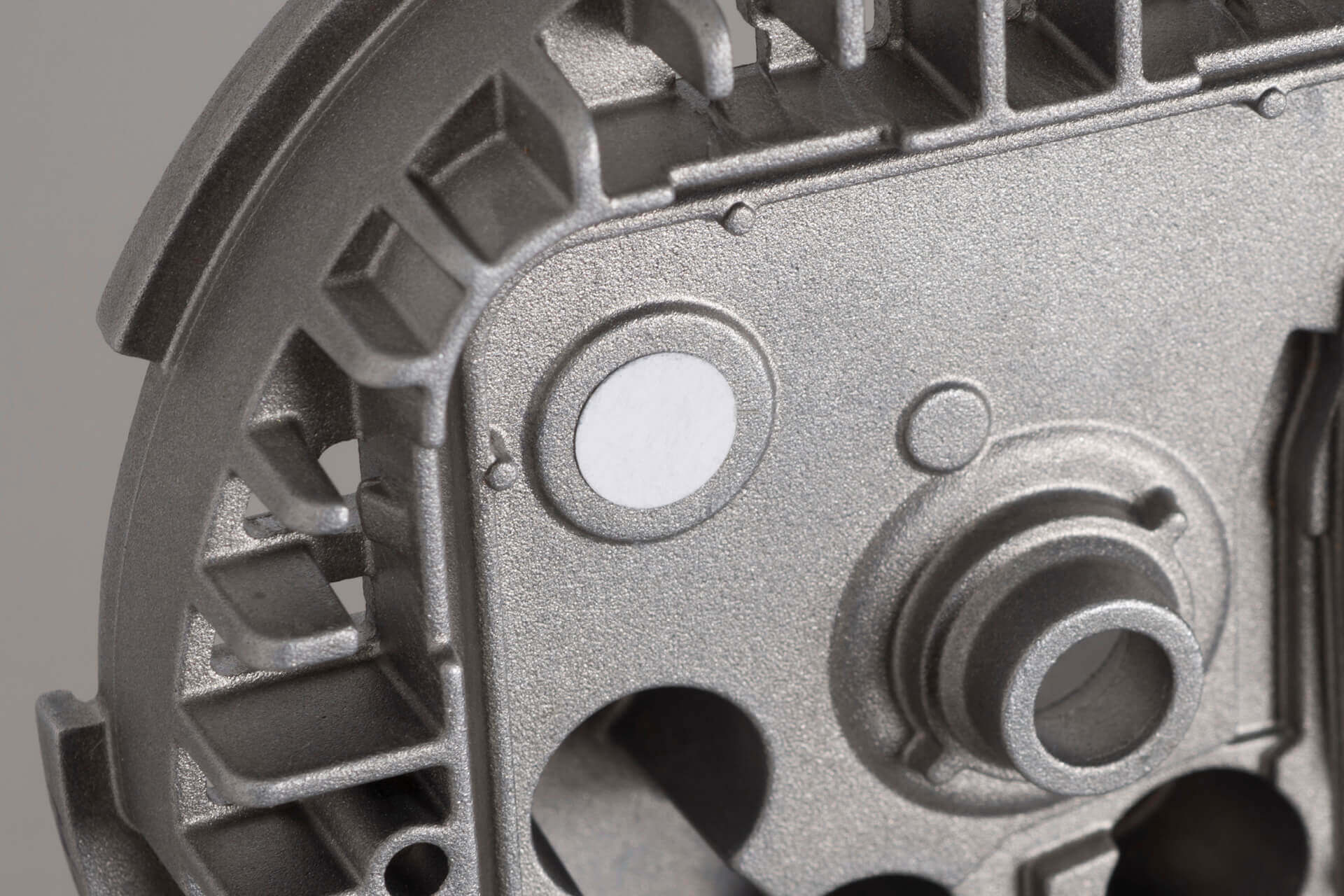

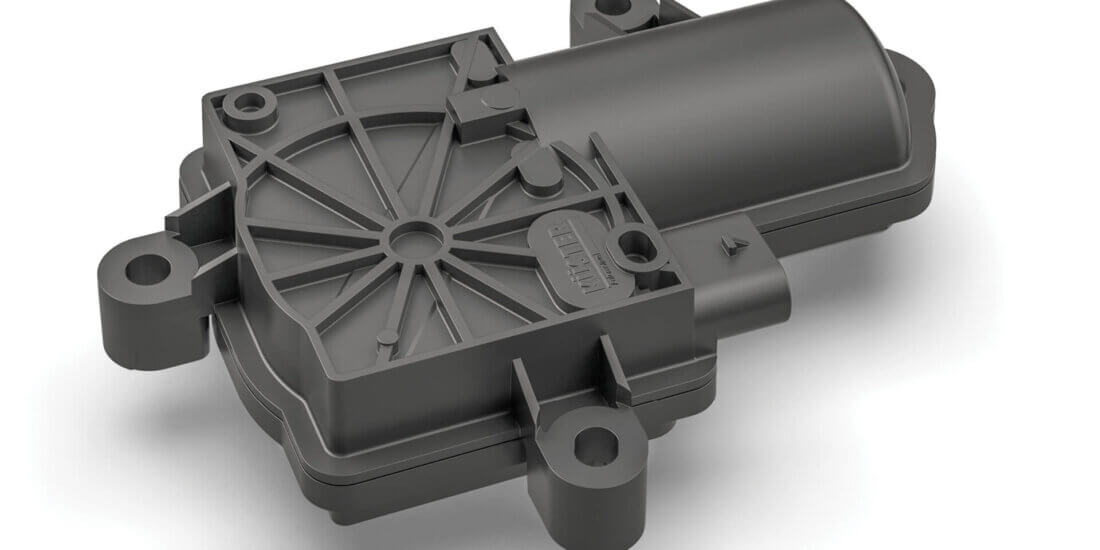

Honestly speaking, they’re unspectacular yet indispensable: Pressure Compensation Seals (PCS). Whether in automobiles or in electric toothbrushes, the range of possible uses for these small components in electronic applications is huge. They’ve been an integral component of Schreiner ProTech’s portfolio for a long time. Now that PCS are celebrating an anniversary, it’s time to briefly look back and ahead.

