Top Performance: Medium-size Business Award goes to Schreiner Group

A great honor for the international family business from Oberschleissheim: Schreiner Group has been recognized with the 2025 Bavarian Medium-Size Business Award. The awards ceremony took place in a festive setting at the Munich “Künstlerhaus” at the end of July.

Innovation Award for Top-Class Product

At this year’s FINAT Label Competition, Schreiner Group impressed with the Smart Syringe Box from the Schreiner MediPharm business unit. The smart packaging solution specifically for syringes won the first-place award in the “Innovation” category. As part of the European

Connected for Sustainability

The EU Corporate Sustainability Reporting Directive (CSRD) requires many companies to comprehensively report about their environmental and social impact, and corporate governance. The objective is to achieve transparent and comparable sustainability reporting within the EU. To jointly master these requirements,

Focus on Drug Protection

Biologics, mRNA therapies, antibody drug conjugates (ADCs) as anticancer drugs, and other novel pharmaceuticals are highly effective—but equally sensitive. Reliably protecting them requires more than just suitable primary packaging. At Schreiner MediPharm, Corinna Endres, Product Manager Drug Protection, oversees tailored

New Dimension in Printing

This year, Schreiner Group started operating a new high-performance printing machine in Oberschleissheim that sets new standards: a FlexoHybrid 1,200 dpi combining the advantages of digital printing with those of classic flexographic printing technology— and making it a key component

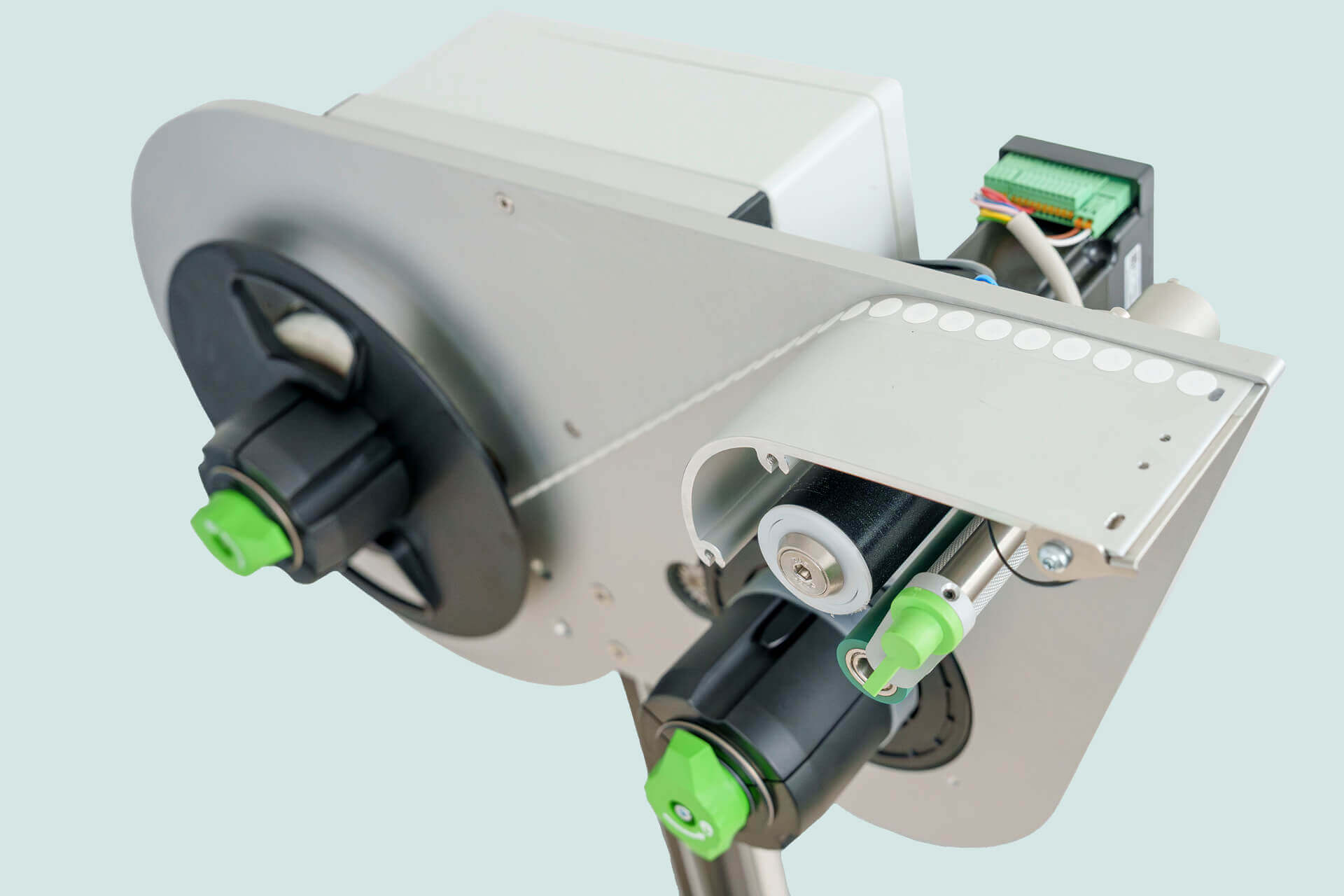

Hello, Servo!

Labels with RFID chips, stiff, thick materials, or sensitive functional layers make high demands on the dispensing process. However, classic labeling/processing systems can damage sensitive materials and RFID chips due to multiple deflections around small rollers. That’s where a new

New Leadership for Technology and Innovation Management

Change at the helm of Technology and Innovation Management (TIM): Dr. Jens Vor der Brüggen, who had been leading Research and Development (R&D) for many years, assumed responsibility for TIM from Robert Weiss this summer. Robert Weiss will support the

The pilot plant: Innovation engine in the background

Whether hybrid technology (the combination of different printing methods), laser cutting, or sustainable materials—before new manufacturing technologies are adopted for regular production at Schreiner Group they pass through a central testing facility: the company’s in-house pilot plant. The things being

PCS HighProtect Check

Whether at our VentingXperience event, in customer conversations, or in exchanges with developers and buyers: Our continuously growing PCS HighProtect product group is in high demand. That’s hardly surprising because the requirements for pressure compensation, protection, and traceability have clearly

Time for an Update

RFID technology keeps developing further. To ensure that Schreiner Group’s customers will continue to benefit from state-of-the-art technology, Schreiner’s LogiData competence center continuously optimizes existing products and makes them fit for the future. Specifically, that means the ground’s been cleared