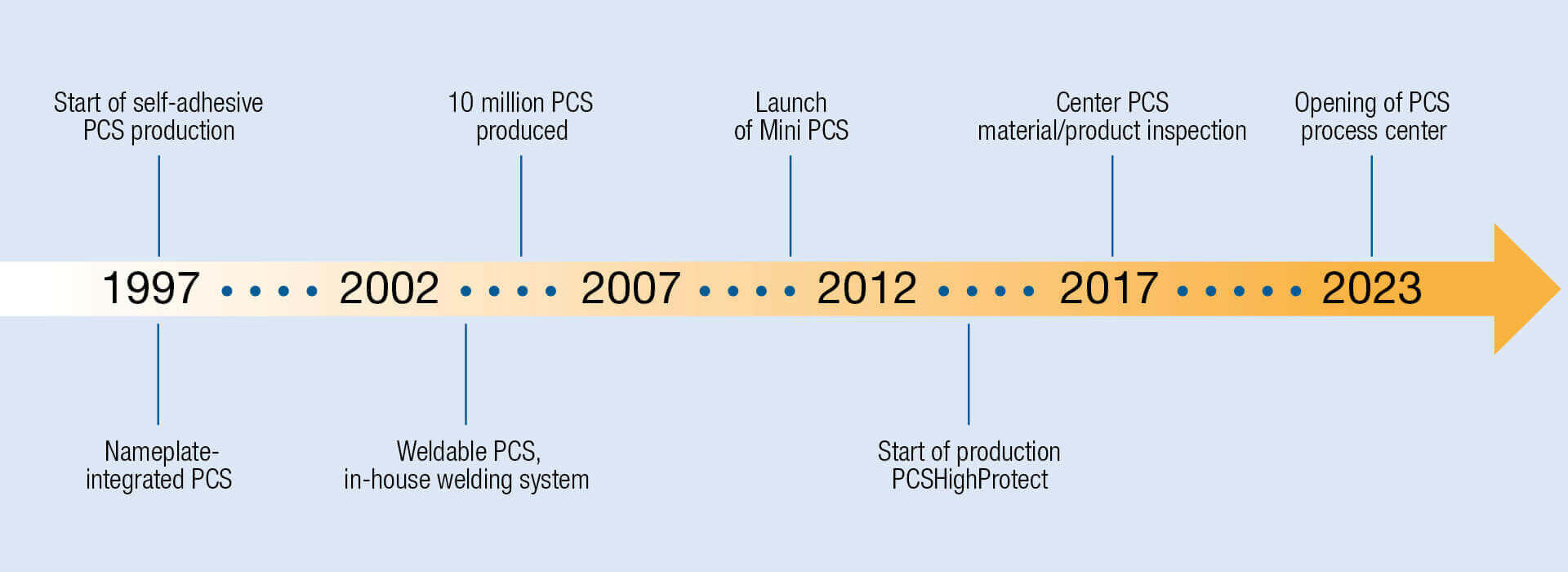

It all started in the mid-nineteen-nineties with a customer’s wish for a gas-permeable yet watertight membrane to be equipped with an adhesive ring for venting electronic control units in automobiles. Numerous trials and discussions with the customer ensued and the product’s name soon emerged, too: Pressure Compensation Seal or PCS for short.

At that time, Schreiner Group did not have any expertise in these specialty materials but, at some point, was awarded the first processing orders using membrane 20-88. For 20 years, it would remain in use as the standard membrane at Schreiner Group. The initial “manifestations” of the PCS tended to be unspectacular.

Those PCS were used for electric garage door drive systems and deep-well sensors, followed by contracts from the automotive sector. Whether as a “nameplate-integrated PCS” or as a “steam jet protection label for adhesive PCS,” the then new product group was picking up momentum.

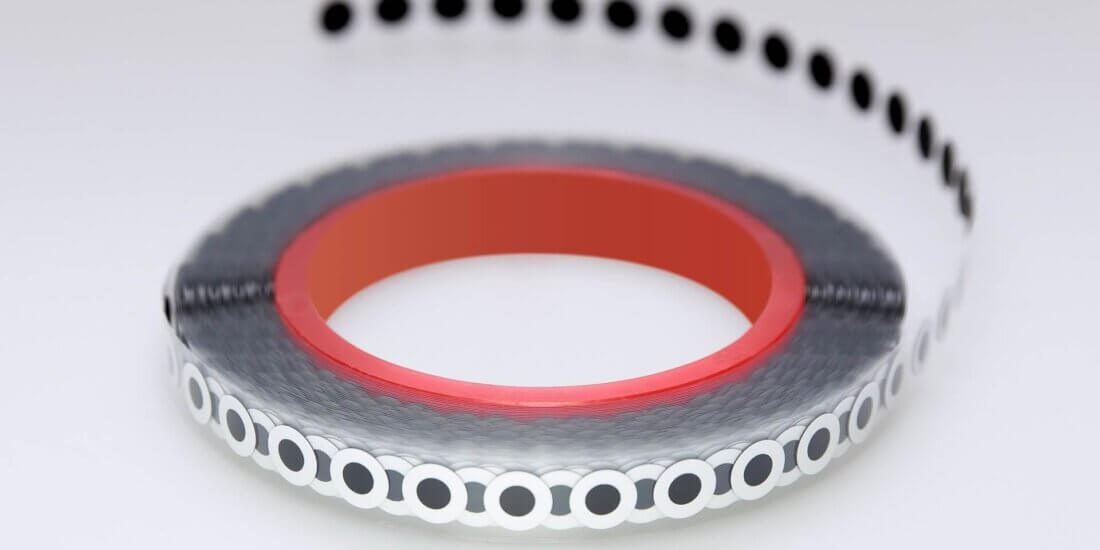

Even so, 25 years ago, it was not foreseeable that the initially small annual volumes of 10,000 PCS would increase to roughly 100 million Pressure Compensation Seals per year. Meanwhile, not only the portfolio has clearly expanded but Schreiner ProTech has established itself in the marketplace as a full-service PCS provider.

Whether system solutions for manual, semiautomatic, and fully automated installation and testing—customers around the world value the tailored and customized solutions.

The constant further development in the PCS area is also noticeable in terms of physical space: while merely an area of 15 square meters and one inspector were required for the initial incoming goods inspections in the 1990s, the PCS department has since grown to fill an entire hall with several machines and employees.

In-house testing methods have been further developed in recent decades as well. Whereas functional tests were initially performed exclusively by customers Schreiner Group, today, has the capabilities for performing the required tests in its own in-house laboratory.

Visually, the PCS has hardly changed in the last quarter of a century, but the requirements to be met by the product have clearly increased due to the wide range of its possible uses. That is one reason why Schreiner ProTech is going to dedicate a specific process center to Pressure Compensation Seals starting in 2023. So, it’s worth staying tuned to see what the next 25 years of PCS will produce.

Pressure Compensation Seals (PCS)

PCS typically have a diameter of just 3 to 30 mm. The special part about a PCS is the membrane located inside the component. It is watertight and dustproof, yet air-permeable. As a result, pressure differences in housings are equalized, the electronics protected against moisture and dirt, and the performance of electronic components ensured.